飞秒激光诱导多壁碳纳米管与金属电极连接的实验研究  下载: 1029次

下载: 1029次

Objective Carbon nanotubes (CNTs) have become an essential electronic material to replace silicon materials in the post-Moore era due to their unique electrical properties and one-dimensional nanostructures. The micro/nano electronic devices fabricated by CNTs have the advantages of small size, high speed, and low power consumption. The type of effective method to be used to achieve a reliable and effective connection between CNTs and metal electrodes has always been a difficulty and key point in the construction of CNTs electronic devices. To achieve an effective and reliable connection between CNTs and metals, a series of connection technologies have been proposed, such as metal welding, local annealing, ultrasonic welding, electron beam, and ion irradiation. However, some additional elements, such as graphitized carbon, hydrogen, and other solders, are introduced into the interface between CNTs and metal, which affects its connection performances. The process of some methods is complicated, and they required accurate positioning. Thus, an effective and reliable connection technology between CNTs and metal electrodes on a large-scale without damaging the metal electrodes or other structures is highly needed. The laser-processing technology is widely used to manufacture electronic devices with the advantages of high peak power, noncontact processing, and good controllability. Femtosecond pulse laser is considered a cold processing technology since its pulse width is less than the cooling time of the electron. It can avoid damage to the metal electrode structure caused by heat accumulation. Besides, it is an ideal high-energy beam interconnection technology. We use femtosecond pulse laser irradiation technology to realize an effective and repeatable connection between Multi-walled CNTs (MWCNTs) and different metal electrodes (Au and Ni), which provides a certain experimental basis for subsequent large-scale preparation of high-performance CNTs field-effect transistors.

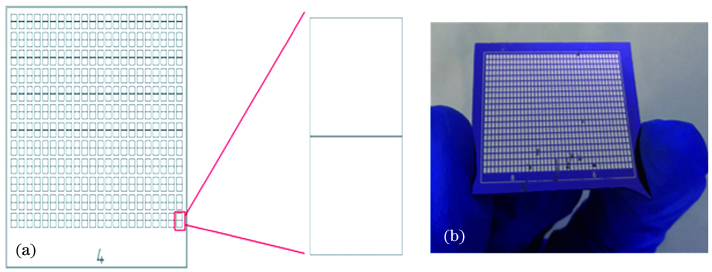

Methods In this experiment, mass concentration of 0.1 mg/mL sodium dodecyl sulfate is applied as a surfactant, and the MWCNTs powder is dispersed uniformly and stably in an aqueous solution using ultrasonic vibration. Spin coating is adopted to deposit the MWCNTs after laying electrodes. In this process, the metal electrode is the carrier of MWCNTs and test probe in the subsequent electrical performance test. Thus, the metal electrode should have a larger area for electrical performance test and smaller channel width for MWCNTs and metal contact. The morphology and size of the electrode are designed. The electrode is a rectangle of 200 μm×200 μm, and the channel's width is 8 μm. The required electrode group is obtained by photolithography, as shown in Fig. 2(a)--Fig. 2(b). Further, MWCNTs are deposited on the metal electrode by the spin coating process with a mass concentration of 0.005 mg/mL MWCNTs dispersion. In this experiment, scanning electron microscope is used to characterize the intrinsic structure, metal electrode structure, and metal morphology of MWCNTs. The electrical properties are tested using a semiconductor device analyzer.

