激光与光电子学进展, 2019, 56 (24): 241405, 网络出版: 2019-11-26

基于ANSYS的TIG电弧增材制造温度场数值模拟分析  下载: 1385次

下载: 1385次

Numerical Simulation of Temperature Field in TIG Arc-Additive Manufacturing Based on ANSYS

激光技术 电弧增材制造 TIG焊接 数值模拟 温度场 模型简化 laser technique arc additive manufacturing TIG weld numerical simulation temperature field model simplification

摘要

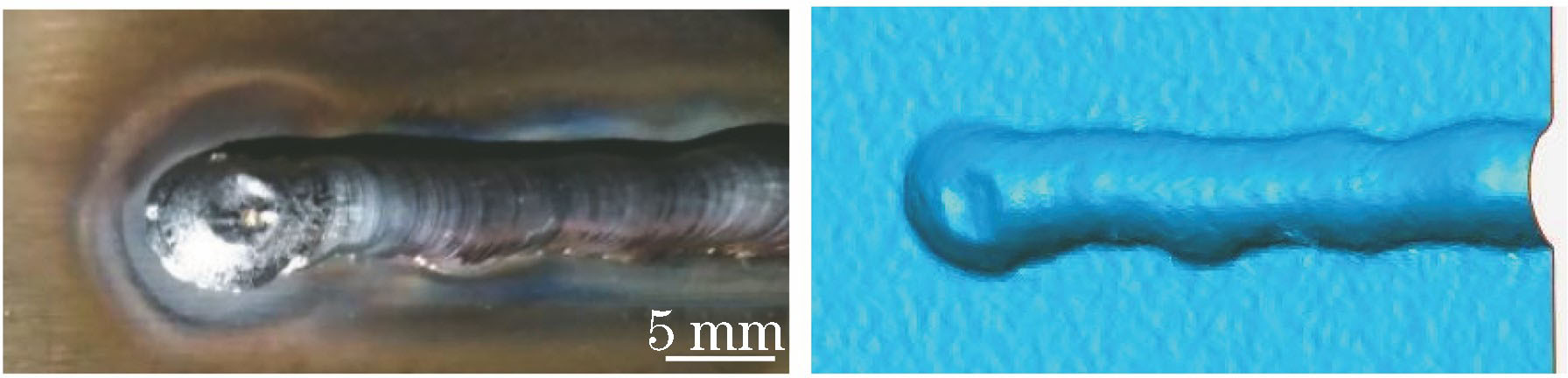

高效率、低成本、制造周期短且无需模具的电弧增材制造技术为大型复杂金属结构件的生产提供了新方法。基于ANSYS参数化设计语言APDL,借助Jmatpro得到了高温下ER50-6碳钢焊丝材料的物理参数,采用生死单元法实现了电弧增材制造过程的动态模拟仿真。模拟分析了单道单层焊接以及焊后冷却过程的温度场分布及温度的变化规律,并与实验结果进行对比,验证了模拟的可行性与正确性。在此基础上分析了不同基板厚度下电弧增材制造温度场的变化规律,得到了增材制造的最佳基板厚度,并研究了直壁零件单道多层增材制造过程中温度场的变化规律。实验得到的焊道温度变化规律可为增材制造后借助堆焊余温对成形件进行锻打改性的时机的选择提供重要的理论依据。

Abstract

Arc additive manufacturing technology with high efficiency, low cost, short manufacturing cycle, and no molds represents a new method for the production of large and complex metal structures. In this study, based on the ANSYS parametric design language APDL, the thermophysical parameters of ER50-6 carbon steel-welding wire are obtained using Jmatpro and the dynamic simulation of arc additive manufacturing process is realized by the birth-death-element method. The feasibility and correctness of the simulation of the temperature variation in welding and post-weld cooling are verified via comparison with the experimental results. The variation rule of the temperature field in arc-additive manufacturing under different substrate thicknesses is analyzed to obtain optimal substrate thickness. Furthermore, the study explores the variation of the temperature field during the multi-layer additive manufacturing process of straight, single wall parts. This provides an important theoretical basis for forging modification process of the formed parts based on additive manufacturing residual temperature.

刘东帅, 吕彦明, 周文军, 杨华, 王康. 基于ANSYS的TIG电弧增材制造温度场数值模拟分析[J]. 激光与光电子学进展, 2019, 56(24): 241405. Dongshuai Liu, Yanming Lü, Wenjun Zhou, Hua Yang, Kang Wang. Numerical Simulation of Temperature Field in TIG Arc-Additive Manufacturing Based on ANSYS[J]. Laser & Optoelectronics Progress, 2019, 56(24): 241405.