激光与光电子学进展, 2018, 55 (1): 011408, 网络出版: 2018-09-10

陶瓷材料激光增材制造的研究现状及展望  下载: 2438次封面文章

下载: 2438次封面文章

Status and Prospect of Laser Additive Manufacturing of Ceramic Materials

摘要

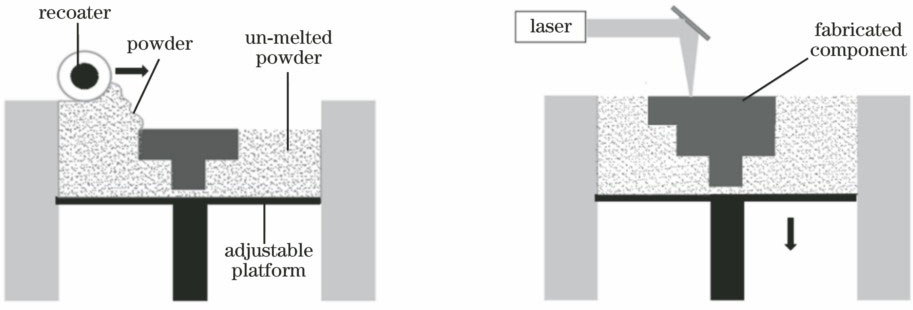

近年来,激光在增材制造技术中的应用丰富了增材制造技术类别,拓宽了精度范围和应用领域。概括了激光增材制造(LAM)陶瓷材料技术的类别、原理和特点,介绍了其应用和研究现状。另外,分析了各种技术存在的不足,并对陶瓷材料的LAM的发展前景进行了展望。

Abstract

The application of laser in the additive manufacturing technique has enriched the additive manufacturing technique category and broadened the precision range and application fields. The category, principle and characteristics of the laser additive manufacturing (LAM) techniques of ceramic materials are summarized and its applications and research status are introduced. In addition, the existing problems of the above techniques are analyzed, the future development of LAM of ceramic materials is prospected.

倪荣萍, 钱滨, 刘畅, 邱建荣. 陶瓷材料激光增材制造的研究现状及展望[J]. 激光与光电子学进展, 2018, 55(1): 011408. Ni Rongping, Qian Bin, Liu Chang, Qiu Jianrong. Status and Prospect of Laser Additive Manufacturing of Ceramic Materials[J]. Laser & Optoelectronics Progress, 2018, 55(1): 011408.