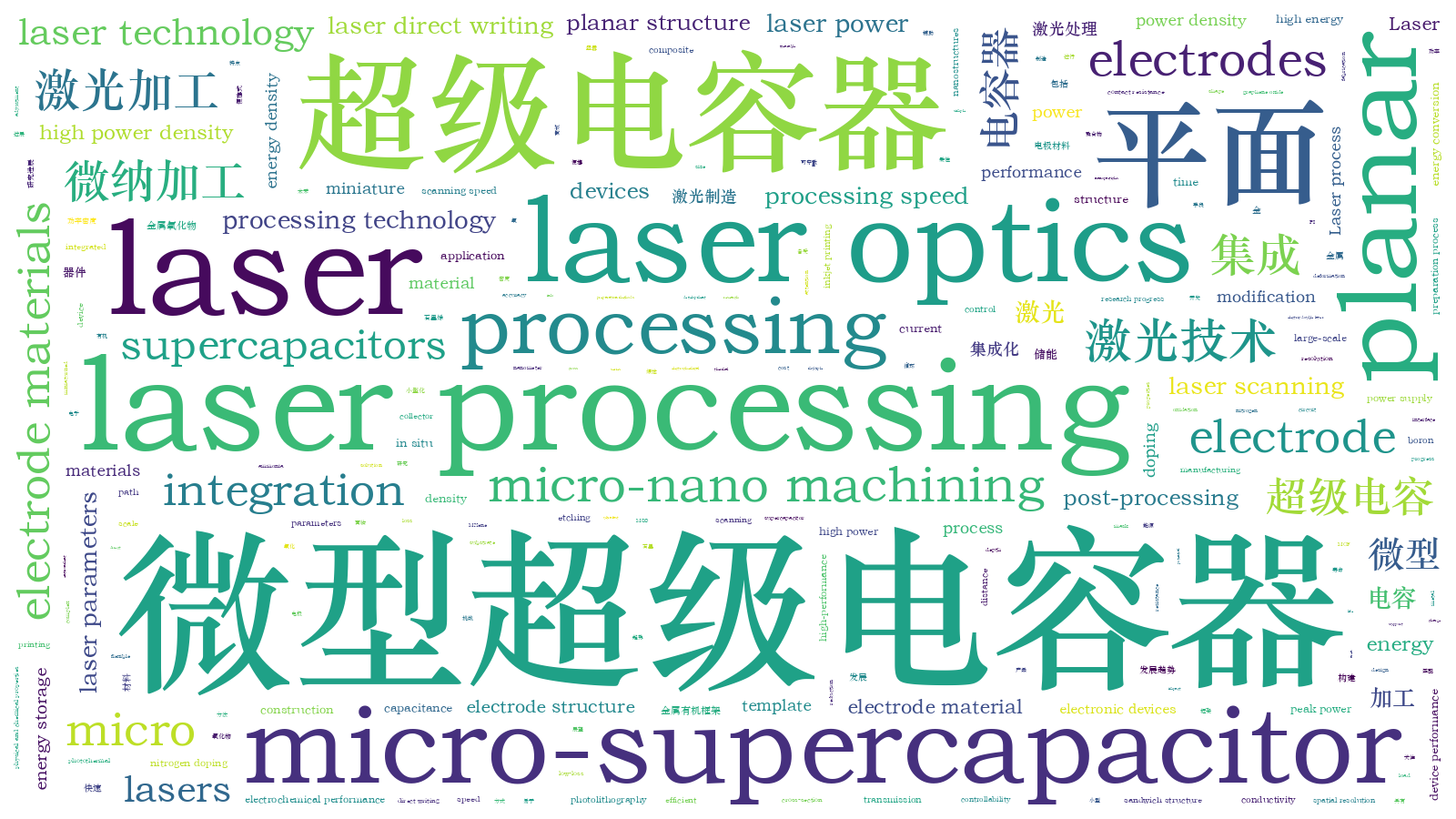

基于激光加工的平面型微型超级电容器  下载: 1961次特邀综述

下载: 1961次特邀综述

Significance Emerging portable wearable electronic devices require high-performance and integrable micropower sources. Micro-supercapacitors with high power density, rapid charge and discharge, and long life cycles have received widespread attention. Differing from the traditional sandwich structure, planar micro-supercapacitors do not require separators because their electrodes are on the same plane with certain physical distance, including parallel line, interdigital, and coil types, which significantly reduce the interface contact resistance and improve the electrochemical performance of the device. In addition, the ion transmission path of planar micro-supercapacitors would remain constant as the electrode load increases due to the unique vertical opposite cross-section electrode structure. This could increase energy density without losing power density. The miniaturized planar structure is considered highly compatible with microelectronic systems that can be integrated into other circuits as power supply units to provide effective peak power within a short time.

To date, various planar micro-supercapacitor construction methods have been developed, such as oxidation etching, printing, and photolithography technologies. However, some challenges remain. Oxidation etching technology involves multiple steps and complex operations, which, at minimum, requires a template to construct metal current collectors while removing the excess active material. Low-cost inkjet printing can be used to construct the current collector in a non-contact manner; however, the preparation process of the printable ink is complicated. Although photolithography technology is often used to prepare the planar electrode arrays of micro-supercapacitors, the post-processing procedures are cumbersome, which limits its application in the integrated manufacturing of microdevices. Compared with the above preparation methods, laser processing technology, which does not require a template and features high processing speed and nanometer spatial resolution, is a promising and efficient tool. Specifically, the designated electrode patterns can be precisely constructed using laser processing technologies on demand. For example, ultrafast lasers, which have instantaneous high energy with low thermal impact and negligible working area deformation, can also accurately control and fabricate microelectrodes in a short time. To improve overall performance, the physical and chemical properties, such as modification, doping, and electrode conductivity, can also be controlled in situ and regulated by adjusting laser parameters. Laser process technology has become increasingly important in the development of microdevices. Therefore, there is a great need to summarize the research progress of laser processing for micro-supercapacitors to provide references for the future design and preparation of advanced micro-energy storage devices.

