光学学报, 2018, 38 (8): 0815011, 网络出版: 2018-09-06

基于自动阈值的窄间隙端接焊缝识别技术  下载: 995次

下载: 995次

Recognition of Narrow-Gap Edge Welding Seam Based on Autonomous Threshold Value

机器视觉 窄间隙 自动阈值 特征点检测 端接焊缝 machine vision narrow gap autonomous threshold feature points extracting edge welding seam

摘要

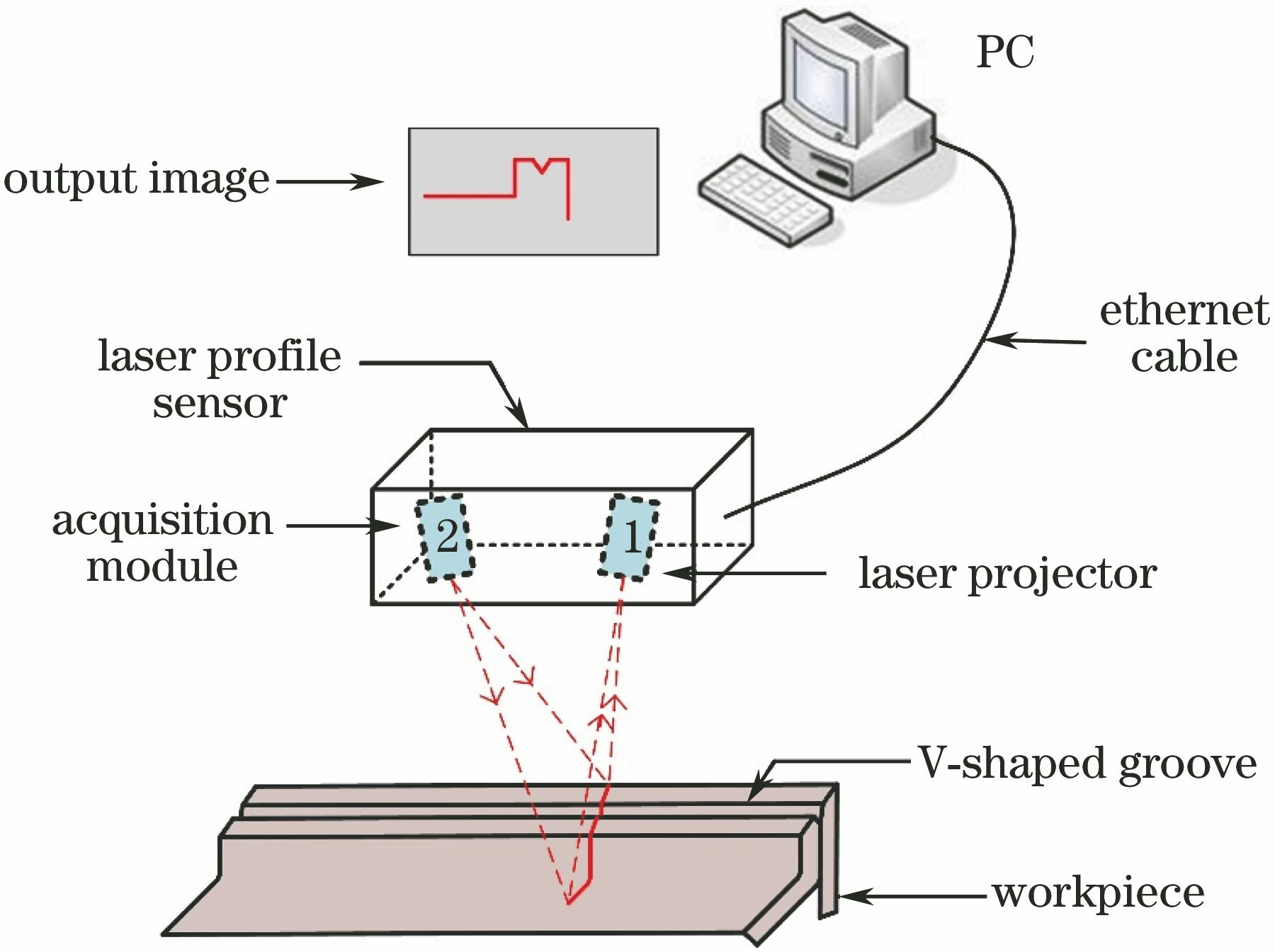

特征点提取是焊缝视觉检测与定位的关键技术,特别是针对实际生产中间隙较小,尤其是超窄间隙的焊缝位置,现阶段的处理算法往往无法保证提取精度,误差大;对于一些间隙极小的细节位置甚至会自动忽略。本文针对端接接头提出一种基于自动阈值处理的自适应中值滤波算法和特征点提取算法对激光扫描图像进行处理的焊缝识别技术:在传统的中值滤波法的基础上,通过计算局部数据点的均值和方差确定有效阈值范围,在剔除噪声点的同时很好地保护了焊缝图像窄间隙细节特征;提出一种“细节放大”的特征点提取算法,将图像细节进行放大,增大窄间隙特征点与周围数据点的差异,显著降低提取难度;利用特征点时域分析,进一步将误差减小到原来的1/

5

Abstract

Feature point extraction is the key technology for visual detection and location of weld seam, especially for micro gap in commercial production. Most of the current methods have considerable errors and cannot guarantee the highly-required extracting precision, even fail to recognize the position of micro gaps. Based on autonomous threshold value, the improved median filtering algorithm and feature points extraction algorithm are proposed to deal with the scanning image. Firstly, on the basis of traditional median filtering, the range of threshold value is set by calculating regional mean value and variance, this method is good at protecting the image detail of narrow gap as well as removing noise points. Then, a new method named magnifying details by threshold value is proposed. This method enlarges the gap between feature points of micro gap and nearby data, which enhances seam image details and makes the process of extraction easier. Finally, the error is reduced to 1/

5 of that before utilizing time-domain analysis. Experimental results show that this method meets the requirement of high precision, which can greatly recognize the weld seam varying from 0.1 mm to 0.5 mm with an error less than 0.08 mm. It also has the advantages of good adaptability, strong anti-interference ability along with great practical significance in the field of automatic welding of narrow gap.

雷正龙, 沈健雄, 黎炳蔚, 周恒, 陈彦宾. 基于自动阈值的窄间隙端接焊缝识别技术[J]. 光学学报, 2018, 38(8): 0815011. Zhenglong Lei, Jianxiong Shen, Bingwei Li, Heng Zhou, Yanbing Chen. Recognition of Narrow-Gap Edge Welding Seam Based on Autonomous Threshold Value[J]. Acta Optica Sinica, 2018, 38(8): 0815011.