中国激光, 2019, 46 (4): 0402007, 网络出版: 2019-05-09

基于机器视觉的铝合金激光清洗实时检测系统  下载: 1183次

下载: 1183次

Machine Vision-Based Real-Time Monitor System for Laser Cleaning Aluminum Alloy

激光技术 激光清洗 机器视觉 实时检测 铝合金 laser technology laser cleaning machine vision real-time monitor aluminum alloy

摘要

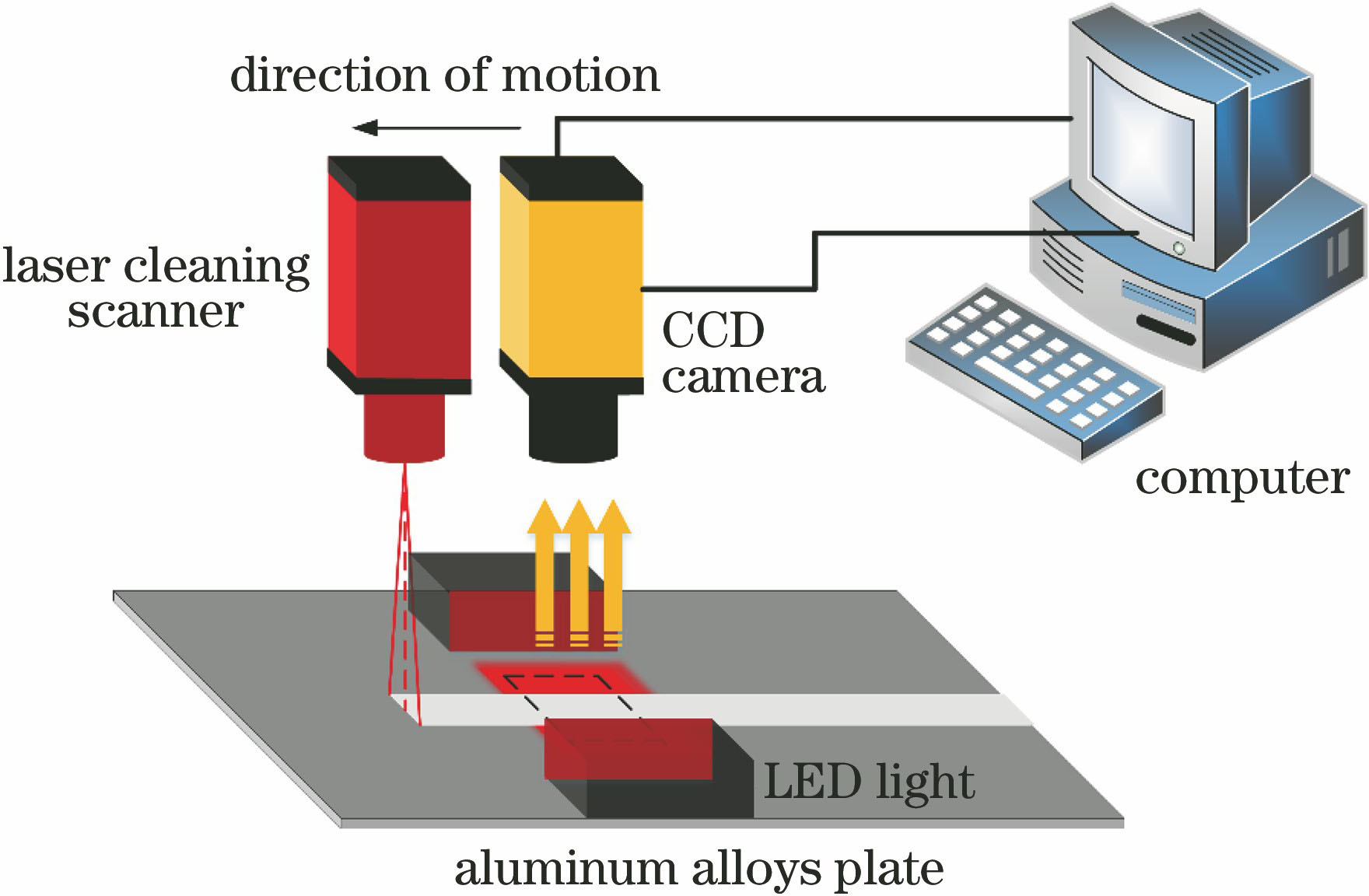

利用高速电耦合器件与发光二极管光源实时获取激光清洗后铝合金的表面图像,设计了铝合金表面氧化膜激光清洗机器视觉在线检测系统,提出了针对激光清洗过程的动态阈值快速定位耦合算法。所提算法解决了激光高速清洗过程中表面光照不均的问题,实现了激光清洗过程中清洗合格区域与不合格区域的准确分割及快速定位。所设计的在线检测系统能够实时检测铝合金表面氧化膜的清洗质量,缩短了检测时间,提高了检测准确度,可以保障整体的清洗质量。

Abstract

Surface images of aluminum alloy after laser cleaning are obtained in real-time with a high speed coupled device and light emitting diode light sources. We design an on-line detection system based on machine vision and propose a dynamic threshold fast position coupling algorithm for laser cleaning aluminum alloy. The proposed algorithm solves the problem of uneven light in laser high-speed cleaning process, realizes the accurate segmentation and the quick positioning of qualified and unqualified areas. The proposed system can detect the quality of the laser cleaning aluminum alloy in real-time. The detection time is reduced, and the recognition accuracy is improved. The system can ensure the cleaning quality.

史天意, 周龙早, 王春明, 米高阳, 蒋平. 基于机器视觉的铝合金激光清洗实时检测系统[J]. 中国激光, 2019, 46(4): 0402007. Tianyi Shi, Longzao Zhou, Chunming Wang, Gaoyang Mi, Ping Jiang. Machine Vision-Based Real-Time Monitor System for Laser Cleaning Aluminum Alloy[J]. Chinese Journal of Lasers, 2019, 46(4): 0402007.