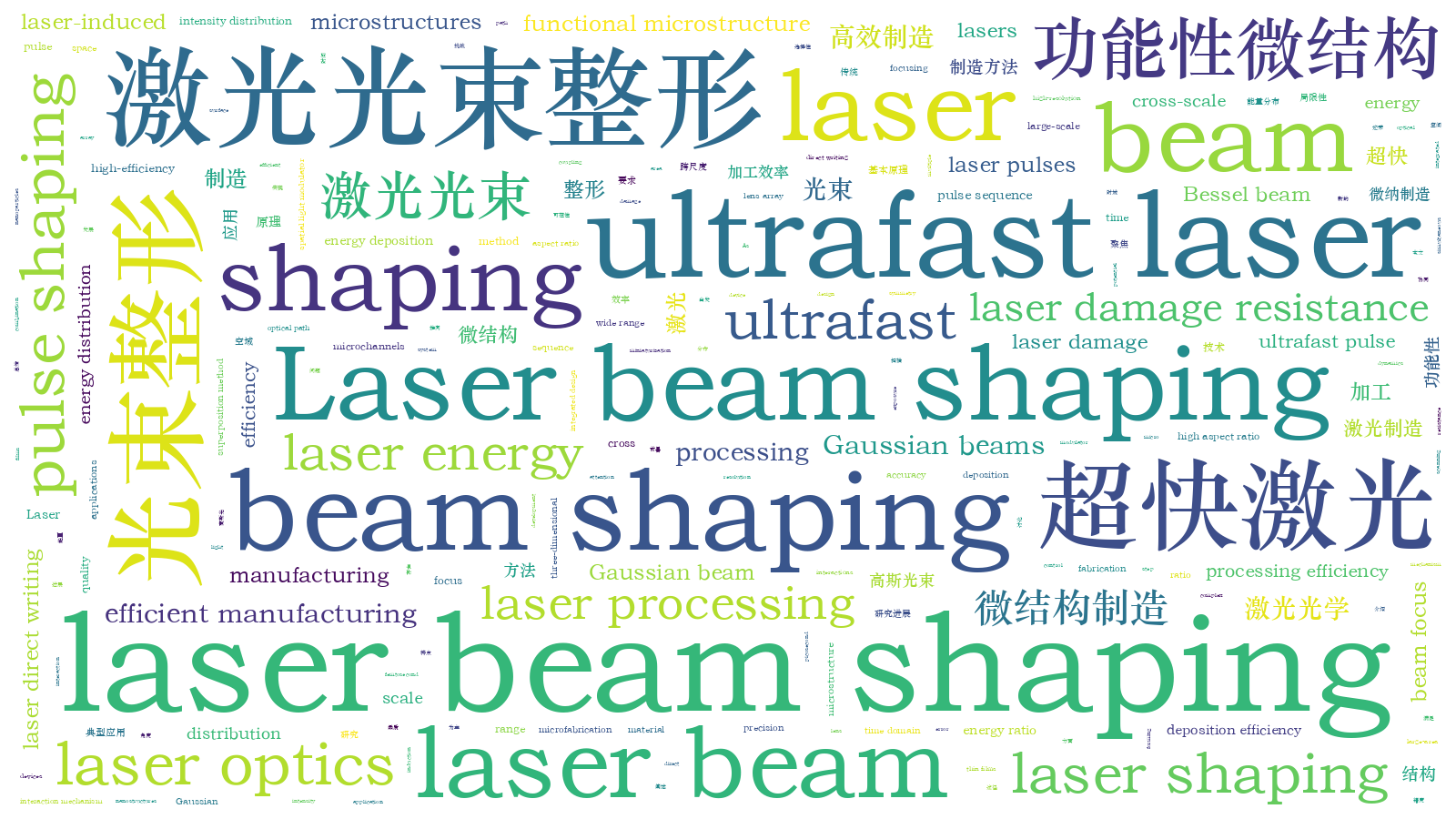

超快激光光束整形原理与方法及其在功能性微结构制造中的应用  下载: 2559次特邀综述

下载: 2559次特邀综述

Significance As manufacturing quality requirements for functional microstructures increase, ultrafast laser micro/nanomanufacturing has brought new challenges related to high processing efficiency, cross-scale processing, and selective or controllable processing, etc. The limitations of the spatial and temporal energy distribution of traditional ultrafast laser Gaussian beams and processing methods based on single-point focus scanning make it difficult to meet the latest manufacturing accuracy, efficiency, and cross-scale processing requirements. Therefore, researchers focus their attention on manufacturing methods based on ultrafast laser beam shaping.

Progress Laser beam shaping can be divided into two types: spatial beam shaping and temporal beam shaping. Spatial beam shaping refers to tailoring the distribution of laser energy in the space domain, whereas, temporal beam shaping refers to changing the distribution of laser energy in the time domain. Compared with a traditional Gaussian beam, a shaped beam has new spatial and temporal energy distribution, which can meet the manufacturing requirements of specific structures or applications.

By shaping the spatial profile of an ultrafast laser beam, the fabrication of microstructures with various shapes can be directly realized on exposure to single or multiple laser pulses. Common laser shaping methods include the spatial light modulator method (Figs. 1--3), lens array method (

Temporal beam shaping transforms a conventional ultrafast pulse into a pulse sequence (Figs. 8 and 9). Each pulse sequence contains several subpulses with a time interval from a femtosecond to a picosecond range. The energy ratio between each subpulse can be derived. Temporal beam shaping can control electronic dynamics during laser-material interactions, which has a wide range of applications in the manufacturing of microchannels (

To further improve the quality and efficiency of ultrafast laser processing, it is necessary to perform the coordinated shaping of ultrafast lasers in the time and space domains. On the one hand, spatial and temporal beam shaping can be performed separately in one optical path by combining double pulses and a Bessel beam (

Conclusion and Prospect The ultrafast laser beam shaping technology has the potential to greatly improve the variety, precision, and efficiency of functional microstructure manufacturing. A combination of the ultrafast laser beam shaping technology and microfabrication promotes the efficient and controllable manufacturing of large-area, high-quality functional microstructures, which accelerates the development of commercial scale-forming devices based on the microstructures. However, there are still some challenges with the ultrafast laser beam shaping technology. For example, the laser damage resistance of a shaping device weakens its processing ability, error of the complex shaping system affects its processing accuracy, and interaction mechanism between the shaped ultrafast laser beam and material to be processed is not fully known. These problems and challenges need to be overcome in the future. Facing the need for the miniaturization, integrated design, and large-scale manufacturing of functional microdevices, the ultrafast laser beam shaping manufacturing technology can be highly suitable for high-resolution, cross-scale, three-dimensional, and high-efficiency processing.

丁铠文, 王聪, 罗志, 梁会勇, 段吉安. 超快激光光束整形原理与方法及其在功能性微结构制造中的应用[J]. 中国激光, 2021, 48(2): 0202005. Kaiwen Ding, Cong Wang, Zhi Luo, Huiyong Liang, Ji’an Duan. Principle and Method of Ultrafast Laser Beam Shaping and Its Application in Functional Microstructure Fabrication[J]. Chinese Journal of Lasers, 2021, 48(2): 0202005.