Progress Due to its unique advantages, laser technology is widely used in the physical processing of electrode patterns and the modification of electrode materials for micro-supercapacitors. Laser technology can be employed to realize in situ fabrication or adjustment of micro- and nanostructures in electrodes and composite electrodes with pseudo capacitance and electric double layer capacitance. Thus, laser technology is considered an effective and convenient manufacturing strategy for micro-supercapacitors. More importantly, the capabilities of laser technology to realize the precise size and shape of microelectrodes as well as the possible for large-scale integration of various circuits provide a variety of potential application scenarios for micro-supercapacitors. In the physical construction of patterns, researchers have been able to effectively control the distance between adjacent electrodes by adjusting the processing accuracy of the laser, which can shorten the ion transmission path between two electrodes, thereby improving device performance. For example, adjustable finger-shaped microelectrodes were obtained simultaneously on the upper and lower surfaces of graphene oxide (GO) film, in part, to the flexible controllability of the laser. Surface capacitance could be further improved by connecting devices in series outside the plane. In addition, laser technology has also been used to realize a microelectrode current collector or mask, which usually acts as a substrate or template to realize microelectrodes through simple template imprinting, electrodeposition, and other methods. Laser processing technology has been deployed to facilitate efficient, large-scale production of miniature energy storage devices whereby hundreds of miniature devices can be produced in a short time. The advantages of lasers are also reflected in the fast and effective integration of different circuit components to support low-loss energy conversion.Research on electrode modification revealed that adjusting laser scanning parameters, such as laser power and scanning speed, affected the conductivity of some specific electrodes to a certain extent, such as the use of laser photothermal reduction of GO materials. In addition, doping and modifying nanoparticles or atoms in microelectrodes could also be performed in situ using laser direct writing technology. In this regard, various composite electrodes and heteroatom doped electrodes were obtained by laser processing the raw material containing functional components. For example, boron-doped electrode materials were successfully prepared by laser processing a PI sheet containing boron elements. Moreover, the heteroatom doping process has also been achieved by placing the electrode material in a special environment for laser processing. For example, nitrogen doping of GO material was prepared in the presence of ammonia by irradiating the GO solution with a laser.

Conclusion and Prospect Currently, the primary role of lasers in the construction of miniature supercapacitors is physical marking and electrode modification. Due to their unique advantages, lasers have gradually become a popular tool for preparing micro-supercapacitors. However, this process still requires in-depth and detailed exploration to promote the comprehensive application of this processing technology in miniature energy storage devices.

1 引言

随着可穿戴式智能电子产品的快速发展,迫切需要开发微型化、柔性可集成的储能设备与之兼容[1-2]。其中,微型超级电容器(MSC)因具有功率密度高、充放电快速及循环寿命长等特点受到广泛关注,但其短板是能量密度较低[3-4]。与传统三明治结构不同,平面型微型超级电容器的两电极处于同一平面且有一定的物理距离,其类型有平行线型、叉指型、线圈型等,这类构型的微型超级电容器不需要隔膜类材料,可大幅度降低界面接触电阻,利于提高器件的电化学性能[5-6]。更重要的是,平面型微型超级电容器主要利用两电极相对的截面进行能量转换,其离子传输路径不随电极负载量的增加而发生变化,能在提高能量密度的同时不损失功率密度[7-8];而且平面结构与微电子系统兼容,可以将其集成到其他电路中作为电源单元[9-10],可在瞬间提供有效的功率峰值。与传统超级电容器类似,微型超级电容器按照储能机制可以分为双电层(EDL)超级电容器和赝电容超级电容器[11]。EDL通过电解液中离子在电极表面的物理吸脱附来实现电荷的储存和释放,所以EDL电容器具有充放电速率快的特点[12];赝电容超级电容器的能量转换主要依赖于电极表面附近的电解质和活性材料之间的可逆氧化还原反应[13],因此可以提供较EDL更高的能量密度,然而在充放电过程中,活性物质材料的结构完整性易受到破坏,从而影响其使用寿命。研究人员发现可以对机械性能优异的EDL材料与发生氧化还原反应的赝电容材料进行复合[14-15],期望同时实现微器件的高能量和功率密度。

激光加工技术是一种利用光源与基底之间的相互作用,对基底材料(包括金属与非金属)进行切割、表面处理及内部结构调控的非接触式制造技术,具有分辨率高、可选区、集成化及改性制备等特点,因而得到了广泛应用[16-20]。例如,硬度材料的成型处理[21]、透明材料的局部结晶[22]、创建超疏水涂层[23]、诱导溶液中金属沉积[24]、制备多孔三维石墨烯用于各种微型场景下的传感器[25]、驱动器[26]、微型储能器件[27]及热电发电机[28]等。

激光加工技术在构建储能器件方面具有一定的潜力。例如,激光加工技术通过设计基底的方式得到透明且具有强韧性的聚二甲基硅氧烷(PDMS)薄膜[29],有望用于封装有机体系的储能器件;激光加工可以用来设计电极材料,长脉冲纳秒激光烧蚀可以生成高度无序掺杂Ni的Fe3O4纳米粒子簇[30];制造分层的纳米结构金属氧化物(MOx,M=Ti,Mn,Fe,Co,Ni,Cu,Mo,Ag,Sn,W,NiFe);在集电器上原位制备CuO-Cu[31]、Co-CoO[32]集成阳极。飞秒(fs)激光可以通过调整加工参数制造具有不同形貌的微/纳米界面结构,从而全面增强W/Cu连接的结合强度[33-34],可用于集流体与电极材料之间的连接。

平面型微型超级电容器的构建方法有很多,例如氧化刻蚀技术、打印技术和光刻技术等,但是这些技术仍然存在一些缺点。采用氧化刻蚀技术制备微器件时,需要模板才能完成金属集流体的沉积,随后要把多余的活性材料洗掉,不仅操作复杂还造成了材料的浪费。喷墨打印技术能够以非接触的方式实现集流体的构建,在一定程度上节约了成本,但是可印刷油墨的制备过程十分复杂。此外,光刻技术虽常用于制备微型超级电容器的平面电极阵列,但该技术的后期处理程序繁琐,限制了其在微器件集成化制造方面的应用。相比于上述构建微型器件的方法[35-38],激光加工技术价格低廉、操作简单、无需模板,可以从多方面来辅助构建微型超级电容[39-41]。一方面,激光加工可按照预设构图信息对基底、电极材料进行选区处理,由于激光具有高的能量密度,可快速完成加工任务,热影响小,工作区域变形小,可以精确地调控两电极之间的距离及灵活地设计多样化的微电极图案,而且激光选区加工展现出强大的系统集成能力,具有很大的实际应用前景;另一方面,激光加工还可以在一定程度上通过激光释放的光热能量对材料的结构进行调控,从而改善微型器件的电化学性能,实现电极电导率的可控调节、完成电极材料的原位掺杂和原位修饰等,甚至可以引入赝电容材料来提高平面型微型超级电容器的整体性能。

鉴于此,本文综述了激光加工平面型微型超级电容器的研究进展,包括激光辅助构建微型超级电容器的方式、典型的激光加工构建的微型超级电容器及其电极材料,材料包括石墨烯类、MXene类、金属氧化物类、聚合物类、金属有机框架(MOF)类,并且展望了激光加工微型超级电容器未来的发展趋势和面临的挑战。