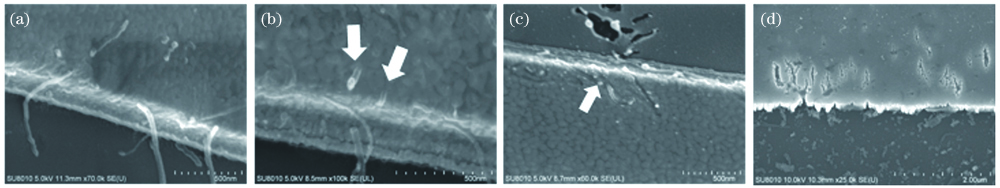

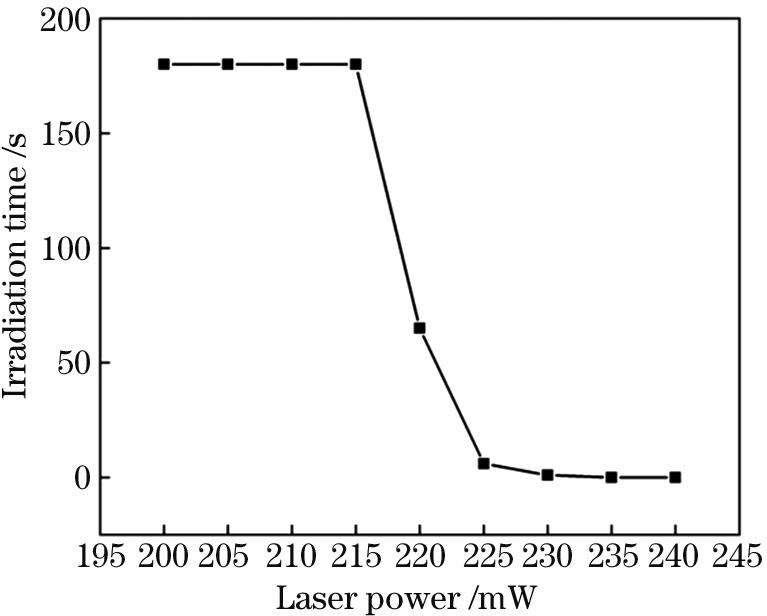

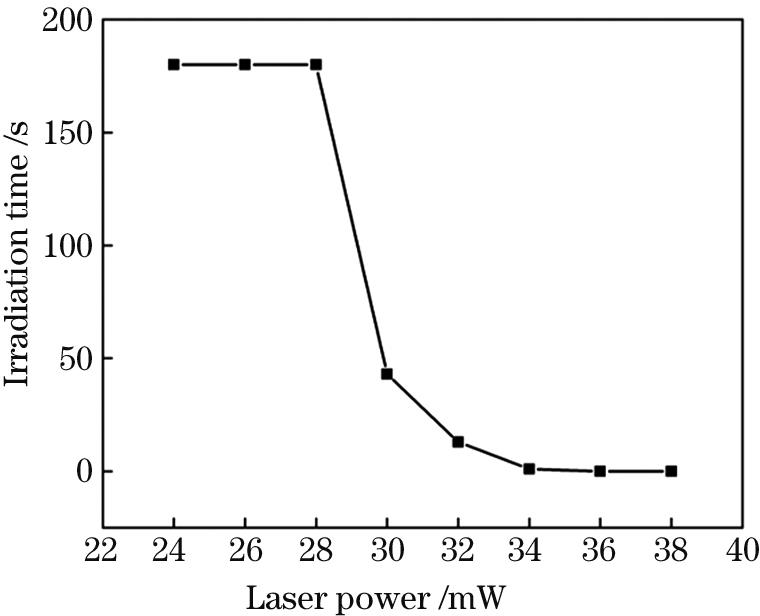

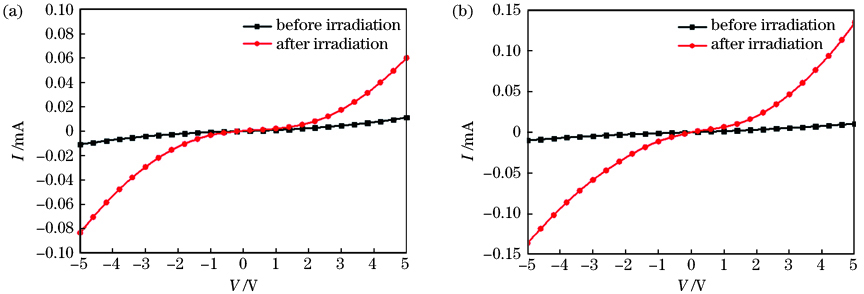

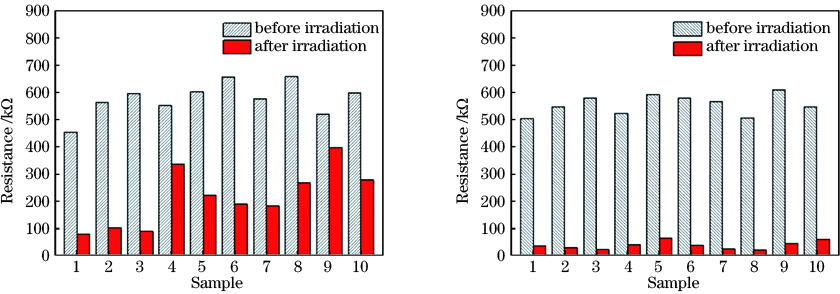

Results and Discussions Femtosecond laser irradiation technology can achieve an effective and repeatable connection between MWCNTs and metal electrodes. The results show that there is no linear relationship between the laser power and irradiation time. Considering MWCNTs and Au as examples, it can be divided into three stages. The first is the nonaction stage. In this stage, even if the laser irradiation time is continually increased, the effect on the Au surface is ignored. The second is the selective modification stage. When the laser power is increased to 220 mW and the irradiation time is set at 60 s, the local plasma enhancement effect between MWCNTs and Au surface modifies the metal surface. When laser irradiates at the Au surface, the free-electron in Au collides with the photon of laser inelastic. Then, the free-electron absorbing photon energy migrates to a high-energy level, which increases the lattice thermal shock. Further, the local area is heated and softened, and micro molten pool formed MWCNTs are “embedded” in the metal electrode, forming a good “embedded” connection (Fig. 4(b)). The Au electrode will be ablated at 65 s in 220 mW. The last stage is material removal. When the laser power increases to 235 mW, the electrode surface will be damaged and ablated in different degrees within 50 ms (Fig. 4(d)). The same state also occurred in the Ni-MWCNTs structure. The results of the electrical test show that the contact resistance between MWCNTs and Au or Ni has been greatly decreased (Fig. 9), indicating that the connection is effective and repeatable.

