超疏水聚偏氟乙烯的激光加工  下载: 1516次特邀综述

下载: 1516次特邀综述

Objective Various bioinspired surfaces about super-wettability have been widely investigated. For example, water droplets move freely on the lotus leaf surface, in an anisotropic way on rice leaf surfaces, and unidirectionally on pitcher surfaces. With the progress of science and technology, the mechanisms for these bioinspired surfaces have been revealed. Importantly, bioinspired surfaces have abroad applications in biological, industrial, micromechanical, and other fields. For example, superhydrophobic surfaces, requiring high roughness and low surface energy, show self-cleaning and anti-icing characteristics. From the view of materials, organic polymer materials have lower surface energy than other materials, showing great potential in developing superhydrophobic surfaces. As a typical polymer material, polyvinylidene fluoride (PVDF) shows excellent flexibility, chemical corrosion resistance, and piezoelectricity. Superhydrophobic PVDF has recently been prepared by various methods, such as hybrid modification and surface chemistry modification. However, these methods require special chemical reagents or complicated equipment. Herein, we designed and fabricated PVDF-based membranes with superhydrophobicity by laser processing technology. After the laser treatment, the laser treated-PVDF (L-PVDF) surface owns microstructures and low surface energy. Therefore, the L-PVDF surface shows superhydrophobicity. This work provides a new method to prepare the PVDF membrane with excellent superhydrophobicity.

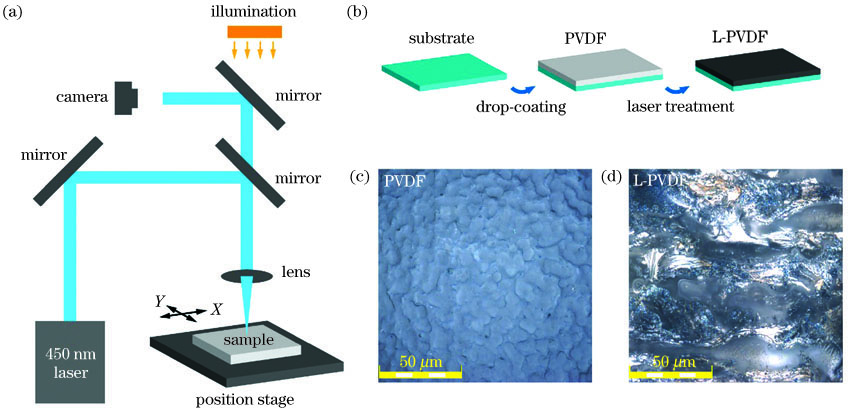

Methods powders and N, N—dimethylformamide (DMF) solvent are mixed in the ratio of 1 g∶8ml. After ultrasonic treatment for 1h, the PVDF powder is uniformly dispersed. The PVDF@DMF solution is drop-coated on substrates to fabricate PVDF membranes. As for the preparation of L-PVDF surfaces, a continuous semiconductor laser wavelength (λ=450nm, power P=1200mW) is used. After the laser treatment, the L-PVDF surface shows superhydrophobic characteristc. The morphologies of lotus leaf, PVDF, and L-PVDF surfaces are measured by a confocal laser scanning microscope (CLSM) and a scanning electron microscope (SEM). The chemical compositions of the PVDF and L-PVDF are analyzed by X-ray photoelectron spectroscopy (XPS). The surface wettability and wettability stability of the PVDF and L-PVDF are characterized by a static contact angle (CA) measuring system. For the CA measurement, the area of laser treatment is 10mm×10mm, and the processing time is about 3min.