2 激光辅助方式

激光辅助构建微型超级电容器的方式主要体现在物理构图的灵活性和电极材料的改性方面。灵活的物理构图可以实现微电极的尺寸、形状、维度等方面的多样设计和各种电路的大规模集成,为微型超级电容器提供各种各样的潜在应用场景;电极改性是改善微型超级电容器性能的主要方式之一,通过一步激光加工处理可以有效调整电极的结构和性能,甚至可以原位制备出具有赝电容和双电层电容的复合材料[42-43]。因此,激光辅助构建微型超级电容器是一种高效便捷的制备策略。针对不同辅助方式,需要选择合适的激光进行加工。比如精确的物理标刻构图,其需要在不产生大量热的情况下完成,可以选择超快激光进行处理[44],例如飞秒激光、皮秒激光;电极改性,需要考虑电极材料对不同波长的激光吸收机制,例如聚酰亚胺(PI)对10.6μm的波长光有很强的吸收,PI可以吸收光并将其大量转变为热,故CO2激光可以用来烧蚀PI;金属对短波长光有强吸收,则可以选择光纤激光等。

2.1 物理构图

激光加工是一种非接触式制造技术,可以根据计算机图形信息对电极材料进行选区雕刻处理,构建出不同形状和尺度的电子器件[45-47]。例如,通过调节激光的加工精度,能够有效控制相邻电极间的距离,从而减短两电极间离子的传输路径,进而改善器件性能[48]。借助激光可灵活控制的特点,Kwon等[49]在氧化石墨烯(GO)膜的上下两个表面同时获得叉指状的微电极,连接后得到面外串联的器件结构,通过成倍地增加面电容的方式提高器件的能量密度。另外,还可以利用激光来设计微型电极的模板,随后经过简单的模板压印[50]、电沉积[46]等方式得到微型储能器件。更重要的是,激光加工技术可以大面积、规模化制备微型储能器件[47,51],一步完成上百个微型器件的快速集成,获得理想的能量输出。例如,Li等[52]利用激光加工技术在PI胶带上成功集成了209个微型器件,可驱动小型机器人正常工作11s,这在微型储能器件的应用中是一个非常大的突破。不仅如此,激光的构图优势还体现在快速实现不同电路元件的高效集成,使之实现低损耗的能量转换。Luo等[53]将摩擦电纳米发电机电路和微型超级电容器阵列(MSCA)集成到单个设备中,制造了柔性自充电微型超级电容器功率单元(SCMPU),其利用环境机械能实现微型超级电容器的可持续性充电,具有很大的实际应用前景。上述研究表明,由激光一步完成的电路集成可以用于高电压、可持续自供电系统。激光在微型器件的物理构图方面发挥了巨大的作用,通过激光辅助可实现各种形状的微型储能器件的构建、模板设计、电极调整及电路集成,这些工作可以为微型超级电容器的制备提供更多便利。

2.2 电极改性

2.2.1 原位直写

激光可以在计算机控制下根据设计的图形信息直接对电极材料进行“烧蚀”处理,从而达到电极改性的目的[39]。激光加工技术可以通过各种前驱体来制备电极[54-57],经典的例子是用激光直接选区还原GO纤维,制备出具有优异机械柔韧性的单纤维超级电容器[58],其可以编织到纺织品中用于可穿戴电子产品。研究人员发现通过调整激光扫描参数(激光功率,扫描速度等)能够不同程度地影响材料的性能[59-61]。Li等[62]直接用飞秒激光原位还原GO和氯金酸(HAuCl4)的混合溶液,一步合成还原氧化石墨烯与金(Au)集流体并存的电极,大大提高了电极电导率,进而改善了器件的电化学性能。除此之外,激光直写技术还可以用来制备高电导率的集电器[63-64]和电解质[65]。总之,激光直写技术的合理设计和应用,可以实现微型超级电容器的电极电导率的调整、集电器和电解质的制备,为激光辅助构建微型超级电容器的发展开拓了广阔的空间。

2.2.2 原位增材

原位增材处理指的是在激光加工过程中,将纳米粒子、原子等掺杂或修饰在电极表面的行为[42,66],使得纳米复合材料具有良好的电化学性能。激光诱导纳米颗粒在电极表面掺杂和修饰,可以通过对含有相关纳米粒子的物质进行激光处理,得到复合的电极材料[67-69]。例如,对含硼原子的PI薄板进行激光处理,制备了掺硼电极材料[70];Clerici等[71]在激光直写过程中通过在PI表面覆盖一层MoS2分散体,即可获得MoS2原位装饰的多孔石墨烯网络,所得材料具有良好的导电性能和大比表面积,适合用作超级电容器的电极,从而实现双电层和赝电容的共同表达;还可以通过将电极材料置于特殊环境中进行激光加工实现杂原子掺杂[72];在氨水存在的情况下,用激光辐照GO溶液,可以实现GO的选择性氮掺杂[73]。激光加工技术可以便捷巧妙地实现电极材料的掺杂和修饰,更加突出了激光辅助构建微型超级电容器的优势。

3 激光加工的平面型微型超级电容器

目前常用于构建微型超级电容器的激光器主要有光纤激光器、紫外激光器、CO2激光器和半导体激光器。CO2激光器价格低廉、光热转换效率高、易于改善电极结构[74]、操作简单,受到了研究人员的青睐。飞秒/皮秒激光器虽然价格昂贵,但由于具有超短脉宽,脉冲连续时间远远小于材料内部受激电子的弛豫时间,可实现相对意义上的“冷加工”[75]。紫外激光器具有成本低、加工精度高等优势[76]。激光应用于平面型微型超级电容器的构建主要在以下方面发挥作用:激光直写还原电极材料;激光诱导电极材料改性或实现原位掺杂;激光雕刻精确控制两电极之间的物理距离;激光高效集成电子器件阵列,完成大能量输出。

3.1 石墨烯类

石墨烯(graphene)是一种由碳原子以sp2杂化轨道组成六角型呈蜂巢晶格结构的二维纳米材料,具有大的比表面积和电导率、多孔结构、优良的柔韧性特点,是理想的双电层电容电极材料。构建石墨烯基微型超级电容器时,主要依靠激光与碳源材料之间的光热作用,进行还原GO及引入新的物质构成高性能电极,例如激光还原GO[49,51,77]、激光直写PI[52]、激光掺杂石墨烯[78-79]、激光制备石墨烯的复合材料[80-81]等。