Conclusions The effects of processing parameters of femtosecond pulse laser, such as irradiation, time, and laser power, on the morphology of different metal electrodes and MWCNTs, are investigated experimentally. When the laser power is 220 mW, and irradiation time is 30 s, an embedded connection formed between Au and MWCNTs. When the laser power is 28 mW and the irradiation time is 30 s, the cladding connection formed between Ni and MWCNTs. Under the same laser power, as the irradiation time continues to increase, the metal electrode surface would be ablated, and the structure of the electrode would be destroyed. The MWCNTs deposited on the electrode surface would be peeled off by the laser shock wave. The contact resistance of Au-MWCNTs-Au structure is reduced from 454--658 kΩ to 78.9--397 kΩ and that of Ni-MWCNTs-Ni structure is reduced from 505--612 kΩ to 21.1--64.6 kΩ. The latter structure is reduced by an order of magnitude, verifying the effectiveness of the connection. It also show that the bonding force and wettability of metal to MWCNTs influence electronic transport before and after interconnection.

1 引言

自计算机和集成电路诞生以来,半导体工业沿着摩尔定律指出的方向飞速发展。2005年,国际半导体技术发展路线图(ITRS)委员会明确指出2020年前后硅基互补金属氧化物半导体(CMOS)技术可能达到其性能极限[1]。2008年,ITRS新兴研究材料和新兴研究器件工作组在考察所有可能的硅基CMOS替代技术后,将碳基电子学作为未来5~10年内的下一代电子技术,并在2009年将碳基纳米材料列入延续摩尔定律的未来集成电路技术中[2-3]。碳纳米管(CNTs)凭借其独特的电学性质和一维纳米结构,在众多碳基材料中脱颖而出,成为国内外科学家关注和研究的焦点[4-5]。强共价键结构使CNTs具有较高的机械稳定性和热稳定性,良好的抗电迁移能力使CNTs可承受较高的电流密度,这些特点使CNTs在场效应晶体管、新型传感器和互连导线等领域有很好的应用前景[6-9]。在实际应用中,CNTs与金属结构需要形成牢靠和稳定的接触才能保证器件的性能,因此,优化CNTs与金属电极之间的接触对提高基于CNTs器件的性能具有重要意义[10-12]。