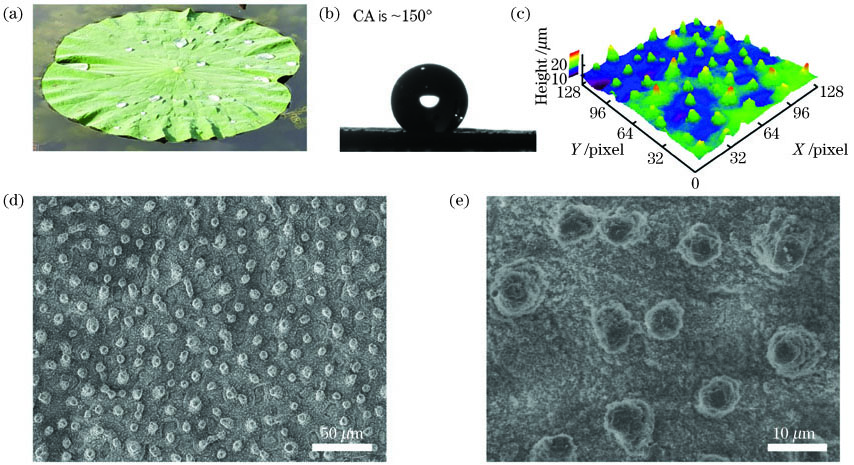

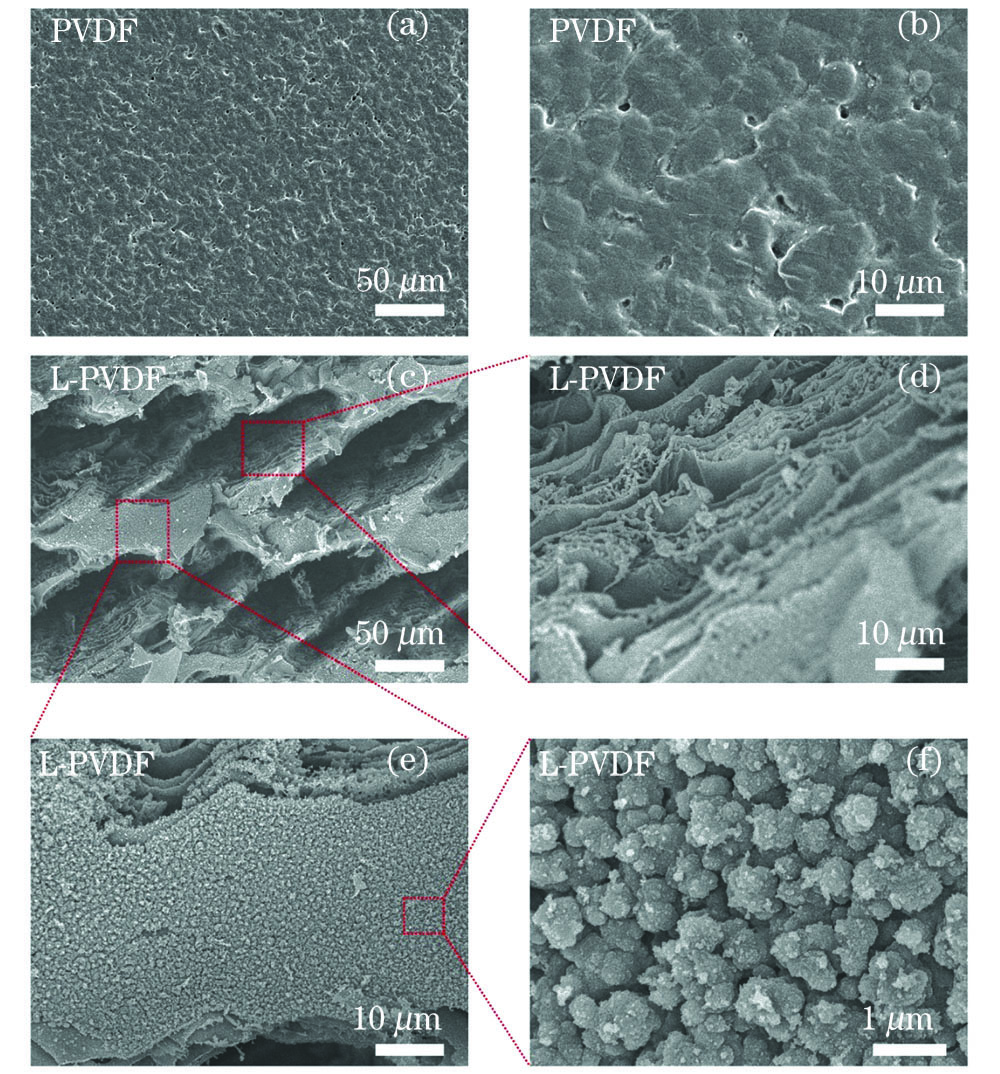

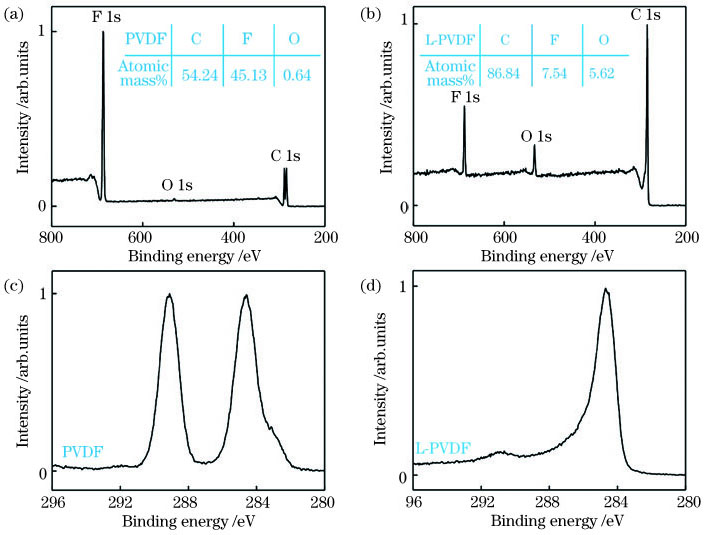

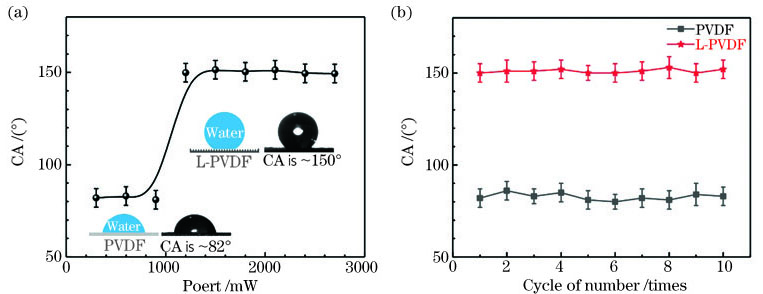

Results and Discussion The static CA of water drops on a lotus leaf is ~150°, indicating superhydrophobic characteristic. To explore the mechanism of the superhydrophobic characteristic of water droplets on the lotus leaf surface, we characterized the lotus leaf surface morphology by the CLSM and SEM, respectively. There are microscaled papillae with a diameter of 3--5μm and a height of 5--10μm (Fig. 1). The existence of microscaled papillae can effectively reduce the contact area between water droplets and lotus leaf surfaces, leading to the superhydrophobic effect. Fig. 2 shows the laser processing system and the procedure of laser processing PVDF surface. The SEM images show that there are grooves along the laser scanning path. The distance between grooves is ~100μm, and the width is ~70μm. Moreover, many particles (diameter is ~ 1μm) are observed. The size and shape of particles are similar to the papillae on a lotus leaf (Fig. 3). Besides, XPS is performed to investigate the change of surface composition of PVDF and L-PVDF surface. The C/F atom ratio has significantly changed from 1.2 (PVDF) to 11.5 (L-PVDF), which indicates that the molecular chain of PVDF is destroyed by high laser power, and defluorination may occur (Fig. 4). Compared with the CA of PVDF film (~ 82°), the L-PVDF surface shows hydrophobicity with a CA of ~ 150°(Fig. 5).