大多数关于激光制备石墨烯基微型超级电容器的报道通常以GO作为起始原料[82-84],而GO的制备过程繁琐且耗时,无形中增加了微电容器制备的复杂度。与之相比,激光直接诱导聚合物材料获得多孔的激光诱导石墨烯(LIG)的过程[56-57,85],较大程度地简化制备工艺并降低制造成本。据报道,LIG不同的微纳米结构可以通过调整激光辐射的能量实现[60]。碳化过程的启动需要5J/cm2的能量。当激光辐射通量继续增加时,PI膜中气体快速排出,经历流体破碎过程;LIG的物理形成遵循流体动力学过程,其形态从薄片逐渐变为纤维(LIGF)(>40J/cm2),最后变为液滴。将得到的电极材料分别组装成微型超级电容器,可以发现,将LIGF掺入LIG中制备微型超级电容器,电容性能较纯LIG有2倍提升,主要归因于激光不同的辐射能量调整了电导率和电解质离子传输的路径。

Shi等[86]用计算机控制的商用激光器(波长为450nm,最大功率为2.0 W,划线速度约为4mm·s-1)对PI膜进行烧蚀,一步成功制备出具有高性能的石墨烯基微型超级电容器。激光对PI膜进行一步光热转换处理,形成具有各种平面几何形状的LIG微电极,有叉指状、半圆状及平行状,如

![全固态MSCs的制备示意图及其电镜照片[86]](/richHtml/zgjg/2021/48/2/0202013/img_1.jpg)

图 1. 全固态MSCs的制备示意图及其电镜照片[86]

Fig. 1. Schematic of the preparation of all-solid MSCs and their electron micrographs[86]

紫外激光器结合了CO2激光器和飞秒激光器的优势,具有低成本和高精度的优势。在制备大规模集成化的石墨烯基微型超级电容器方面,Ye等[87]选择紫外激光器(激光功率约为1W,扫描速度为200mm·s-1)在化学气相沉积(CVD)生长的堆叠石墨烯薄膜上精确雕刻出电极之间的间隙,制造了大面积的基于多层石墨烯的微型超级电容器(MG-MSC),如

![柔性MSCs制备、集成示意图及其电子照片[87]](/richHtml/zgjg/2021/48/2/0202013/img_2.jpg)

图 2. 柔性MSCs制备、集成示意图及其电子照片[87]

Fig. 2. Schematic of the preparation, integration, and electronic photos of flexible MSCs[87]

激光加工技术还可以通过设计不同的模板进行微型超级电容器的构建。Shi等[88]利用可在0~5W内调节功率的激光雕刻机处理光敏材料(闪光泡沫),得到电极模板,进而实现纸基微型超级电容器的构建。闪光泡沫是一种具有数十微米孔径的气泡材料,微孔在激光照射下会闭合,从而隔离油性物质。因此,作者利用激光雕刻将预先设计的电极图案转移到闪光泡沫上,以形成闪光泡沫辅助的印模。将模型浸泡于PDMS和固化剂的混合物溶液中10 min,固化后将电极模板压印在纸张上,接着用闪光泡沫的封闭微孔区域吸收电化学剥离制备的石墨烯溶液后,形成纸基石墨烯电极,如

3.2 MXene类

MXene作为一种二维(2D)碳化物和氮化物材料,由于具有优越的金属导电性(高达6500S·cm-1)、亲水性表面、出色的离子嵌入行为受到越来越多的关注。它被认为是比石墨烯或其他二维材料更有前途的材料。

Kurra等[89]利用CO2激光束高的光热转换效率,以蛇形方式在附着有高电导率MXene的打印纸上移动激光束,来雕刻交叉指状的图案。由于局部高温会烧掉底部的纸张支撑物,因此构建了纸基平面微型超级电容器,如

Jiao等[91]通过CO2激光的构图工艺将具有优异机械强度的独立式轻质MXene/细菌纤维素(BC)复合纸切割成高度可拉伸的形状,用于构建高能量密度和拉伸稳定性的微型超级电容器,如

![可拉伸全固态平面MSCA的制造示意图[91]](/richHtml/zgjg/2021/48/2/0202013/img_5.jpg)

图 5. 可拉伸全固态平面MSCA的制造示意图[91]

Fig. 5. Schematic of the manufacture of a stretchable all-solid planar MSCA[91]

飞秒激光因“冷加工”和高精度的特点,被广泛应用于微纳加工制造领域。Li等[92]利用飞秒激光的高精确度和同步刻蚀的能力在PET上成功制备了双面的微型超级电容器(DSMSC),以期通过增加电容来提高器件的能量密度,同时有效地改善MSCA的集成并提高微器件使用面积的利用率,如

![DSMSCs制备示意图及其电子照片[92]](/richHtml/zgjg/2021/48/2/0202013/img_6.jpg)

图 6. DSMSCs制备示意图及其电子照片[92]

Fig. 6. Schematic of the preparation of DSMSCs and their electronic photos[92]

3.3 金属氧化物类

金属氧化物作为典型的赝电容电极材料,应用于微型超级电容器时,被证实是提高能量密度的一种有效方法。然而,设计和制造平面型赝电容微型超级电容器面临着很大的挑战。基于金属氧化物及其复合材料的微型超级电容器的制备方法往往过程繁杂、耗时耗能、效率低下。因此,发展一种廉价、快速的一步法制备工艺对金属氧化物及其复合材料的实际应用具有重要的科学意义。激光加工技术的出现解决了这个问题,激光可以通过设计掩模板或者构建功能性基底的方式轻松制备微型超级电容器,节约成本的同时大大提高了效率。

在过渡金属氧化物中,RuO2·xH2O(含水RuO2,hRuO2)由于混合的质子-电子传导而具有较高的理论能量密度。Huang等[93]使用商用激光打印机在PET板上用墨粉成功制备出微型超级电容器的牺牲模板(叉指宽度为300μm,两电极间隙为150μm),喷溅上Pt薄膜作为金属集流器,通过浸泡RuCl3和NaOH溶液来制备RuOxHy层,最后用丙酮、水超声洗去牺牲模板,并进行退火,即可获得负载有电极材料hRuO2和集流体的电极,对电极覆盖上凝胶电解质,干燥后可得到大规模的基于RuO2的全固态柔性微型超级电容器,如

CO2激光器的波长通常为10.6μm,PI作为一种对此波段光吸收很强的聚合物,能够将大部分光能转变为热能,CO2激光器将PI诱导为多层石墨烯和不定形碳等物质。Zhang等[94]利用CO2激光器在PI上(水接触角为49°)采用激光处理技术得到3D激光标刻石墨烯(LSG,水接触角为129°)微型集电器,利用LSG和未转化的PI对水的巨大润湿性差异,发明了润湿性驱动自组装(WDA)工艺,如

![湿度自驱动组装MSC的制备示意图[94]](/richHtml/zgjg/2021/48/2/0202013/img_8.jpg)

图 8. 湿度自驱动组装MSC的制备示意图[94]

Fig. 8. Schematic of the preparation of a MSC assembled by humidity self-driving[94]

