激光与光电子学进展, 2019, 56 (21): 211403, 网络出版: 2019-11-09

基于激光清洗的AH32钢的电化学腐蚀性能  下载: 1051次

下载: 1051次

Electrochemical Corrosion Properties of AH32 Steel via Laser Cleaning

激光光学 激光清洗 AH32钢 极化曲线 电化学阻抗谱 表面形貌 laser optics laser cleaning AH32 steel polarization curve electrochemical impedance spectroscopy surface morphology

摘要

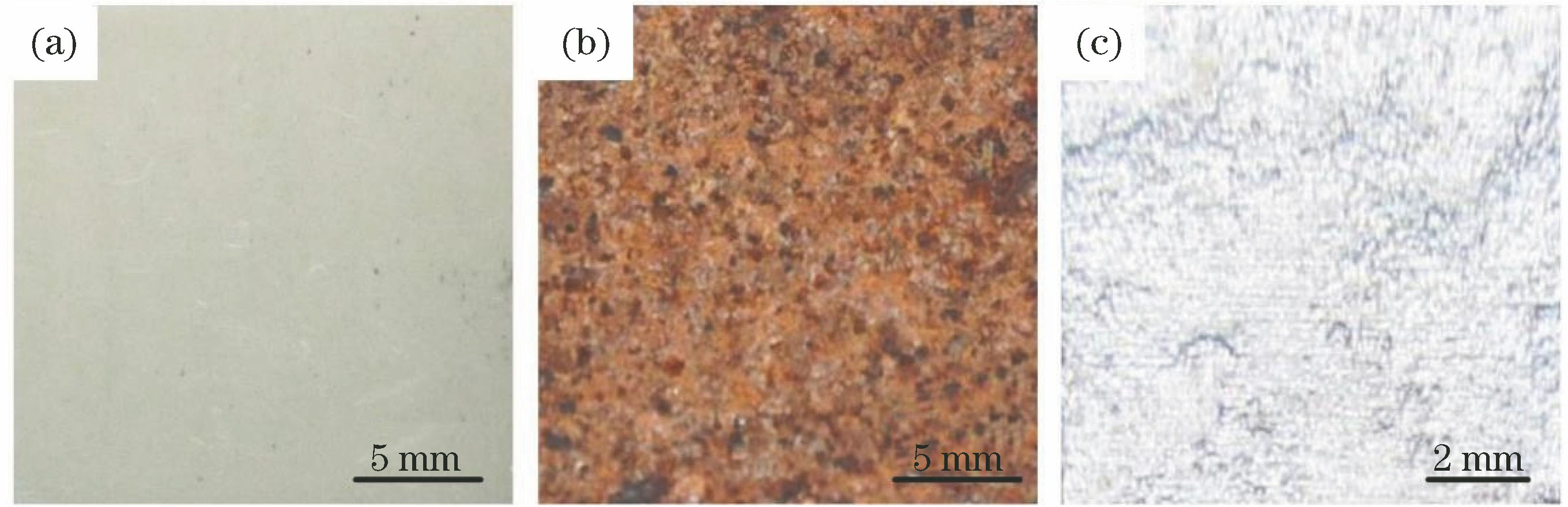

为研究激光清洗对钢铁耐蚀性的影响,采用电化学方法研究激光清洗的AH32钢在3.5%(质量分数)NaCl溶液中的电化学腐蚀行为,并对试样的极化曲线、电化学阻抗谱和表面形貌进行测试与分析。结果表明:激光清洗改善了AH32钢的耐蚀性;在材料的损伤阈值内,随着激光能量密度和光斑搭接率增大,AH32钢的自腐蚀电位正向移动,腐蚀电流密度降低,阻抗弧变大,耐蚀性增加;当激光能量密度为20 J/cm 2、光斑搭接率为50%时,AH32钢的耐蚀性最佳。该结果可为研究纳秒脉冲激光清洗后材料的表面性能提供参考依据。

Abstract

The electrochemical corrosion behavior of laser-cleaned AH32 steel in 3.5% (mass fraction) NaCl solution was studied herein through the electrochemical method to investigate the effect of laser cleaning (LC) on the corrosion resistance of steel. The polarization curve, electrochemical impedance spectroscopy, and surface morphology of the sample were tested and analyzed. Results show that the corrosion resistance of AH32 steel is improved post LC. Within the material damage threshold, the self-corrosion potential of AH32 steel moves in a positive direction with increasing laser energy density and spot overlap rate; simultaneously, the corrosion current density decreases, and the impedance arc becomes larger, thereby the corrosion resistance increases. The corrosion resistance of AH32 steel is the best when the laser energy density is 20 J/cm 2, and the spot overlap ratio is 50%. These results can provide a reference for studying surface properties post nanosecond pulse LC.

李华婷, 周建忠, 孙奇, 高辽远, 朱明, 郭召恒, 杨嘉年, 付强. 基于激光清洗的AH32钢的电化学腐蚀性能[J]. 激光与光电子学进展, 2019, 56(21): 211403. Huating Li, Jianzhong Zhou, Qi Sun, Liaoyuan Gao, Ming Zhu, Zhaoheng Guo, Jianian Yang, Qiang Fu. Electrochemical Corrosion Properties of AH32 Steel via Laser Cleaning[J]. Laser & Optoelectronics Progress, 2019, 56(21): 211403.