Conclusions Inspired by the microstructures on the lotus leaf surfaces, a L-PVDF-based superhydrophobic surface has been prepared by a continuous semiconductor laser (λ=450nm, P=1200mW). CLSM and SEM are used to characterize the microstructure of L-PVDF. Grooves and microscaled papillae are induced fabrication by the laser thermal effect. The microstructures on the surface of L-PVDF is similar to that of the lotus leaf surface. Besides, the rough structure reduces the contact area between water droplets and the L-PVDF surface. XPS reveals that the C/F atom ratio on the surface increased from 1.2 (PVDF) to 11.5 (L-PVDF). Therefore, the CA of L-PVDF is mainly dependent on the change of microstructures and composition. The static CA on the L-PVDF surface is ~150°. This work shows the fabrication of superhydrophobic L-PVDF films by laser processing. The laser processing is simple and does not involve chemical reagents. We deem that this method provides a new strategy to prepare a PVDF-based superhydrophobic surface.

1 引言

自然界中存在着各种各样的奇妙现象,如水滴在荷叶表面自由滚动、水滴在水稻叶表面各向异性滚动、水滴在猪笼草口缘区单向运动现象[1-2]。随着科学技术的发展,近年来对特异浸润性表面的研究也受到了人们的关注,并在日常生活、工业生产等领域产生了巨大的经济价值。如超疏水表面具有自清洁性、抗结冰性等特点,已被广泛应用于生物、工业、微机械等领域[3]。

固体表面的超疏水性质通常与表面微纳结构和化学组分有关[4-7]。一方面,表面微纳结构可以减小水滴与固体表面的接触面积,提高疏水性能,常用模板法、光刻、电镀、自组装、化学腐蚀等工艺在固体表面引入微纳结构。另一方面,通过化学试剂改变材料表面的化学组分,可降低材料表面能,提高疏水性能。从制备方法角度来看,激光加工技术具有易于控制、精度高等优点[8-10],被广泛应用于多种结构和器件的制备[11-17]。且激光加工技术具有良好的适用性[18-21],不论是硬质材料还是柔性材料,都可以通过调控激光加工参数制备特定微纳结构和表面改性[22-25]。

有机材料的表面能较低,因此超疏水有机材料的制备成为超疏水领域研究的热点。如Yuan等[26]以芋头叶为模板,制备出具有与天然芋头叶乳突类似的聚苯乙烯膜,表面的水滴接触角为158°±1.6°;Oktay等[27]通过静电纺丝技术制备出基于聚酰亚胺硅氧烷复合材料的电纺薄膜,薄膜表面显示出与荷叶相似的超疏水性,可作为自清洁薄膜;Gong等[28]创新性地将聚二甲硅氧烷(PDMS)倒入激光烧蚀出的不锈钢板中固化,得到静态接触角可达155°的超疏水PDMS薄膜;Wang等[29]用激光直接处理PDMS表面,使PDMS发生碳化,碳化后的表面具有超疏水性。

聚偏氟乙烯(PVDF)是一种常见的有机高分子共聚物,具有良好的柔性、耐腐蚀性、压电性等优点[30]。迄今为止,共混改性、表面处理改性等方式已被用于制备基于PVDF的超疏水表面,但通常需要特殊的化学试剂或复杂的工艺设备[31-34]。针对上述问题,本文提出以激光加工技术为基础,仿荷叶的超疏水表面对PVDF薄膜进行加工,实现了具有微结构、低表面能的超疏水聚偏氟乙烯,处理过程简便且不涉及化学试剂。