Brousse等[95]通过紫外激光直写技术得到了大规模可集成的基于RuO2的微型超级电容器。如

3.4 聚合物类

尽管常规的无机2D材料在储能装置中显示出巨大的潜力,但由于难以实现大面积及超薄结构的制备,基于这些材料的小型化储能装置制备仍然面临挑战。半导体2D聚合物有望成为开发高效储能设备的一种新的有吸引力的材料选择。为此,Jiang等[96]通过界面聚合方法合成了大面积的苯桥聚吡咯薄膜,并将其用于微型超级电容器。如

![MSCs制备示意图及其相关表征[96]](/richHtml/zgjg/2021/48/2/0202013/img_10.jpg)

图 10. MSCs制备示意图及其相关表征[96]

Fig. 10. Schematic of the preparation of MSCs and their related characteristics[96]

为了进一步满足实际应用对智能储能设备的日益增长的需求,需要开发新型的微型超级电容器用于存储可再生能源。本课题组开发了以商业打印纸作为柔性基底的聚吡咯/石墨烯基对称微型超级电容器(PPyG-MSC)阵列,并将其用于风能的收集及自充电[50]。光纤激光器采用光纤作增益介质,散热快、损耗低, 所以光纤激光器具有转换效率高、激光阈值低的特点。使用光纤激光器对铝箔刻蚀出电极模板,将切好的PPyG片置于铝模板叉指上,并进行加压,得到嵌入纸的叉指状电极,如

![纸基MSCs和风能收集器的制备示意图[50]](/richHtml/zgjg/2021/48/2/0202013/img_11.jpg)

图 11. 纸基MSCs和风能收集器的制备示意图[50]

Fig. 11. Schematic of the preparation of paper-based MSCs and wind energy collectors[50]

3.5 金属有机骨架(MOF)类

MOF指的是一种过渡金属离子与有机配体通过自组装形成的具有周期性网络结构的晶体多孔材料,具有高孔隙率、低密度、大比表面积、有孔道规则、孔径可调等优点,成为电化学储能应用中有潜力的电极材料之一。研究人员发现通过激光加工技术处理MOF,可以一步得到多孔碳材料与金属纳米颗粒/金属氧化物复合的材料[97],双电层和赝电容电极材料的存在为其应用于储能器件奠定了基础。

微电子设备和系统的快速发展促使便携式电源的开发和利用逐渐受到关注和重视,目前大量的研究重点主要集中在功能性材料的平面叉指型能量存储设备的开发。例如,Basu等[98]利用长波长的CO2激光完成了电极的制备,通过激光直写技术处理含锌的MOF——沸石咪唑酸酯骨架(ZIF-67),得到金属修饰、杂原子掺杂、多孔少层石墨烯电极(LIMDG),并将其用于微型超级电容器,如

导电2D MOF在电化学应用方面具有超越传统MOF的优点,Wu等[99]开发了一种具有良好导电性的邻苯二酚镍的MOF(Ni-CAT MOF)材料用于MSC。如

![电极制备示意图及对应的分子模型[99]](/richHtml/zgjg/2021/48/2/0202013/img_13.jpg)

图 13. 电极制备示意图及对应的分子模型[99]

Fig. 13. Schematic of electrode preparation and corresponding molecular model[99]

4 结果与展望

综述了激光加工平面型微型超级电容器的研究进展,重点介绍了激光辅助构建微型超级电容器的方式和典型激光加工的微型超级电容器。激光加工技术是一种非接触式的制造技术,一方面它可以根据需要设计不同形状的微型超级电容器,通过调整两电极之间的距离,减小离子扩散的路径,一步完成器件之间的串并联及与商用电路的集成,实现能量的可控输出和储存;另一方面,激光加工产生的光和热可用于调节活性材料的结构和性能,进而改善充放电过程中离子与电极之间的相互作用。激光加工技术还可以用来制备微型超级电容器的集流体[100]和电解液,甚至有望使用基于激光制备的PDMS膜封装有机体系的微型超级电容器,实现全激光制造的平面型微型超级电容器。更重要的是,激光在标刻电极材料的同时可以实现材料的原位掺杂、原位修饰,得到的复合材料可用作微型超级电容器的电极材料,电化学性能可以得到更充分的表达,如

尽管激光辅助构建微型超级电容器得到了很好的发展,但是仍然存在亟待解决的问题。首先,激光辅助加工技术的效率和切割方向问题。激光加工技术构建图案的方式是点对点曝光和逐行扫描的,而且激光辅助加工电极材料的角度有限,导致不可以随心所欲地设计电极材料,造成了时间成本和激光能量的浪费,表现出较低的制造效率和较高的构图局限性,限制了微型电容器的大量生产。为此,一种思路是可以采用来自不同方向的多激光束共同作用[101],其有望在提高效率的同时能够得到多元化设计的电极材料,从根本上解决激光加工效率低的问题,实现电子设备的大规模激光制造。另外,微型超级电容器的短板在于低的能量密度,尽管目前已经提出了很多方法去改善,比如使用负载量较多的3D电极、在电极上修饰赝电容材料等,然而激光参与辅助的通过拓宽电压窗口去提高能量密度的工作比较少,利用激光辅助构建不对称的微型超级电容器、混合型的微型超级电容器还面临挑战。另一种思路是可以利用不同波长的激光对前驱体材料进行局部光聚合、光还原等,得到高性能的电极材料,并用于构建微型超级电容器。还有一种思路是可以发展激光辅助制备高电压的电解液,从而提高微型超级电容器的能量密度。

表 1. 基于激光加工的平面型MSCs电化学性能

Table 1. Electrochemical performance of planar MSCs based on laser processing

|

综上所述,通过合理设计活性电极材料的组成、电解液的制备及多光束激光加工技术的实施过程,可进一步提高激光辅助构建微型超级电容器的能量密度。激光辅助构建的微型超级电容器的快速发展,有望满足市场对高电压、高功率密度和能量密度、自充电的微型储能器件的需求,实现在较短的时间内为微型电子设备提供足够的能量和令人满意的输出功率,为未来新型电子产品制备提供新思路。

[2] Beidaghi M, Gogotsi Y. Capacitive energy storage in micro-scale devices: recent advances in design and fabrication of micro-supercapacitors[J]. Energy & Environmental Science, 2014, 7(3): 867-884.

[3] Yu L H, Fan Z D, Shao Y L, et al. Versatile N-doped MXene ink for printed electrochemical energy storage application[J]. Advanced Energy Materials, 2019, 9(34): 1901839.

[5] Wu M M, Li Y R, Yao B W, et al. A high-performance current collector-free flexible in-plane micro-supercapacitor based on a highly conductive reduced graphene oxide film[J]. Journal of Materials Chemistry A, 2016, 4(41): 16213-16218.