为了实现CNTs与金属电极之间有效且可靠的连接,国内外研究学者提出了一系列连接技术,如金属焊接法[13]、局部退火法[14-16]、超声焊接法[17-18]、电子束或离子束辐照技术[19-20]。但这些技术主要是在CNTs与金属电极界面上涂覆金属焊料[21]、石墨化碳[22]、碳化氢[23]、Au-C[24]等焊料,焊料在局部能量的作用下软化或融化,使CNTs与金属电极产生良好的连接。上述连接工艺都比较复杂,且需要精准定位。此外,焊料元素的引入会对连接性能产生一定的影响。超声焊接法虽然能很好地实现CNTs与多种金属电极之间牢靠的连接,但其超声头与金属电极需要接触传递振动,会对金属电极表面结构造成不可逆转的损伤。因此,亟需寻求一种工艺简单、且需在不破坏金属电极或其他结构的前提下能大规模实现的连接技术。激光加工技术具有峰值功率高、非接触加工、可控性好等优点,被广泛应用于电子器件的制造中。其中,飞秒脉冲激光的脉宽小于电子冷却时间,被认为是一种冷加工技术,可以很好地避免热累积对金属电极结构的破坏[25],是一种理想的高能束互连技术。

本文利用飞秒脉冲激光辐照方法系统地研究了激光辐照时长等激光参数对多壁碳纳管(MWCNTs)形貌、金属电极结构的影响规律,实现了MWCNTs与不同金属电极(金、镍)之间良好的连接,并通过电学性能测试实验验证了MWCNTs与金属电极之间连接的有效性及可重复性。

2 实验装置和方法

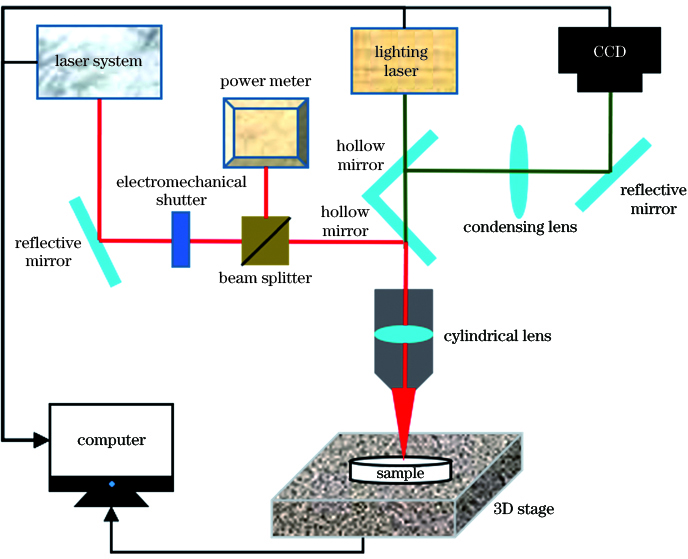

作为飞秒脉冲激光诱导CNTs-金属电极连接实验中的关键部件,飞秒脉冲激光器的性能参数是决定连接效果的关键。实验选用的激光器为美国Newport Corporation公司生产的SPFIRE ACE-100F1K型激光器,其重复频率为1 kHz、脉冲宽度为120 fs、中心波长为800 nm,具体实验装置如

