光学学报, 2018, 38 (10): 1022002, 网络出版: 2019-05-09

射流抛光中生成高斯型去除函数的数学建模方法  下载: 850次

下载: 850次

Mathematical Modeling Method for Generation of Gaussian-Type Removal Function in Fluid Jet Polishing

光学设计 射流抛光 数学模型 高斯型去除函数 optical design fluid jet polishing mathematical model Gaussian-type removal function

摘要

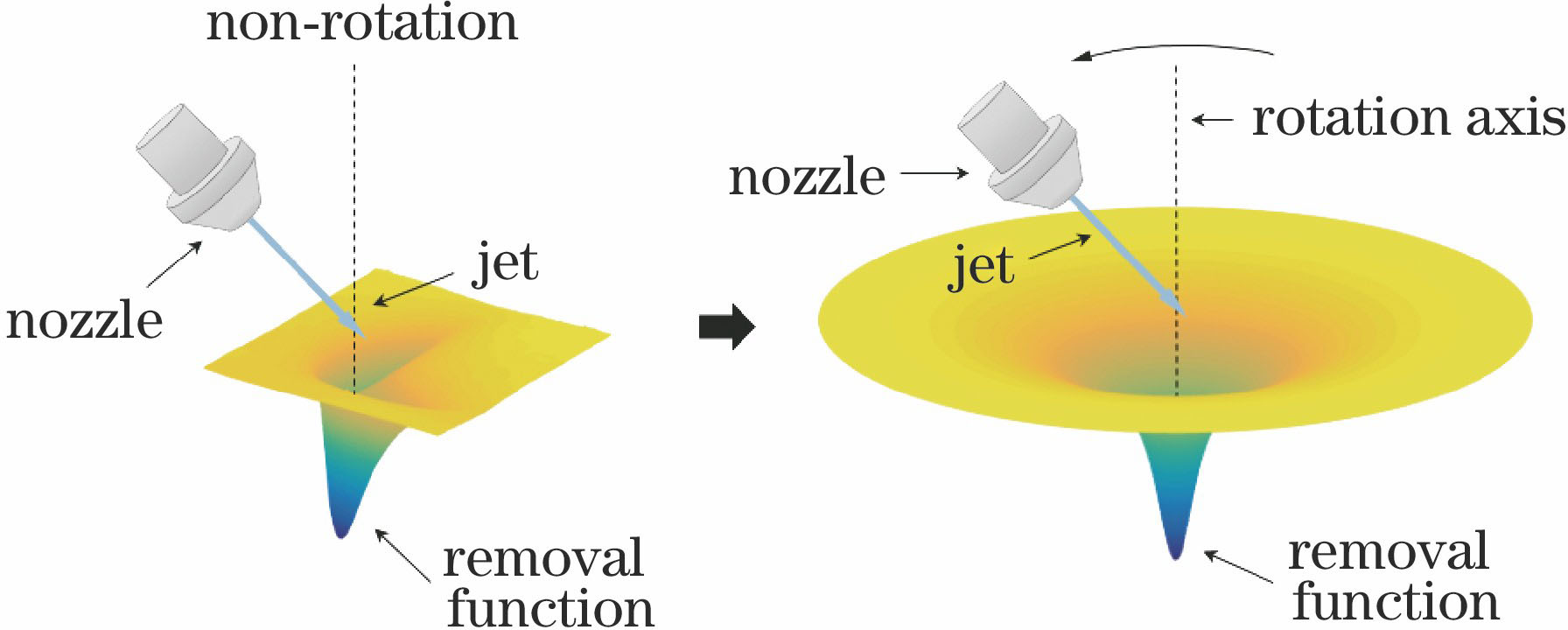

提出了一种高斯型去除(GTR)函数生成过程的数学建模方法。基于环路积分的思路,建立了一种旋转扫掠生成GTR函数的数学模型,明确了喷嘴高度为决定GTR函数形貌的关键工艺参数,验证了模型的正确性。在该模型的指导下,进一步研究了生成GTR函数的喷嘴高度范围和GTR函数的形貌变化规律,发现当回转中心与定点斜入射去除函数最深点重合时,生成的去除函数最接近理想高斯型。这对实际加工中工艺参数的优化具有理论指导意义。

Abstract

A numerical modeling method for the generation of a Gaussian-type removal (GTR) function is proposed. Based on the idea of the loop integration, a mathematical model for the generation of GTR function by rotating sweep is established. It is clarified that the nozzle height is the key process parameter to determine the GTR function profile and the validity of this model is also verified. Under the guidance of this model, the nozzle height range for the generation of GTR function and the change law of GTR function profiles are further investigated, and it is found that the removal function obtained when the gyration center coincides with the deepest point of a removal function with a fixed oblique incidence is the closest to an ideal GTR function, which provides a theoretical guidance in the optimization of process parameters for the practical fabrication.

王中昱, 张连新, 孙鹏飞, 李建, 尹承真. 射流抛光中生成高斯型去除函数的数学建模方法[J]. 光学学报, 2018, 38(10): 1022002. Zhongyu Wang, Lianxin Zhang, Pengfei Sun, Jian Li, Chengzhen Yin. Mathematical Modeling Method for Generation of Gaussian-Type Removal Function in Fluid Jet Polishing[J]. Acta Optica Sinica, 2018, 38(10): 1022002.