[7] Yoo J J, Balakrishnan K, Huang J, et al. Ultrathin planar graphene supercapacitors[J]. Nano Letters, 2011, 11(4): 1423-1427.

[8] Liu Y Q, Weng B, Xu Q, et al. Facile fabrication of flexible microsupercapacitor with high energy density[J]. Advanced Materials Technologies, 2016, 1(9): 1600166.

[9] Peng Y Y, Akuzum B, Kurra N, et al. All-MXene (2D titanium carbide) solid-state microsupercapacitors for on-chip energy storage[J]. Energy & Environmental Science, 2016, 9(9): 2847-2854.

[10] Cai J G, Lv C, Watanabe A. Laser direct writing and selective metallization of metallic circuits for integrated wireless devices[J]. ACS Applied Materials & Interfaces, 2018, 10(1): 915-924.

[11] Wang X Z, Zhang Q M. On-chip microsupercapacitors: from material to fabrication[J]. Energy Technology, 2019, 7(11): 1900820.

[12] Yadav P, Basu A, Suryawanshi A, et al. Highly stable laser-scribed flexible planar microsupercapacitor using mushroom derived carbon electrodes[J]. Advanced Materials Interfaces, 2016, 3(11): 1600057.

[13] Li X X, Ma Y N, Shen P Z, et al. Self-healing microsupercapacitors with size-dependent 2D MXene[J]. ChemElectroChem, 2020, 7(3): 821-829.

[14] Wang S L, Wang Q, Zeng W, et al. A new free-standing aqueous zinc-ion capacitor based on MnO2-CNTs cathode and MXene anode[J]. Nano-Micro Letters, 2019, 11(1): 70.

[15] Zhang P P, Wang L L, Wang F X, et al. A nonaqueous Na-ion hybrid micro-supercapacitor with wide potential window and ultrahigh areal energy density[J]. Batteries & Supercaps, 2019, 2(11): 918-923.

[16] Sohajda Z, Széll N, Revák Á, et al. Retinal nerve fibre layer thickness change after CO2 laser-assisted deep sclerectomy surgery[J]. Clinical Ophthalmology, 2020, 14: 1749-1757.

[17] Doğanay Yıldız E, Dinçer B, Fidan M E. Effect of different laser-assisted irrigation activation techniques on apical debris extrusion[J]. Acta Odontologica Scandinavica, 2020, 78(5): 332-336.

[18] Abdul Salam A A, Shilpa T, George S D, et al. Laser-assisted crystallization: an alternative tool to crystallize biomolecules[J]. Acta Crystallographica Section A Foundations and Advances, 2017, 73(a2): C351.

[19] Noh J H, Fowlkes J D, Timilsina R, et al. Pulsed laser-assisted focused electron-beam-induced etching of titanium with XeF2: enhanced reaction rate and precursor transport[J]. ACS Applied Materials & Interfaces, 2015, 7(7): 4179-4184.

[20] Waibel J S, Wulkan A J, Shumaker P R. Treatment of hypertrophic scars using laser and laser assisted corticosteroid delivery[J]. Lasers in Surgery and Medicine, 2013, 45(3): 135-140.

[21] Liu X Q, Chen Q D, Guan K M, et al. Dry-etching-assisted femtosecond laser machining[J]. Laser & Photonics Reviews, 2017, 11(3): 1600115.

[22] Huang X, Guo Q, Kang S, et al. Three-dimensional laser-assisted patterning of blue-emissive metal halide perovskite nanocrystals inside a glass with switchable photoluminescence[J]. ACS Nano, 2020, 14: 3150-3158.

[23] Sataeva N E, Boinovich L B, Emelyanenko K A, et al. Laser-assisted processing of aluminum alloy for the fabrication of superhydrophobic coatings with standing multiple degradation factors[J]. Surface and Coatings Technology, 2020, 397: 125993.

[24] Manshina A, Povolotskiy A, Ivanova T, et al. Laser-assisted metal deposition from CuSO4-based electrolyte solution[J]. Laser Physics Letters, 2007, 4(2): 163-167.

[25] Cai J G, Lv C, Aoyagi E, et al. Laser direct writing of a high-performance all-graphene humidity sensor working in a novel sensing mode for portable electronics[J]. ACS Applied Materials & Interfaces, 2018, 10(28): 23987-23996.

[26] Cheng H H, Zhao F, Xue J L, et al. One single graphene oxide film for responsive actuation[J]. ACS Nano, 2016, 10(10): 9529-9535.

[27] Boruah B D, Maji A, Misra A. Flexible array of microsupercapacitor for additive energy storage performance over a large area[J]. ACS Applied Materials & Interfaces, 2018, 10(18): 15864-15872.

[28] Yu Y D, Zhu W, Wang Y L, et al. Towards high integration and power density: Zigzag-type thin-film thermoelectric generator assisted by rapid pulse laser patterning technique[J]. Applied Energy, 2020, 275: 115404.

[29] Gong D W, Long J Y, Jiang D F, et al. Robust and stable transparent superhydrophobic polydimethylsiloxane films by duplicating via a femtosecond laser-ablated template[J]. ACS Applied Materials & Interfaces, 2016, 8(27): 17511-17518.

[30] Cai M Y, Pan R, Liu W J, et al. Laser-assisted doping and architecture engineering of Fe3O4 nanoparticles for highly enhanced oxygen evolution reaction[J]. ChemSusChem, 2019, 12(15): 3562-3570.

[31] Liang P, Zhang H J, Su Y B, et al. In situ preparation of a binder-free nano-cotton-like CuO-Cu integrated anode on a current collector by laser ablation oxidation for long cycle life Li-ion batteries[J]. Journal of Materials Chemistry A, 2017, 5(37): 19781-19789.

[32] Liang P, Zhang H J, Pan B Y, et al. Binder-free carbon-coated nanocotton transition metal oxides integrated anodes by laser surface ablation for lithium-ion batteries[J]. Surface and Interface Analysis, 2019, 51(8): 874-881.

[33] Jiang D F, Long J Y, Cai M Y, et al. Femtosecond laser fabricated micro/nano interface structures toward enhanced bonding strength and heat transfer capability of W/Cu joining[J]. Materials & Design, 2017, 114: 185-193.

[34] Jiang D F, Long J Y, Han J P, et al. Comprehensive enhancement of the mechanical and thermo-mechanical properties of W/Cu joints via femtosecond laser fabricated micro/nano interface structures[J]. Materials Science and Engineering: A, 2017, 696: 429-436.

[35] Li Y Q, Shi X M, Lang X Y, et al. Remarkable improvements in volumetric energy and power of 3D MnO2 microsupercapacitors by tuning crystallographic structures[J]. Advanced Functional Materials, 2016, 26(11): 1830-1839.