2 实验部分

2.1 实验材料及设备

PVDF粉末材料购买于Sigma-Aldrich公司,N,N—二甲基甲酰胺(DMF)购买于上海阿拉丁生化科技股份有限公司,用于PVDF粉末的溶解及成膜。激光器为半导体连续激光器,波长为450nm,焦距为50mm,光斑直径约为70μm,采用单向线扫描方式,扫描速度为3mm/s,最大输出功率为3000mW。研究不同激光功率处理PVDF表面对疏水性能的影响时,采用不用激光功率(300,600,900,1200,1500,1800,2100,2400,2700mW)对薄膜表面进行激光处理,得到激光处理过的PVDF薄膜材料(L-PVDF)。激光处理的面积为10mm×10mm,加工时间约为3min,用于静态接触角(CA)测试。用静态接触角测试仪(SDC-350,SIN DIN Corporation)测量薄膜材料表面的水滴静态接触角,液体体积为6 μL。采用激光共聚焦显微镜(CLSM,OLS4100)、冷场发射扫描电子显微镜(SEM,JSM-7500)对表面结构进行观察,用X射线光电子能谱(XPS,ESCALAB 250 spectrometer)测试样品表面元素的变化情况。

2.2 PVDF薄膜以及超疏水PVDF薄膜的制备

将PVDF粉末与DMF溶剂按照1 g∶8mL的比例进行混合,搅拌至粉末溶于液体后,放置于超声清洗机中进行超声处理(1h),使PVDF粉末分散更均匀,同时去除混合过程中引入的气泡,得到流动性、成膜性较好的均匀混合物。

将混合物滴在玻璃基底上,混合物在温度为80 ℃时热烘干处理10~15min后成膜。通过SEM观察,制备的PVDF薄膜厚度约为17μm。将PVDF薄膜放置于半导体连续激光器的加工区域,在合适的功率下对薄膜表面进行激光处理,得到L-PVDF材料,加工区域的大小根据需求面积设置。同时对未加工的PVDF薄膜也进行裁剪,得到相同面积(10mm×10mm)的PVDF薄膜材料,用于实验测试、对比分析。

3 分析与讨论

3.1 荷叶表面形貌观察

如

图 1. 荷叶疏水性能的测试。(a)实物图;(b)静态接触角;(c) CLSM图像;(d) SEM图像(50μm);(e) SEM图像(10μm)

Fig. 1. Test of the hydrophobicity of lotus leaf. (a) Photograph; (b) static contact angle; (c) CLSM image; (d) SEM image (50μm); (e) SEM image (10μm)

3.2 PVDF与L-PVDF表面形貌对比

图 2. PVDF的激光加工处理。(a)激光加工系统;(b)激光处理PVDF的示意图;(c)PVDF薄膜的表面;(d)L-PVDF薄膜表面

Fig. 2. Laser processing of PVDF. (a) Laser processing system; (b) schematic diagram of laser processing PVDF; (c) surface of PVDF film; (d) surface of L-PVDF film

用SEM对PVDF和L-PVDF薄膜表面结构进行观察分析,结果如

图 3. PVDF及L-PVDF薄膜表面的SEM图像。 (a)~(b) PVDF薄膜;(c)~(f) L-PVDF薄膜

Fig. 3. SEM images of the surface of PVDF and L-PVDF films. (a)--(b) PVDF films; (c)--(f) L-PVDF films

3.3 PVDF与L-PVDF的成分对比

材料表面的浸润性主要由微纳结构和化学组分两部分决定。为了详细分析经激光处理前后PVDF的表面组分变化,分别对PVDF和L-PVDF进行XPS测试。PVDF薄膜表面的碳元素含量(原子数分数)约为52.27%,氟元素含量约为47.24%,碳元素与氟元素含量的比值为1.2,如

图 4. PVDF的XPS谱图。(a) PVDF薄膜;(b) L-PVDF薄膜表面的XPS宽谱图;(c) PVDF薄膜;(d) L-PVDF薄膜表面的C1s谱图

Fig. 4. XPS spectrum of PVDF. (a) PVDF film; (b) XPS broad spectrum of L-PVDF film surface; (c) PVDF film; (d) C1s spectrum of L-PVDF film surface

3.4 PVDF与L-PVDF表面疏水性能的对比

图 5. 静态接触角的测试。(a)不同加工功率下的表面静态接触角;(b) 表面静态接触角的稳定性测试

Fig. 5. Test of the static contact angle. (a) Surface static contact angle under different processing power; (b) stability test of the surface static contact angle

