激光与光电子学进展, 2020, 57 (5): 052204, 网络出版: 2020-03-05

衍射微透镜注塑成型工艺参数优化及误差补偿  下载: 957次

下载: 957次

Parameter Optimization and Error Compensation of Diffraction Microlens Injection Molding Process

光学设计 衍射微结构 注塑成型 正交实验 多目标优化 误差补偿 optical design diffraction microstructure injection molding orthogonal experiment multi-objective optimization error compensation

摘要

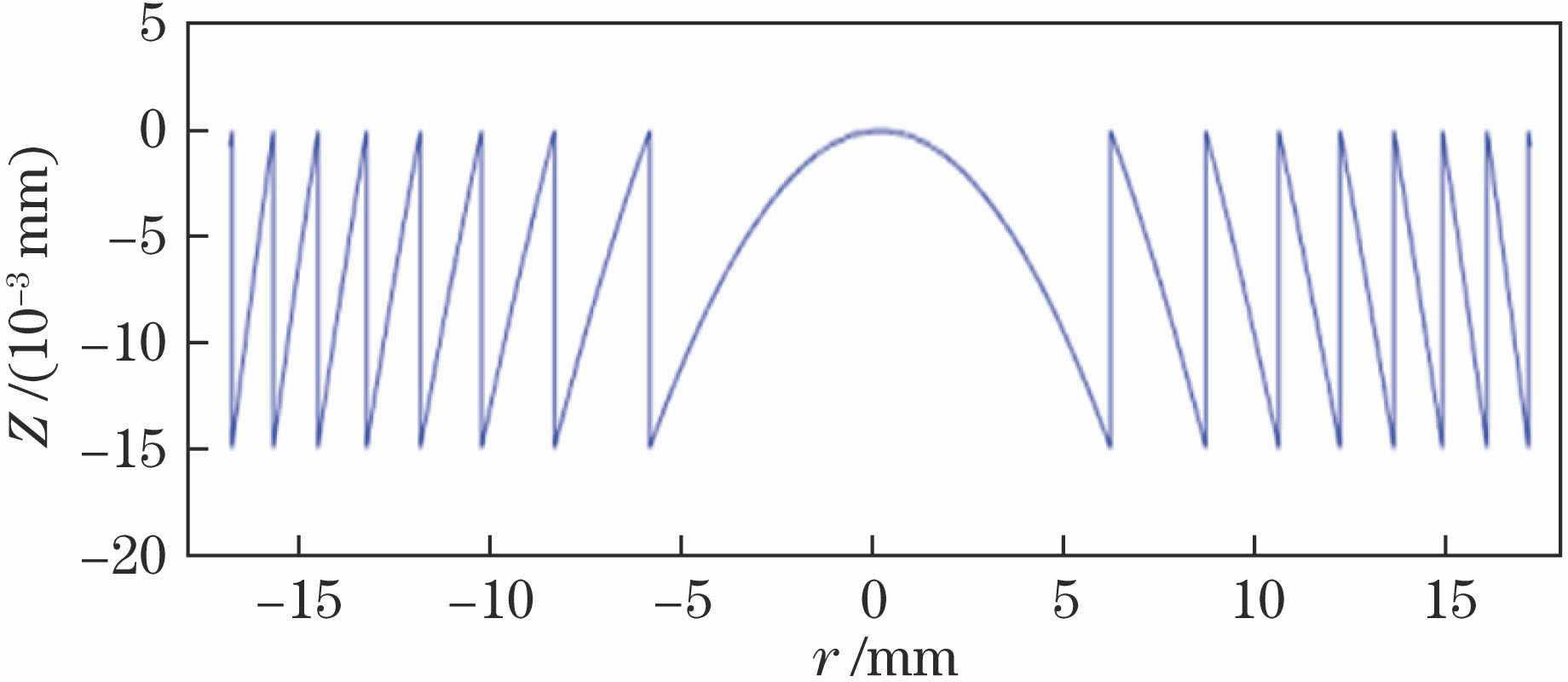

为了制造高精度塑料衍射微透镜,提出采用Taguchi方法在大范围内选择工艺参数,通过信噪比确定显著影响微结构成型精度的工艺参数,并通过加权综合评分法进行多目标优化获得最优参数组合。结果表明保压压力、模具温度和保压时间对微结构成型精度具有显著影响。为了提高衍射微结构成型精度,分析了衍射微透镜注塑成型误差的主要来源并建立了误差补偿模型。实验结果表明注塑成型的衍射微结构高度误差为5.69%,周期宽度误差为6.16%,衍射微结构的注塑成型精度获得显著提高。

Abstract

In order to manufacture high-precision plastic diffraction microlenses, this paper proposes to select the process parameters in a wide range by Taguchi method, determine the process parameters that significantly affect the molding precision of microstructure through the signal-to-noise ratio, and obtain the optimal parameter combination through multi-objective optimization by weighted comprehensive scoring method. The results show that the holding pressure, mold temperature, and holding time have a significant impact on the microstructure molding precision. In order to improve the precision of diffraction microstructure, the main source of diffraction microlens injection molding error is analyzed and the error compensation model is established. The experimental results show that the diffraction microstructure of the injection molding has a height error of 5.69% and a period error of 6.16%, and the injection molding precision of the diffraction microstructure is significantly improved.

刘兴国, 霍富荣, 薛常喜. 衍射微透镜注塑成型工艺参数优化及误差补偿[J]. 激光与光电子学进展, 2020, 57(5): 052204. Xingguo Liu, Furong Huo, Changxi Xue. Parameter Optimization and Error Compensation of Diffraction Microlens Injection Molding Process[J]. Laser & Optoelectronics Progress, 2020, 57(5): 052204.