激光与光电子学进展, 2018, 55 (4): 041405, 网络出版: 2018-09-11

工艺参数对H13钢激光选区熔化成形缺陷的影响  下载: 1610次

下载: 1610次

Influence of Process Parameters on Forming Defects of H13 Steel Processed by Selective Laser Melting

激光技术 激光选区熔化 工艺参数 成形缺陷 H13钢 laser technique selective laser melting process parameters forming defects H13 steel

摘要

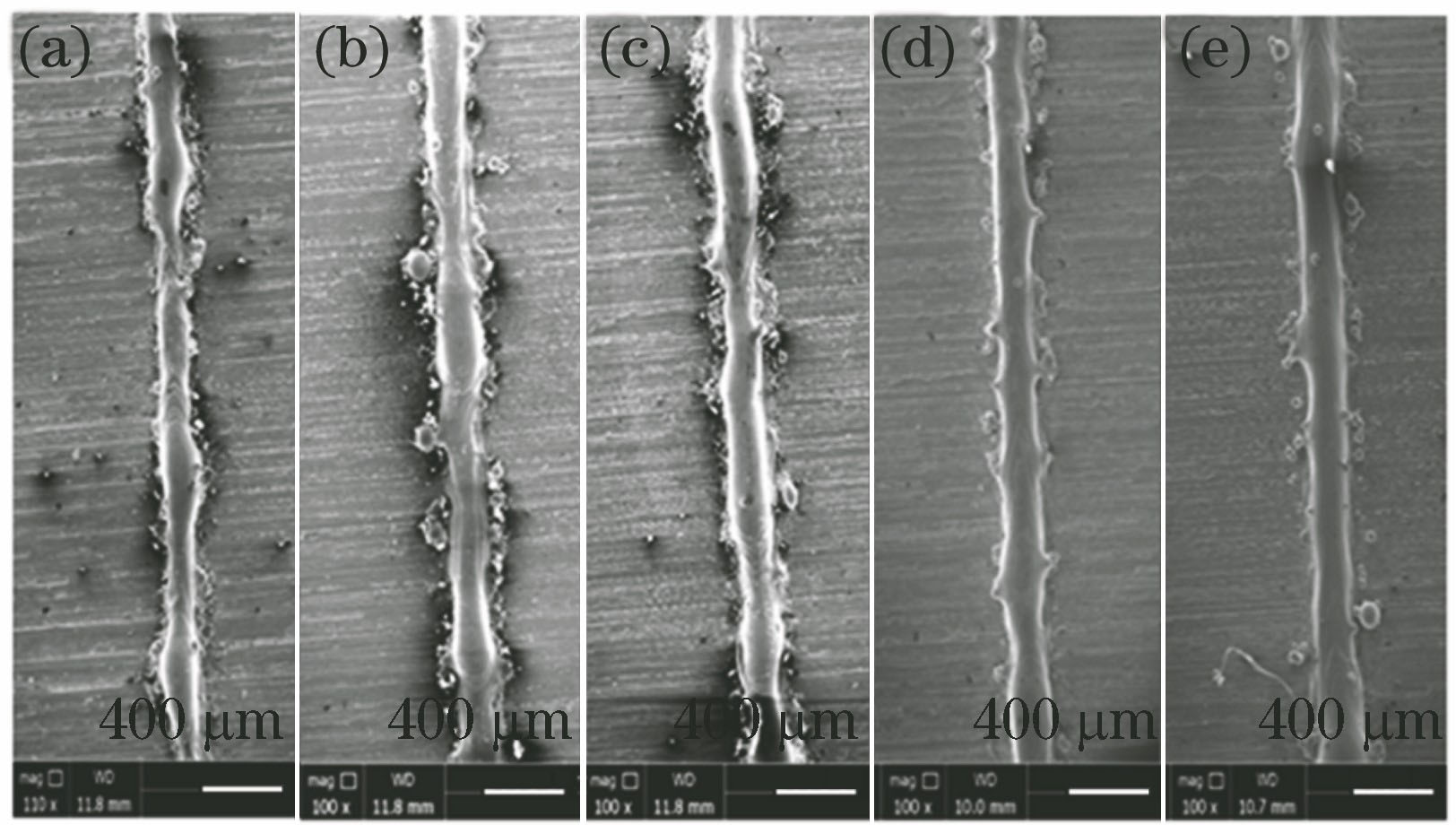

对H13钢粉末材料进行了激光选区熔化(SLM)成形,通过改变激光功率、扫描速度、扫描间距、扫描方式等参数,对比研究了工艺参数对试件成形缺陷的影响规律。结果表明,在一定激光功率和扫描速度范围内,增大激光功率或减小扫描速度有利于试件的成形;过大或过小的扫描间距都会影响成形质量,形成气孔或未熔合缺陷;相对于Z型正交扫描和单X 方向扫描, S型正交扫描的成形件质量最好。

Abstract

The formation of H13 steel powder material is conducted by using the selective laser melting(SLM) technology, and the influence rules of process parameters on the forming defects are obtained via a comparative study by changing the parameters including laser power, scanning speed, scanning pitch and scanning method. The results show that, in a certain range, the increase of laser power or the decrease of scanning speed is beneficial to the formation of parts. A too large or too small scanning pitch has a significant impact on the forming quality and thus the pores or fusion-incomplete defects occur. The quality of forming parts under S-shaped orthogonal scanning is the best if compared with those under Z-shaped orthogonal scanning and single X-direction scanning.

徐锦岗, 陈勇, 陈辉, 杨冰. 工艺参数对H13钢激光选区熔化成形缺陷的影响[J]. 激光与光电子学进展, 2018, 55(4): 041405. Jingang Xu, Yong Chen, Hui Chen, Bing Yang. Influence of Process Parameters on Forming Defects of H13 Steel Processed by Selective Laser Melting[J]. Laser & Optoelectronics Progress, 2018, 55(4): 041405.