中国激光, 2019, 46 (3): 0302014, 网络出版: 2019-05-09

激光工艺参数对激光熔化沉积纯钛样品残余应力的影响  下载: 1039次

下载: 1039次

Effects of Laser Process Parameters on Residual Stress of Pure Titanium Samples Prepared by Laser Melting Deposition

激光技术 激光增材制造 小孔法 残余应力 温度梯度 laser technique laser additive manufacturing hole-drilling method residual stress temperature gradient

摘要

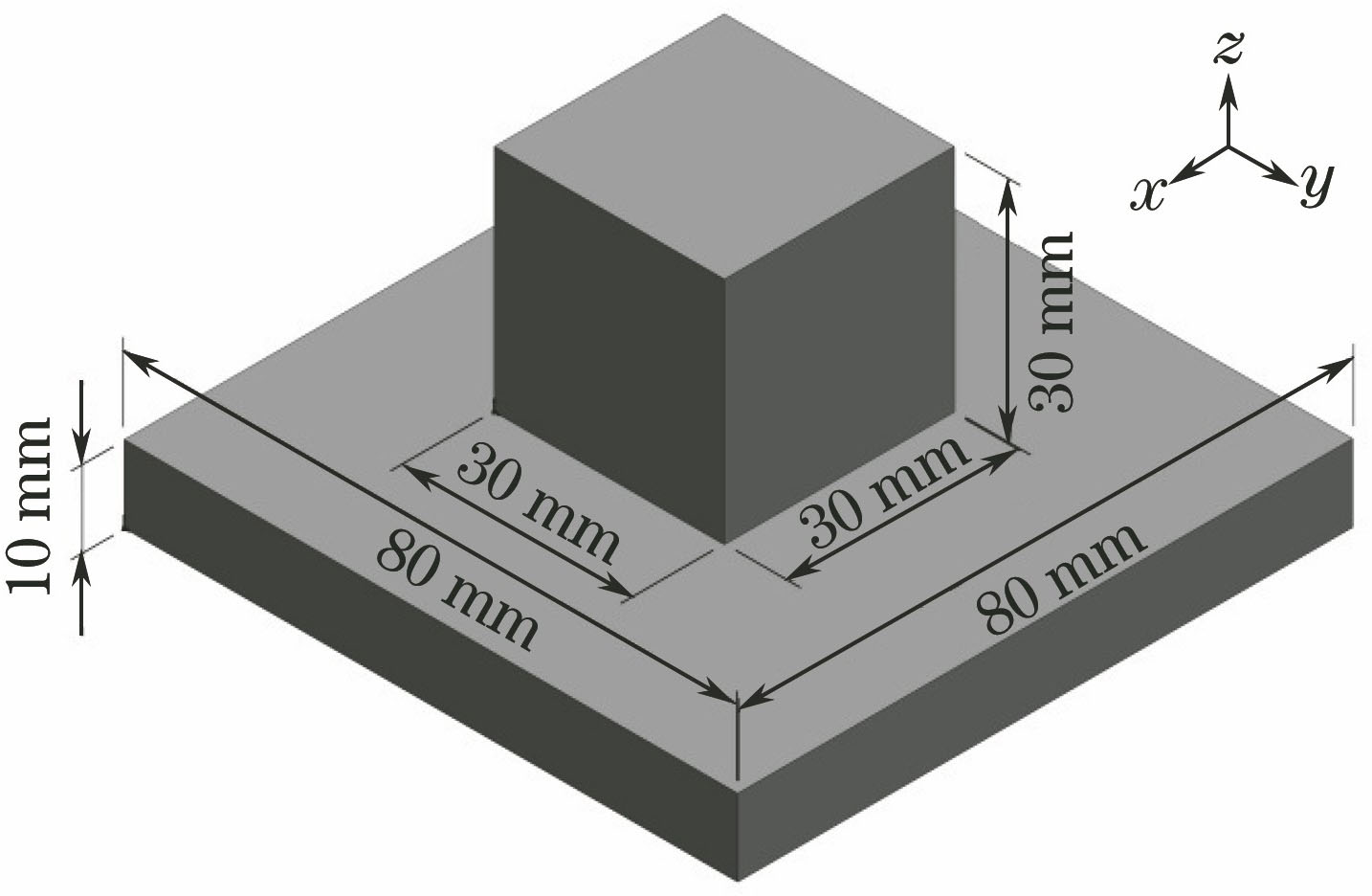

采用同轴送粉激光熔化沉积技术制备了纯钛构件,并利用小孔法对样件扫描面不同部位的残余应力进行了测试,研究了激光功率、扫描速度及送粉率对样件扫描面上残余应力分布的影响。研究结果表明:沉积件与基材结合区为残余压应力区,其他区域为拉应力区,且底部与基材结合区域的残余应力最大,顶部残余应力最小;沉积件底部与基材结合区域的残余应力受激光工艺参数的影响较大,而顶部区域受激光工艺参数的影响较小。通过合理地选取激光工艺参数可有效降低沉积件的残余应力。

Abstract

The pure Ti components are prepared by the laser melting deposition technique with coaxial powder feeding, and the residual stresses in the different regions on the scanning surfaces of samples are measured by the hole-drilling strain method. The effects of laser power, scanning speed and powder feeding rate on the residual stress distributions on the scanning surfaces of samples are also investigated. The research results show that the highest compressive stress appears in the joint area between the deposited component and the substrate and the other areas exhibit the tensile stresses. Moreover, the lowest stress appears at the top area of samples. The residual stress in the joint area between the deposited component and the substrate is strongly dependent on the laser process parameters, while the latter has a slight effect on the residual stress distribution in the top area. The reasonable choice of laser process parameters can effectively reduce the residual stresses of deposited components.

孙洪吉, 韦靖, 郑兆宏, 张德闯, 林建国. 激光工艺参数对激光熔化沉积纯钛样品残余应力的影响[J]. 中国激光, 2019, 46(3): 0302014. Hongji Sun, Jing Wei, Zhaohong Zheng, Dechuang Zhang, Jianguo Lin. Effects of Laser Process Parameters on Residual Stress of Pure Titanium Samples Prepared by Laser Melting Deposition[J]. Chinese Journal of Lasers, 2019, 46(3): 0302014.