中国激光, 2018, 45 (7): 0702004, 网络出版: 2018-09-11

基于固有应变法的激光选区熔化成形变形趋势预测  下载: 1046次

下载: 1046次

Deformation Prediction of Metal Selective Laser Melting Based on Inherent Strain Method

激光技术 激光选区熔化 变形预测 固有应变 生死单元 laser technique selective laser melting deformation prediction inherent strain birth-death element

摘要

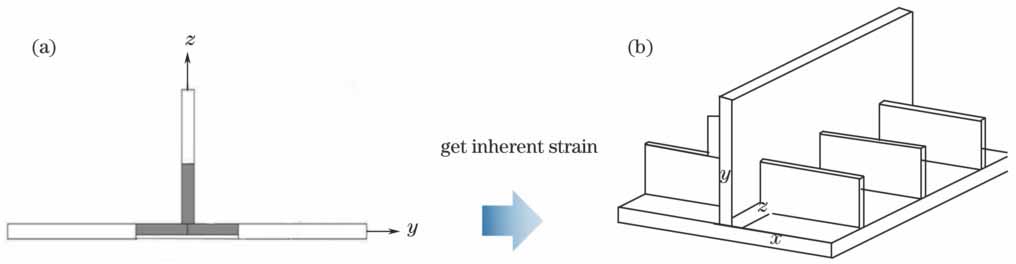

针对激光选区熔化(SLM)成形过程中易发生翘曲变形的问题,建立了一种“热源-局部-结构件”三级递进模型,采用生死单元法模拟了SLM成形中层层叠加的过程,并逐层施加固有应变,得到了宏观结构件SLM成形的变形趋势预测结果。将仿真结果与实际成形件进行对比,结果表明,固有应变有限元法能够有效预测SLM成形件的变形量。

Abstract

As for the problem that there occur warpage and deformation in the selective laser melting (SLM) forming process, a three-level progressive model of heat source-locality-structural parts is established and the layer by layer building process in SLM forming is simulated by the birth-death element method. The inherent strain is applied layer by layer to obtain the deformation prediction results of SLM forming of macroscopic structural parts. The comparison between the simulation results and the actual molded parts shows that the inherent strain finite element method can be used to effectively predict the deformation of SLM forming parts.

倪辰旖, 张长东, 刘婷婷, 廖文和. 基于固有应变法的激光选区熔化成形变形趋势预测[J]. 中国激光, 2018, 45(7): 0702004. Chenyi Ni, Changdong Zhang, Tingting Liu, Wenhe Liao. Deformation Prediction of Metal Selective Laser Melting Based on Inherent Strain Method[J]. Chinese Journal of Lasers, 2018, 45(7): 0702004.