激光与光电子学进展, 2018, 55 (11): 111404, 网络出版: 2019-08-14

基于遗传算法的激光切割镍基合金质量优化  下载: 896次

下载: 896次

Quality Optimization of Laser-Cutted Ni-Based Alloys Based on Genetic Algorithm

激光技术 激光切割 神经网络 遗传算法 镍基合金 工艺参数 laser technique laser cutting neural networks genetic algorithm nickel-based alloy process parameters

摘要

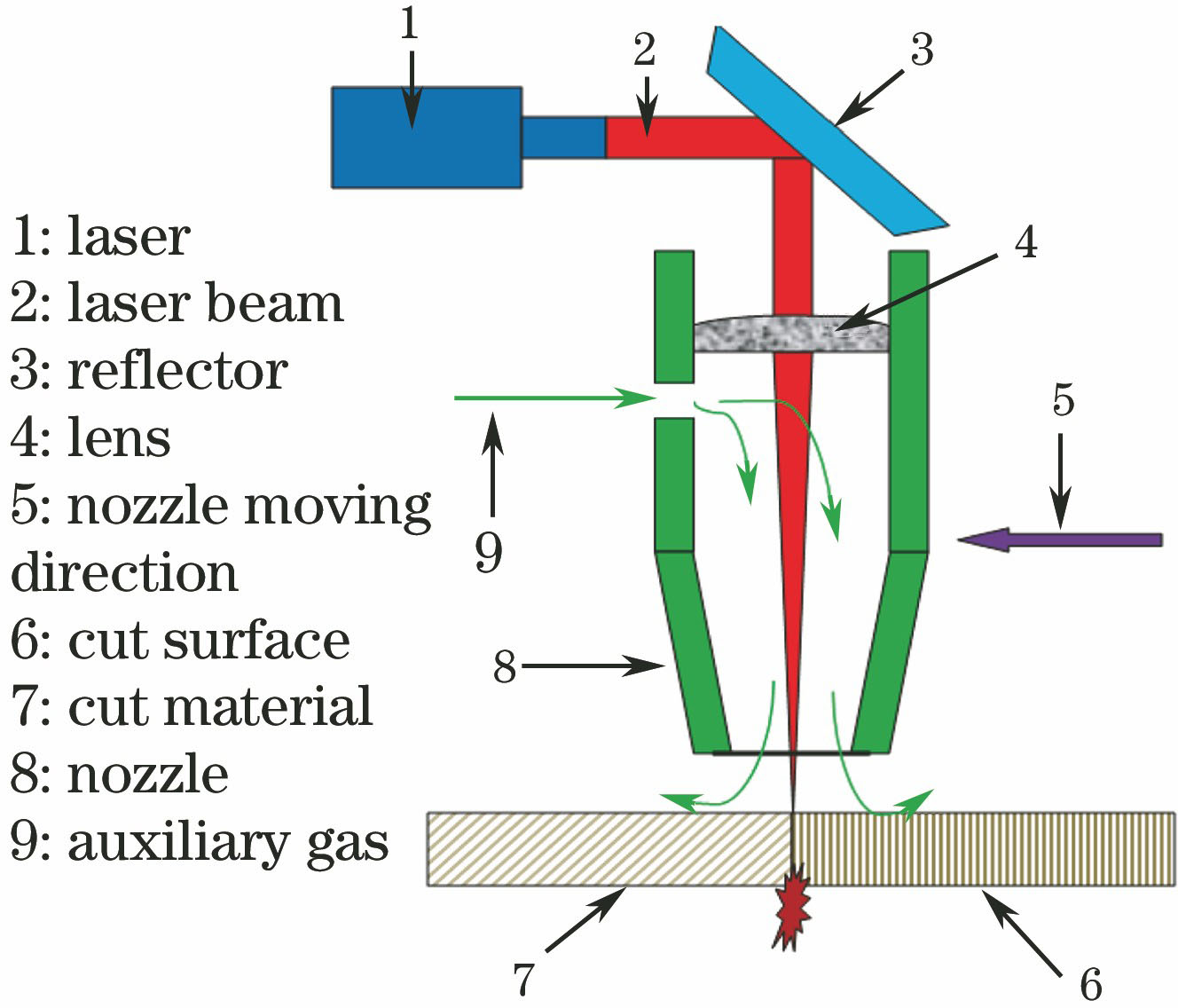

基于人工神经网络,对激光切割镍基合金样本进行了训练函数拟合,以电流、脉宽、切速及离焦量作为输入向量,以挂渣宽度、切缝宽度及切割完整度的综合评分作为输出向量,找出了最小误差的隐含层节点,以此模型预测激光切割质量,得到最大误差为7.66%,最小误差为-0.32%。以综合评分作为遗传算法的适应度值,在实际应用的工艺参数范围内随机选择了50个种群作为最初寻优群体,对其进行交叉、变异和迭代等操作,寻找最优适应度值及对应的工艺参数。理论预测的最优适应度值为98.41,实际值为89.53,误差为9.03%。该验证样本的质量明显高于25个实验样本的,挂渣平均宽度为81.5 μm,切缝平均宽度为164 μm。

Abstract

Based on an artificial neural network, the training function fitting of the laser-cutted Ni-based alloy samples is conducted. With the current, pulse width, cutting speed and defocusing amount as the input vectors and the comprehensive score of the slag width, kerf width, and cutting integrity as the output vector, the hidden layer node with the minimum error is found. Based on this model, the laser cutting quality is predicted. The maximum error is 7.66% and the minimum error is -0.32%. With the comprehensive score as the fitness value of the genetic algorithm, 50 species within the range of the practical process parameters are randomly selected as the initial optimal group. The treatments such as crossover, mutation and iteration are then made and the optimal fitness value and its corresponding process parameters are searched. The optimal fitness value which is predicted theoretically is 98.41, but the actual value is 89.53, and the error is 9.03%. The quality of this verification sample is obviously higher than those of 25 experimental samples. The average slag width is 81.5 μm and the kerf width is 164 μm.

张艺赢, 曹妍, 陈宇翔, 牟向伟. 基于遗传算法的激光切割镍基合金质量优化[J]. 激光与光电子学进展, 2018, 55(11): 111404. Yiying Zhang, Yan Cao, Yuxiang Chen, Xiangwei Mu. Quality Optimization of Laser-Cutted Ni-Based Alloys Based on Genetic Algorithm[J]. Laser & Optoelectronics Progress, 2018, 55(11): 111404.