[36] Zhou F, Huang H, Xiao C, et al. Electrochemically scalable production of fluorine-modified graphene for flexible and high-energy ionogel-based microsupercapacitors[J]. Journal of the American Chemical Society, 2018, 140(26): 8198-8205.

[37] Liu W, Lu C, Wang X, et al. High-performance microsupercapacitors based on two-dimensional graphene/manganese dioxide/silver nanowire ternary hybrid film[J]. ACS Nano, 2015, 9(2): 1528-1542.

[38] Lim Y, Yoon J, Yun J, et al. Biaxially stretchable, integrated array of high performance microsupercapacitors[J]. ACS Nano, 2014, 8(11): 11639-11650.

[39] Cheng H H, Ye M H, Zhao F, et al. A general and extremely simple remote approach toward graphene bulks with in situ multifunctionalization[J]. Advanced Materials, 2016, 28(17): 3305-3312.

[40] Wang Y N, Wang Y, Zhang P P, et al. Laser-induced freestanding graphene papers: a new route of scalable fabrication with tunable morphologies and properties for multifunctional devices and structures[J]. Small, 2018, 14(36): 1802350.

[41] Paterno L G, et al. Laser reduction of graphene oxide/zinc oxide nanoparticle nanocomposites as a one-step process for supercapacitor fabrication[J]. Physica Status Solidi (a), 2020, 217(11): 1901046.

[42] Wang W T, Lu L S, Xie Y X, et al. A highly stretchable microsupercapacitor using laser-induced graphene/NiO/Co3O4 electrodes on a biodegradable waterborne polyurethane substrate[J]. Advanced Materials Technologies, 2020, 5(2): 1900903.

[43] Wang W T, Lu L S, Xie Y X, et al. Tailoring the surface morphology and nanoparticle distribution of laser-induced graphene/Co3O4 for high-performance flexible microsupercapacitors[J]. Applied Surface Science, 2020, 504: 144487.

[44] 吴雪峰, 尹海亮, 李强. 飞秒激光加工碳纳米管薄膜试验研究[J]. 中国激光, 2019, 46(9): 0902002.

[45] Gao J, Shao C X, Shao S X, et al. Laser-assisted large-scale fabrication of all-solid-state asymmetrical micro-supercapacitor array[J]. Small, 2018, 14(37): 1801809.

[46] Pu X, Liu M M, Li L X, et al. Wearable textile-based in-plane microsupercapacitors[J]. Advanced Energy Materials, 2016, 6(24): 1601254.

[48] Yoo J, Byun S, Lee C W, et al. Precisely geometry controlled microsupercapacitors for ultrahigh areal capacitance, volumetric capacitance, and energy density[J]. Chemistry of Materials, 2018, 30(12): 3979-3990.

[49] Kwon S, Jung D, Lim H, et al. Laser-assisted selective lithography of reduced graphene oxide for fabrication of graphene-based out-of-plane tandem microsupercapacitors with large capacitance[J]. Applied Physics Letters, 2017, 111(14): 143903.

[50] Gao C, Gao J, Shao C X, et al. Versatile origami micro-supercapacitors array as a wind energy harvester[J]. Journal of Materials Chemistry A, 2018, 6(40): 19750-19756.

[51] El-Kady M F, Kaner R B. Scalable fabrication of high-power graphene micro-supercapacitors for flexible and on-chip energy storage[J]. Nature Communications, 2013, 4: 1475.

[52] Li X, Cai W, Teh K S, et al. High-voltage flexible microsupercapacitors based on laser-induced graphene[J]. ACS Applied Materials & Interfaces, 2018, 10: 26357-26364.

[53] Luo J J, Fan F R, Jiang T, et al. Integration of micro-supercapacitors with triboelectric nanogenerators for a flexible self-charging power unit[J]. Nano Research, 2015, 8(12): 3934-3943.

[54] Zhang W L, Lei Y J, Ming F W, et al. Lignin laser lithography: a direct-write method for fabricating 3D graphene electrodes for microsupercapacitors[J]. Advanced Energy Materials, 2018, 8(27): 1801840.

[55] Lin J, Peng Z, Liu Y, et al. Laser-induced porous graphene films from commercial polymers[J]. Nature Communications, 2014, 5: 5714.

[56] Ye R Q, Chyan Y, Zhang J B, et al. Laser-induced graphene formation on wood[J]. Advanced Materials, 2017, 29(37): 1702211.

[57] Chyan Y, Ye R Q, Li Y L, et al. Laser-induced graphene by multiple lasing: toward electronics on cloth, paper, and food[J]. ACS Nano, 2018, 12(3): 2176-2183.

[59] Tran T X, Choi H, Che C H, et al. Laser-induced reduction of graphene oxide by intensity-modulated line beam for supercapacitor applications[J]. ACS Applied Materials & Interfaces, 2018, 10(46): 39777-39784.

[60] Duy L X, Peng Z W, Li Y L, et al. Laser-induced graphene fibers[J]. Carbon, 2018, 126: 472-479.

[61] 苏永生, 李亮, 何宁, 等. 聚晶金刚石表面微结构的激光加工实验[J]. 中国激光, 2014, 41(8): 0803004.

[62] Li R Z, Peng R, Kihm K D, et al. High-rate in-plane micro-supercapacitors scribed onto photo paper using in situ femtolaser-reduced graphene oxide/Au nanoparticle microelectrodes[J]. Energy & Environmental Science, 2016, 9(4): 1458-1467.

[64] Zhou W P, Bai S, Ma Y, et al. Laser-direct writing of silver metal electrodes on transparent flexible substrates with high-bonding strength[J]. ACS Applied Materials & Interfaces, 2016, 8(37): 24887-24892.

[65] Mu X M, Du J W, Li Y, et al. One-step laser direct writing of boron-doped electrolyte as all-solid-state microsupercapacitors[J]. Carbon, 2019, 144: 228-234.

[67] Fu X Y, Chen D L, Liu Y, et al. Laser reduction of nitrogen-rich carbon nanoparticles@graphene oxides composites for high rate performance supercapacitors[J]. ACS Applied Nano Materials, 2018, 1(2): 777-784.

[68] Huang Y H, Zeng L, Liu C G, et al. Laser direct writing of heteroatom (N and S)-doped graphene from a polybenzimidazole ink donor on polyethylene terephthalate polymer and glass substrates[J]. Small, 2018, 14(44): 1803143.

[70] Peng Z W, Ye R Q, Mann J A, et al. Flexible boron-doped laser-induced graphene microsupercapacitors[J]. ACS Nano, 2015, 9(6): 5868-5875.

