中国激光, 2017, 44 (1): 0102013, 网络出版: 2017-01-10

带热障涂层的高温合金飞秒激光旋切打孔  下载: 1459次

下载: 1459次

Trepanning of Supper-Alloy with Thermal Barrier Coating Using Femtosecond Laser

激光制造 激光加工 飞秒激光旋切开孔 热障涂层 重铸层 laser manufacturing laser machining femtosecond laser trepanning thermal barrier coating recast layer

摘要

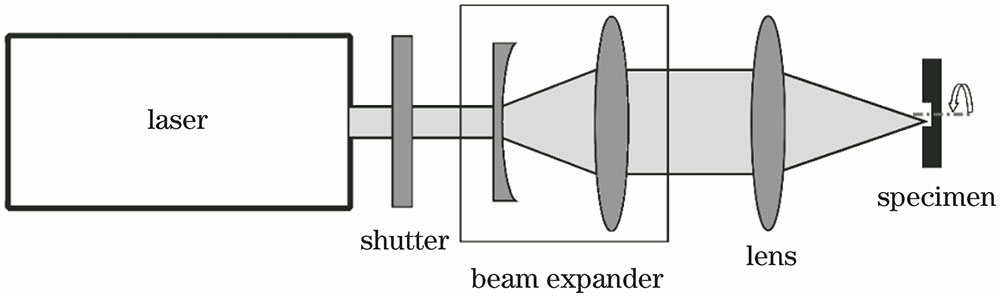

针对燃气轮机叶片气膜孔传统加工方法存在的缺陷, 采用飞秒激光旋切带热障涂层的高温合金加工气膜孔, 获得了无裂纹、无附着残渣及无重铸层的锥孔。结合飞秒激光加工过程中材料的去除机理, 分析得出:等角速度旋切造成的孔锥度较大; 材料的去除过程为绝热冷却过程, 即与周边材料几乎没有热交换, 未发生基体材料熔化后重新凝固形成重铸层的过程。然而, 在孔的入口发现黑色附着物, 随着加工次数的增加, 逐步覆盖整个入口边缘的部分。试验过程中可收集到含有镍、锆、氧等元素的纳米颗粒, 证明被去除的材料通过液相爆破的方式以纳米颗粒的形式快速离开基体, 从而解释了加工后在孔壁未发现大量附着残渣粘连的原因。相对于低速单层旋切, 高速多层旋切加工效率更高。

Abstract

To avoid the defects of conventional methods to manufacture gas film holes for gas turbine blades, femtosecond laser is applied to trepanning supper-alloy with thermal barrier coating, and holes without crack extension, attached debris, and recast layer are obtained. Combined with the material removal mechanism of femtosecond laser drilling, it can be obtained through analysis that the taper of holes is larger under trepanning with same angular speed. In addition, the process of material removal is considered as adiabatic cooling, that is, thers is nearly no heat exchange between processing material and the surrounding material. Therefore, the process of substrate material melting and re-solidifying to form a recast layer does not happen. However, black attachments are found around the hole entrance, and as the cutting times increase, they gradually cover the entire part of the entrance edge. Nanoparticles with elements nickel, zirconium and oxygen are collected during processing, which proves that the removed material leaves the substrate quickly in nanoparticles through the phase explosion mechanism. This explains why no attached debris is found on the pore wall. Compared with low-speed single layer cutting, high-speed multilayer cutting is much more efficient.

张学谦, 邢松龄, 刘磊, 李勇, 佟浩, 邹贵生. 带热障涂层的高温合金飞秒激光旋切打孔[J]. 中国激光, 2017, 44(1): 0102013. Zhang Xueqian, Xing Songling, Liu Lei, Li Yong, Tong Hao, Zou Guisheng. Trepanning of Supper-Alloy with Thermal Barrier Coating Using Femtosecond Laser[J]. Chinese Journal of Lasers, 2017, 44(1): 0102013.