4 结论

受荷叶微观表面的启发,用波长为450nm的半导体连续激光对PVDF表面进行加工,结果表明,L-PVDF表面的水滴静态接触角可达到150°,具有很好的超疏水性质。同时连续对L-PVDF进行静态接触角测试,结果都稳定在150°附近,具有很好的稳定性。通过CLSM和SEM对薄膜的微观结构进行表征,结果表明,激光扫描路径形成的沟槽以及激光热效应形成的微小颗粒状结构使L-PVDF表面具有与荷叶表面类似的粗糙结构,这种结构减小了水滴与表面的接触面积。结合XPS分析得到的结果表明,激光处理前后,材料表面碳元素与氟元素含量的比值由1.2提高至11.5。采用激光加工制备PVDF超疏水表面的方法高效便捷,处理过程简便且不涉及化学试剂,为制备PVDF超疏水表面提供了新思路。

[1] 龙江游, 范培迅, 龚鼎为, 等. 超快激光制备具有特殊浸润性的仿生表面[J]. 中国激光, 2016, 43(8): 0800001.

[2] Liu M J, Wang S T, Jiang L. Nature-inspired superwettability systems[J]. Nature Reviews Materials, 2017, 2: 17036.

[3] 张径舟, 陈烽, 雍佳乐, 等. 飞秒激光诱导仿生超疏水材料表面的研究进展[J]. 激光与光电子学进展, 2018, 55(11): 110001.

[4] Wang S, Liu K, Yao X, et al. Bioinspired surfaces with superwettability:new insight on theory, design, and applications[J]. Chemical Reviews, 2015, 115(16): 8230-8293.

[5] Han D D, Zhang Y L, Jiang H B, et al. Moisture-responsive graphene paper prepared by self-controlled photoreduction[J]. Advanced Materials, 2015, 27(2): 332-338.

[6] Wang L, Chen Q D, Cao X W, et al. Plasmonic nano-printing:large-area nanoscale energy deposition for efficient surface texturing[J]. Light: Science & Applications, 2017, 6(12): e17112.

[7] Yang J, Luo F F, Kao T S, et al. Design and fabrication of broadband ultralow reflectivity black Si surfaces by laser micro/nanoprocessing[J]. Light: Science & Applications, 2014, 3(7): e185.

[8] Sugioka K, Cheng Y. Ultrafast lasers-reliable tools for advanced materials processing[J]. Light: Science & Applications, 2014, 3(4): e149.

[10] 史杨, 许兵, 吴东, 等. 飞秒激光直写技术制备功能化微流控芯片研究进展[J]. 中国激光, 2019, 46(10): 1000001.

[11] Wu D, Xu J, Niu L G, et al. In-channel integration of designable microoptical devices using flat scaffold-supported femtosecond-laser microfabrication for coupling-free optofluidic cell counting[J]. Light: Science & Applications, 2015, 4(1): e228.

[12] Han D D, Zhang Y L, Ma J N, et al. Light-mediated manufacture and manipulation of actuators[J]. Advanced Materials, 2016, 28(38): 8328-8343.

[13] Zhang Y L, Liu Y Q, Han D D, et al. Quantum-confined-superfluidics-enabled moisture actuation based on unilaterally structured graphene oxide papers[J]. Advanced Materials, 2019, 31(32): 1901585.

[14] Fu XY, Chen ZD, Han DD, et al. Laser fabrication of graphene-based supercapacitors[J]. Photonics Research, 2020( 4): 577- 588.

[16] 韩冬冬, 蔡青, 李纪超, 等. 激光诱导石墨烯水下超疏油仿生表面的制备[J]. 激光与光电子学进展, 2020, 57(15): 151408.

[17] 姜源, 江毅, 张柳超, 等. 基于飞秒激光加工的无膜光纤气体压力传感器[J]. 激光与光电子学进展, 2019, 56(10): 100601.

[18] Zou T T, Zhao B, Xin W, et al. High-speed femtosecond laser plasmonic lithography and reduction of graphene oxide for anisotropic photoresponse[J]. Light: Science & Applications, 2020, 9: 69.

