光学学报, 2018, 38 (7): 0722001, 网络出版: 2018-09-05

光刻机照明光场均匀性高精度校正方法研究  下载: 1217次

下载: 1217次

High Precision Correction Method of Illumination Field Uniformity for Photolithography Illumination System

光数据存储 光刻机 照明系统 均匀性校正 optical data storage photolithography illumination system uniformity correction

摘要

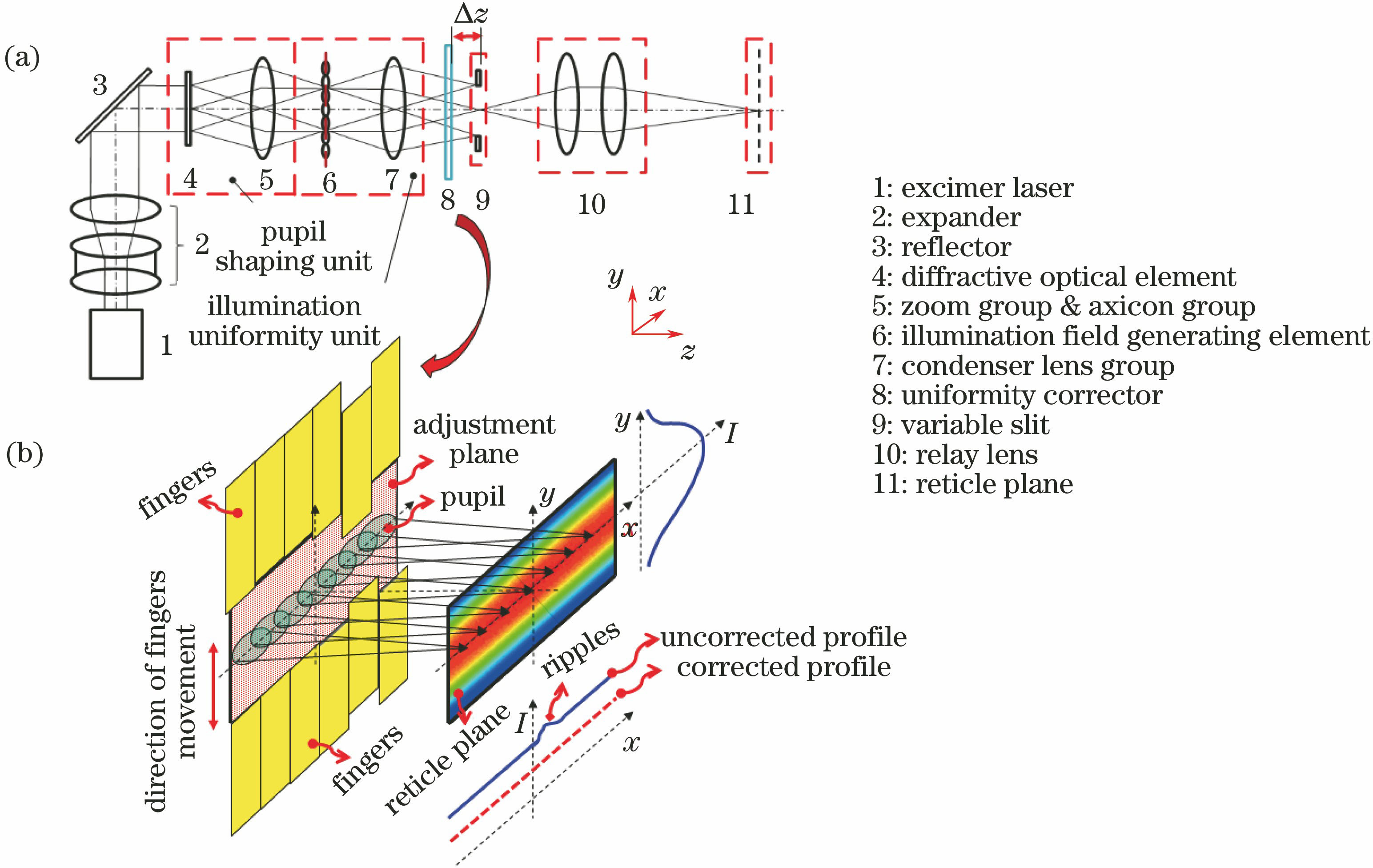

提出了应用于光刻机照明系统照明光场均匀性的高精度校正方法,该方法通过优化手指阵列式均匀性校正器中校正手指前端的形状及其排布方式来提高校正能力和精度。仿真结果表明:当校正手指错开排布时,手指阵列式均匀性校正器的校正精度优于0.2%;当校正手指的前端有倒斜角且双层错开排布时,手指阵列式均匀性校正器的校正精度优于0.16%,比常规手指阵列式均匀性校正器的校正精度提高约一倍。

Abstract

A high precision correction method of illumination field uniformity for photolithography illumination system is proposed. The correction ability and accuracy are improved by the optimization of the fingers' fore-end shape and arrangement of the finger array uniformity corrector. The simulation results show that the correction accuracy of the finger array uniformity corrector is better than 0.2%, when fingers are staggered arrangement. In addition, the correction accuracy of the finger array uniformity corrector is better than 0.16%, when fingers are chamfered, staggered and double layouts arrangement, which is about twice as high as general finger array uniformity corrector.

程伟林, 张方, 林栋梁, 曾爱军, 杨宝喜, 黄惠杰. 光刻机照明光场均匀性高精度校正方法研究[J]. 光学学报, 2018, 38(7): 0722001. Weilin Cheng, Fang Zhang, Dongliang Lin, Aijun Zeng, Baoxi Yang, Huijie Huang. High Precision Correction Method of Illumination Field Uniformity for Photolithography Illumination System[J]. Acta Optica Sinica, 2018, 38(7): 0722001.