Chinese Optics Letters, 2018, 16 (1): 011401, Published Online: Jul. 17, 2018

Ablation enhancement by defocused irradiation assisted femtosecond laser fabrication of stainless alloy  Download: 908次

Download: 908次

Abstract

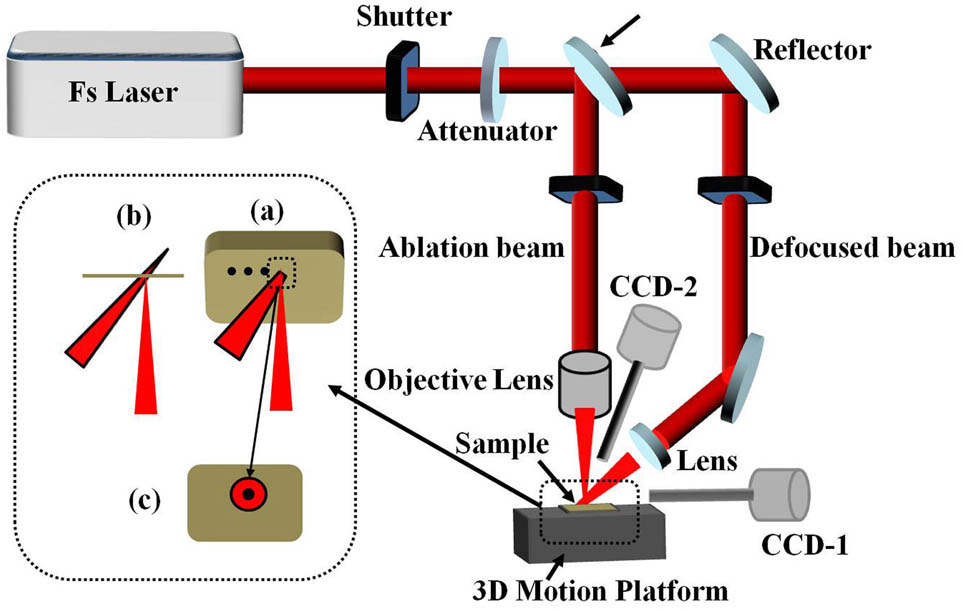

We evaluate the effects of the holes geometry drilled by a femtosecond laser on a stainless alloy with various defocused irradiation time, which ranges from 0 min to 1 h. The laser ablation efficiency is increased by a factor of 3 when the irradiation time is elevated from 0 to 30 min. Also, the morphology of the hole is observed by a scanning electron microscope, where the result indicates that the defocused irradiation time has a significant influence on the morphology changes. The reason for such changes is discussed based on the pretreatment effect and the confined plasma plume. As an application example, the microchannel is fabricated by a femtosecond laser combined with the defocused irradiation to demonstrate the advantage of the proposed method in fabricating functional structures.

Dongkai Chu, Kai Yin, Xinran Dong, Zhi Luo, Yuxin Song, Ji'an Duan. Ablation enhancement by defocused irradiation assisted femtosecond laser fabrication of stainless alloy[J]. Chinese Optics Letters, 2018, 16(1): 011401.