[19] Li Z Z, Wang L, Fan H, et al. O-FIB: far-field-induced near-field breakdown for direct nanowriting in an atmospheric environment[J]. Light:Science & Applications, 2020, 9: 41.

[20] Salter P S, Booth M J. Adaptive optics in laser processing[J]. Light, Science & Applications, 2019, 8: 110.

[21] Jiang L, Wang A D, Li B, et al. Electrons dynamics control by shaping femtosecond laser pulses in micro/nanofabrication:modeling, method, measurement and application[J]. Light: Science & Applications, 2018, 7(2): 17134.

[23] 李金健, 刘一, 曲士良. 飞秒激光微纳加工光纤功能器件研究进展[J]. 激光与光电子学进展, 2020, 57(11): 111402.

[24] Malinauskas M, Zukauskas A, Hasegawa S, et al. Ultrafast laser processing of materials: from science to industry[J]. Light: Science & Applications, 2016, 5(8): e16133.

[25] 陈招弟, 李纪超, 萧善霖, 等. 激光还原氧化石墨烯制备薄膜柔性电子器件[J]. 激光与光电子学进展, 2020, 57(11): 111428.

[26] Yuan Z Q, Chen H, Tang J X, et al. A novel preparation of polystyrene film with a superhydrophobic surface using a template method[J]. Journal of Physics D Applied Physics, 2007, 40(11): 3485.

[27] Oktay B, Toker R D, Kayaman-Apohan N. Superhydrophobic behavior of polyimide-siloxane mats produced by electrospinning[J]. Polymer Bulletin, 2015, 72(11): 2831-2842.

[28] Gong D W, Long J Y, Jiang D F, et al. Robust and stable transparent superhydrophobic polydimethylsiloxane films by duplicating via a femtosecond laser-ablated template[J]. ACS Applied Materials & Interfaces, 2016, 8(27): 17511-17518.

[30] Zhang Y L, Ma J N, Liu S, et al. A “Yin”-“Yang” complementarity strategy for design and fabrication of dual-responsive bimorph actuators[J]. Nano Energy, 2020, 68: 104302.

[31] Chen F Z, Lu Y, Liu X, et al. Table salt as a template to prepare reusable porous PVDF-MWCNT foam for separation of immiscible oils/organic solvents and corrosive aqueous solutions[J]. Advanced Functional Materials, 2017, 27(41): 1702926.

[33] Liu T, Li X F, Wang D H, et al. Superhydrophobicity and regeneration of PVDF/SiO2 composite films[J]. Applied Surface Science, 2017, 396: 1443-1449.

[34] Wu J D, Ding Y J, Wang J Q, et al. Facile fabrication of nanofiber- and micro/nanosphere-coordinated PVDF membrane with ultrahigh permeability of viscous water-in-oil emulsions[J]. Journal of Materials Chemistry A, 2018, 6(16): 7014-7020.

[36] Zhang P C, Lin L, Zang D M, et al. Designing bioinspired anti-biofouling surfaces based on a superwettability strategy[J]. Small, 2017, 13(4): 1503334.

[37] Viswanath P, Yoshimura M. Light-induced reversible phase transition in polyvinylidene fluoride-based nanocomposites[J]. SN Applied Sciences, 2019, 1(11): 1-9.

[39] Sultana T, Georgiev G L, Auner G, et al. XPS analysis of laser transmission micro-joint between poly (vinylidene fluoride) and titanium[J]. Applied Surface Science, 2008, 255(5): 2569-2573.

Article Outline

李纪超, 陈招弟, 韩冬冬, 张永来, 孙洪波. 超疏水聚偏氟乙烯的激光加工[J]. 中国激光, 2021, 48(2): 0202002. Jichao Li, Zhaodi Chen, Dongdong Han, Yonglai Zhang, Hongbo Sun. Laser Processing of Polyvinylidene Fluoride with Superhydrophobicity[J]. Chinese Journal of Lasers, 2021, 48(2): 0202002.