中国激光, 2020, 47 (1): 0102004, 网络出版: 2020-01-09

基于NSGA-Ⅱ算法的同轴送粉激光熔覆工艺多目标优化  下载: 1133次

下载: 1133次

Multi-Objective Optimization of Coaxial Powder Feeding Laser Cladding Based on NSGA-II

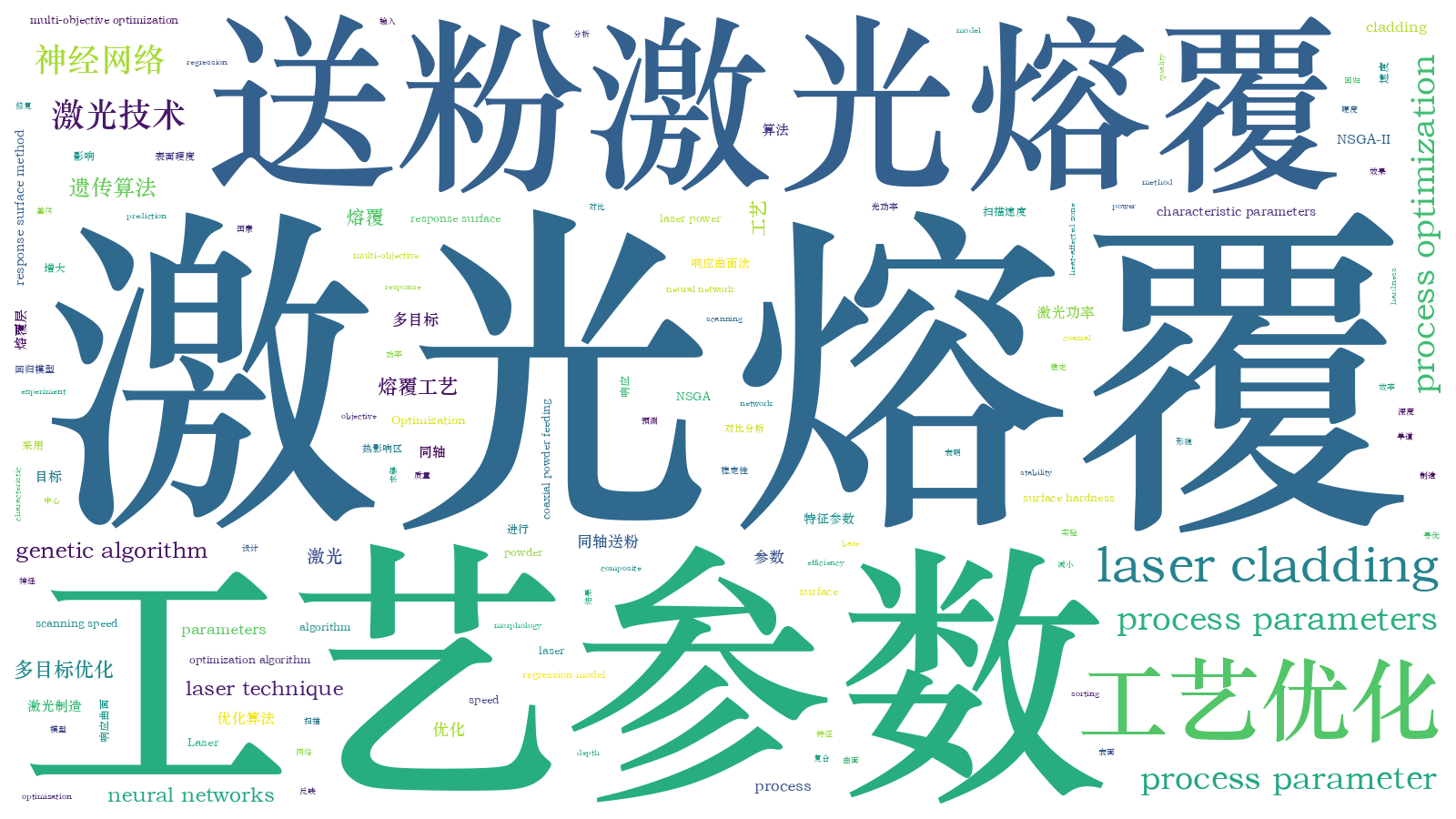

激光技术 激光熔覆 工艺参数 神经网络 遗传算法 工艺优化 laser technique laser cladding process parameter neural networks genetic algorithm process optimization

摘要

同轴送粉激光熔覆工艺的稳定性受诸多因素的影响,其工艺参数难以寻优。通过设计以工艺参数(激光功率、送粉速度、扫描速度)为输入、以反映熔覆层形貌和质量的特征参数为响应的中心复合实验,对比分析了响应曲面法的回归模型与神经网络对单道熔覆结果的预测效果。采用多目标优化算法NSGA-II对三个工艺参数进行优化求解。结果表明:采用优化后的参数进行激光熔覆的修复件表面硬度增大了17.11%,基体热影响区深度减小了13.90%,熔覆效率增大了6.10%。

Abstract

The stability of coaxial powder feeding laser cladding process is affected by many factors, which makes it difficult to estimate the optimal process parameters. This study designs a central composite experiment, which considers the process parameters (laser power, powder feeding speed, and scanning speed) as input and outputs the characteristic parameters that reflect the cladding morphology and quality. The regression model and neural network in the response surface method are applied to the prediction of the single-pass cladding results, and their effects are compared. Based on this, a multi-objective optimization algorithm, i.e., the non-dominated sorting genetic algorithm II (NSGA-II), is used to optimize the three aforementioned process parameters. The results denote that the optimized process parameters can improve the surface hardness of the repaired parts by 17.11%, reduce the depth of the base heat-affected zone by 13.90%, and improve the cladding efficiency by 6.10%.

赵凯, 梁旭东, 王炜, 杨萍, 郝云波, 朱忠良. 基于NSGA-Ⅱ算法的同轴送粉激光熔覆工艺多目标优化[J]. 中国激光, 2020, 47(1): 0102004. Kai Zhao, Xudong Liang, Wei Wang, Ping Yang, Yunbo Hao, Zhongliang Zhu. Multi-Objective Optimization of Coaxial Powder Feeding Laser Cladding Based on NSGA-II[J]. Chinese Journal of Lasers, 2020, 47(1): 0102004.