激光与光电子学进展, 2020, 57 (13): 131404, 网络出版: 2020-07-09

工艺参数对哈氏合金薄板激光填丝焊接变形的影响  下载: 935次

下载: 935次

Effect of Parameters on Welding Deformation of Laser Welding Hastelloy Thin Sheets with Filler Wire

激光光学 激光填丝焊接 哈氏合金 挠曲变形 弯曲刚度 线能量 laser optics laser welding with filler wire Hastelloy flexure deformation bending stiffness linear heat input

摘要

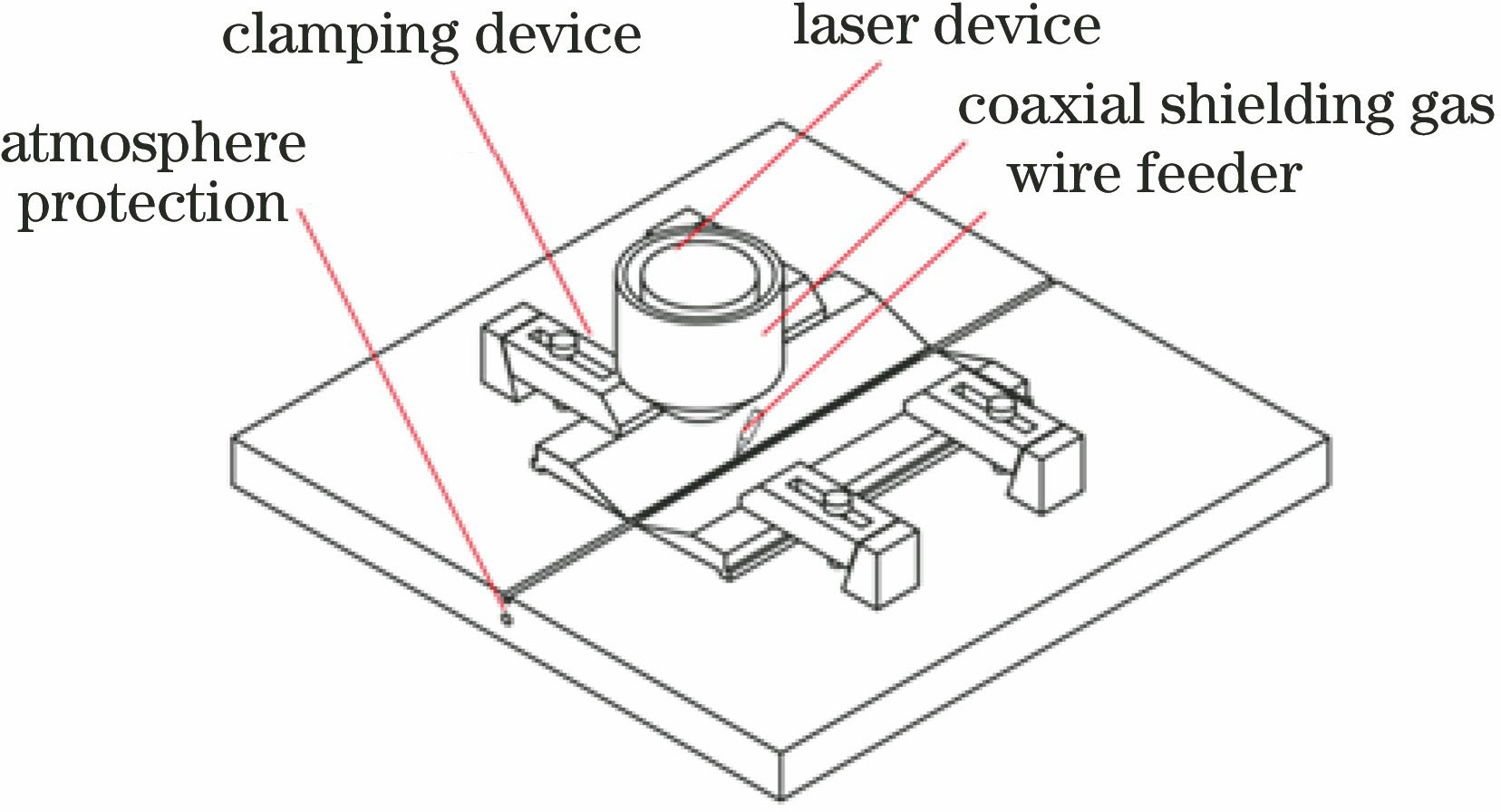

研究了激光填丝焊接工艺参数对哈氏合金薄板纵向挠曲变形的影响,结合样件弯曲刚度和等效载荷分析了焊接工艺参数对纵向挠曲变形的影响。结果表明:激光填丝焊接过程的线能量和相对送丝量通过影响弯曲刚度和等效载荷,进而影响纵向挠曲变形;随着线能量的逐渐增大,等效载荷也逐渐增大,样件的弯曲刚度呈减小—增大—减小的变化趋势。在一定范围内增大线能量会使等效载荷和弯曲刚度同时增大,从而导致挠曲变形的变化幅度相对较小。相对送丝量增大使弯曲刚度在等效载荷不变的情况下明显增大,从而导致焊接变形减小。在合理的参数范围内尽量选择小线能量和大相对送丝量有利于抑制变形。

Abstract

Herein, the effect of parameters on the longitudinal flexure deformation in laser welding Hastelloy C-276 using the filler wire process is evaluated by combining bending stiffness and load analyses. Results show that the linear heat input and relative wire speed can affect the longitudinal flexure deformation through the bending stiffness and equivalent load. As the linear heat input increases, the equivalent load also gradually increases, and the bending stiffness shows a decreasing→increasing→decreasing trend. Moreover, the equivalent load and bending stiffness will simultaneously increase when the linear heat input increases in a certain range, resulting in a relatively small change in flexure deformation. By increasing the relative wire speed, the bending stiffness of sample is improved, thereby causing a significant reduction in the welding deformation. By selecting small linear heat input and large relative wire speed within reasonable parameters, welding deformation can be restrained.

吴东江, 刘俊, 唐博凯, 刘德华, 马广义, 牛方勇, 姚振强. 工艺参数对哈氏合金薄板激光填丝焊接变形的影响[J]. 激光与光电子学进展, 2020, 57(13): 131404. Dongjiang Wu, Jun Liu, Bokai Tang, Dehua Liu, Guangyi Ma, Fangyong Niu, Zhenqiang Yao. Effect of Parameters on Welding Deformation of Laser Welding Hastelloy Thin Sheets with Filler Wire[J]. Laser & Optoelectronics Progress, 2020, 57(13): 131404.