[71] Clerici F, Fontana M, Bianco S, et al. In situ MoS2 decoration of laser-induced graphene as flexible supercapacitor electrodes[J]. ACS Applied Materials & Interfaces, 2016, 8(16): 10459-10465.

[73] Zheng W J, Zhang Y, Niu K Y, et al. Selective nitrogen doping of graphene oxide by laser irradiation for enhanced hydrogen evolution activity[J]. Chemical Communications (Cambridge, England), 2018, 54(97): 13726-13729.

[74] 龙江游, 黄婷, 叶晓慧, 等. 低功率CO2激光辐照对多层石墨烯结构的影响[J]. 中国激光, 2012, 39(12): 1206001.

[75] 廖嘉宁, 王欣达, 周兴汶, 等. 飞秒激光直写铜微电极研究[J]. 中国激光, 2019, 46(10): 1002013.

[76] 王金艳, 李奇, 陈曦, 等. 全固态高重复频率244nm紫外激光器[J]. 中国激光, 2019, 46(9): 0901010.

[77] Shi H H, Jang S, Naguib H E. Freestanding laser-assisted reduced graphene oxide microribbon textile electrode fabricated on a liquid surface for supercapacitors and breath sensors[J]. ACS Applied Materials & Interfaces, 2019, 11(30): 27183-27191.

[78] Liu C L, Liang H W, Wu D, et al. Direct semiconductor laser writing of few-layer graphene polyhedra networks for flexible solid-state supercapacitor[J]. Advanced Electronic Materials, 2018, 4(7): 1800092.

[80] Mao X L, Xu J H, He X, et al. All-solid-state flexible microsupercapacitors based on reduced graphene oxide/multi-walled carbon nanotube composite electrodes[J]. Applied Surface Science, 2018, 435: 1228-1236.

[81] Li L, Zhang J B, Peng Z W, et al. High-performance pseudocapacitive microsupercapacitors from laser-induced graphene[J]. Advanced Materials, 2016, 28(5): 838-845.

[82] Feng W D, Li X, Lin S Y, et al. Enhancing the efficiency of graphene oxide reduction in low-power digital video disc drives by a simple precursor heat treatment[J]. ACS Applied Materials & Interfaces, 2019, 11(51): 48162-48171.

[83] Gao W, Singh N, Song L, et al. Direct laser writing of micro-supercapacitors on hydrated graphite oxide films[J]. Nature Nanotechnology, 2011, 6(8): 496-500.

[84] Kwon S, Yoon Y, Ahn J, et al. Facile laser fabrication of high quality graphene-based microsupercapacitors with large capacitance[J]. Carbon, 2018, 137: 136-145.

[86] Shi X Y, Zhou F, Peng J X, et al. One-step scalable fabrication of graphene-integrated micro-supercapacitors with remarkable flexibility and exceptional performance uniformity[J]. Advanced Functional Materials, 2019, 29(50): 1902860.

[87] Ye J L, Tan H B, Wu S L, et al. Direct laser writing of graphene made from chemical vapor deposition for flexible, integratable micro-supercapacitors with ultrahigh power output[J]. Advanced Materials, 2018, 30(27): 1801384.

[88] Shi Q L, Xiang Y J, Ji G H, et al. Flexible planar-integrated micro-supercapacitors from electrochemically exfoliated graphene as advanced electrodes prepared by flash foam-assisted stamp technique on paper[J]. Energy Technology, 2019, 7(11): 1900664.

[90] Xu C Y, Jiang L, Li X, et al. Miniaturized high-performance metallic 1T-phase MoS2 micro-supercapacitors fabricated by temporally shaped femtosecond pulses[J]. Nano Energy, 2020, 67: 104260.

[92] Li Q, Wang Q Z, Li L L, et al. Femtosecond laser-etched MXene microsupercapacitors with double-side configuration via arbitrary on- and through-substrate connections[J]. Advanced Energy Materials, 2020, 10(24): 2000470.

[93] Huang K C, Lin C H. S A K, et al. Laser printer patterned sacrificed layer for arbitrary design and scalable fabrication of the all-solid-state interdigitated in-planar hydrous ruthenium oxide flexible micro supercapacitors[J]. Journal of Power Sources, 2019, 417: 108-116.

[94] Zhang W L, Jiang Q, Lei Y J, et al. Wettability-driven assembly of electrochemical microsupercapacitors[J]. ACS Applied Materials & Interfaces, 2019, 11(23): 20905-20914.

[96] Jiang K Y, Baburin I A, Han P, et al. Interfacial approach toward benzene-bridged polypyrrole film-based micro-supercapacitors with ultrahigh volumetric power density[J]. Advanced Functional Materials, 2020, 30(7): 1908243.

[97] Jiang H Q, Tong L, Liu H D, et al. Graphene-metal-metastructure monolith via laser shock-induced thermochemical stitching of MOF crystals[J]. Matter, 2020, 2(6): 1535-1549.

[98] Basu A, Roy K, Sharma N, et al. CO2 laser direct written MOF-based metal-decorated and heteroatom-doped porous graphene for flexible all-solid-state microsupercapacitor with extremely high cycling stability[J]. ACS Applied Materials & Interfaces, 2016, 8(46): 31841-31848.

[100] Mu X W, Wen Q H, Ou G, et al. A current collector covering nanostructured villous oxygen-deficient NiO fabricated by rapid laser-scan for Li-O2 batteries[J]. Nano Energy, 2018, 51: 83-90.

[101] 张健, 吴锐欢, 李泽曦, 等. 激光加工中双工位加工系统的研究[J]. 中国激光, 2013, 40(10): 1003003.

Article Outline

白聪聪, 张峻豪, 高畅, 靳绪庭, 李欣, 熊伟, 闫剑锋, 张志攀, 赵扬, 曲良体. 基于激光加工的平面型微型超级电容器[J]. 中国激光, 2021, 48(2): 0202013. Congcong Bai, Junhao Zhang, Chang Gao, Xuting Jin, Xin Li, Wei Xiong, Jianfeng Yan, Zhipan Zhang, Yang Zhao, Liangti Qu. Planar Micro-Supercapacitor Based on Laser Processing[J]. Chinese Journal of Lasers, 2021, 48(2): 0202013.

![MSCs制备示意图及其电镜照片[88]](/richHtml/zgjg/2021/48/2/0202013/img_3.jpg)

![纸基MSCs的制作示意图[89]](/richHtml/zgjg/2021/48/2/0202013/img_4.jpg)

![全固态柔性MSCs制备示意图[93]](/richHtml/zgjg/2021/48/2/0202013/img_7.jpg)

![MSCs制备示意图[95]](/richHtml/zgjg/2021/48/2/0202013/img_9.jpg)

![柔性MSCs制备示意图[98]](/richHtml/zgjg/2021/48/2/0202013/img_12.jpg)