中国激光, 2019, 46 (7): 0702006, 网络出版: 2019-07-11

碳纤维增强热塑性复合材料/铝合金激光搅拌焊接实验及仿真研究  下载: 1258次

下载: 1258次

Experimental and Numerical Studies on Laser Stir Welding of Carbon Fiber Reinforced Thermal Polymers/Aluminum Alloy

激光技术 激光搅拌焊接 碳纤维增强热塑性复合材料 7075铝合金 焊接缺陷 连接强度 laser technique laser stir welding carbon fiber-reinforced thermal polymers 7075 aluminum alloy welding defect jointing strength

摘要

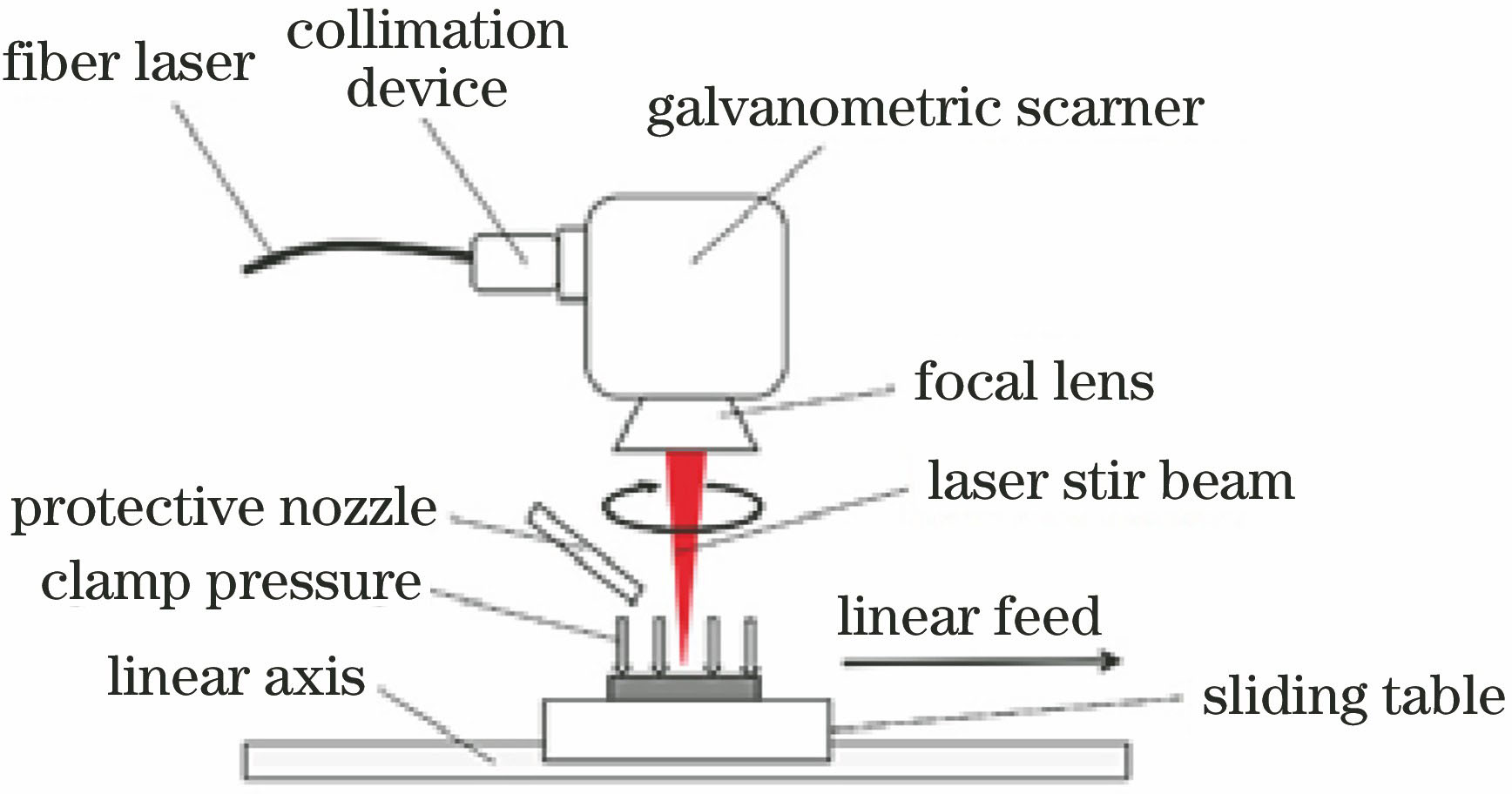

为降低碳纤维增强热塑性复合材料(CFRTP)与铝合金进行激光焊接时,激光加热对铝合金造成的焊接缺陷,提升焊接接头的力学性能,将激光搅拌焊接方法引入到铝合金与CFRTP的焊接中。通过与传统的激光直线焊接方法进行对比后发现:在相同的激光功率和焊接速度下,激光搅拌焊接接头的连接强度为传统激光直线焊接的3.25倍;激光搅拌焊接还可以显著减少气孔缺陷,获得较好的焊缝形貌。为进一步研究CFRTP/铝合金激光搅拌焊接的机理,对CFRTP/铝合金激光搅拌焊接温度场进行仿真分析,结果表明:铝合金表面的温度场呈非等幅振荡形式变化,且出现了两个峰值,这是激光搅拌焊接能够降低焊接缺陷的主要原因之一。同时,对铝合金焊缝的熔深、熔宽进行计算,并与测量结果进行对比,仿真结果与实验结果的误差在9.87%以内。

Abstract

In this paper, we introduce the laser stir welding method to reduce the welding defect of laser heating to aluminum alloy during the laser welding of carbon fiber reinforced thermal polymers (CFRTP)/aluminum alloy and improve the mechanical properties of welded joints during the jointing process. With the same laser power and welding speed, the jointing strength of this method is 3.25 times of that of the traditional linear welding method. Moreover, the bubble defect in laser stir welding is significantly reduced, and a good welding morphology is obtained. Further, the temperature field in the laser stir welding of the CFRTP/aluminum alloy is simulated to study the mechanism of laser stir welding in CFRTP/aluminum alloy. The results show that the temperature on the surface of aluminum alloy changes in the form of a non-equal amplitude oscillation. Two peaks are observed, and laser stir welding can reduce the welding defect owing to these peaks, amongst other reasons. The weld depth and width are calculated, and the error is within 9.87%.

贾少辉, 贾剑平, 焦俊科, 徐子法, 欧阳文泰, 张文武. 碳纤维增强热塑性复合材料/铝合金激光搅拌焊接实验及仿真研究[J]. 中国激光, 2019, 46(7): 0702006. Shaohui Jia, Jianping Jia, Junke Jiao, Zifa Xu, Wentai Ouyang, Wenwu Zhang. Experimental and Numerical Studies on Laser Stir Welding of Carbon Fiber Reinforced Thermal Polymers/Aluminum Alloy[J]. Chinese Journal of Lasers, 2019, 46(7): 0702006.