实验采用的MWCNTs粉末采购于中国南京先丰公司,标称纯度大于70%,直径为30~50 nm,长度为5~10 μm。MWCNTs分散的均匀性和稳定性直接影响到MWCNTs实际应用的性能,实验首先用质量浓度为0.1 mg/mL的十二烷基硫酸钠(SDS)作为表面活性剂,然后结合超声振动实现MWCNTs在水溶液中的均匀稳定分散。为了直观观测到MWCNTs和金属之间的接触情况,先利用光刻技术铺设电极,再用旋涂工艺沉积MWCNTs。该过程中金属电极不仅是MWCNTs的载体,也是后续电学性能测试时测试探针的载体,因此金属电极需要具备较大的面积(大于100 μm×100 μm)和较小的沟道宽度(小于10 μm),以实现MWCNTs和金属电极、探针与金属电极的接触。同时,还需要考虑电极尺寸的影响。电极太厚会使光刻过程中部分图形无法从表面剥离,电极太薄会使MWCNTs难以埋入金属电极中。针对上述要求,设计出的矩形电极形貌如

图 2. 光刻工艺制备的电极。(a)电极图案;(b)电极矩阵的实物图

Fig. 2. Electrodes prepared by photolithography process. (a) Electrode pattern; (b) physical image of the electrode matrix

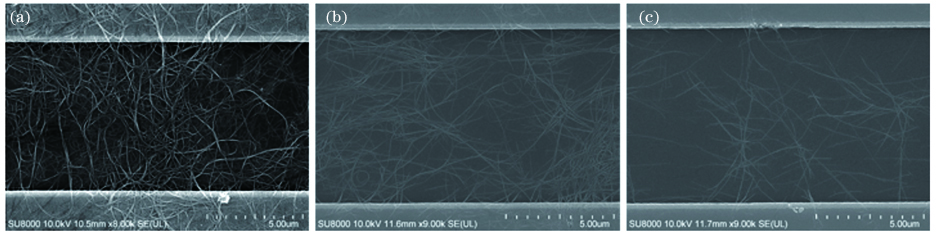

铺设好金属电极后,采用旋涂工艺将MWCNTs沉积到电极上,使MWCNTs和金属电极之间形成物理接触。MWCNTs的质量浓度决定了电极上沉积MWCNTs的密度和数量,当MWCNTs的质量浓度过低时,MWCNTs沉积在金属边缘处的概率较低,导致后续连接和观测困难;当MWCNTs的质量浓度过高时,沉积在金属电极上的MWCNTs直接形成致密薄膜,且会产生多层重叠现象,阻碍飞秒激光辐照到金属表面,影响实验结果。因此对不同质量浓度MWCNTs分散液的沉积效果进行了对比实验,结果如

图 3. 不同质量浓度的MWCNTs溶液沉积效果图。(a) 0.03 mg/mL;(b) 0.01 mg/mL;(c) 0.005 mg/mL

Fig. 3. Deposition effect images of the MWCNTs solution with different mass concentrations. (a) 0.03 mg/mL; (b) 0.01 mg/mL; (c) 0.005 mg/mL

3 实验结果及分析

3.1 Au电极与MWCNTs的连接

飞秒脉冲激光诱导MWCNTs与金属电极之间连接的效果,与激光参数(如激光辐照方式、激光功率、辐照时长)有密切联系,为了简化激光参数的变化对实验结果的影响,采用定点辐照方式进行连接实验。定点辐照是激光和样品保持相对静止,以固定的激光功率和时间辐照样品,使MWCNTs与金属电极连接处的形貌发生变化。

图 4. 不同辐照时长下MWCNTs-Au电极的SEM图像。(a) 30 s;(b) 60 s;(c) 61 s;(d) 65 s

Fig. 4. SEM images of the MWCNTs-Au electrode at different irradiation time. (a) 30 s; (b) 60 s; (c) 61 s; (d) 65 s

从

图 5. 烧蚀Au基底时辐照时长随激光功率的变化曲线

Fig. 5. Variation curve of the irradiation time with laser power when ablating Au substrate

3.2 Ni电极与MWCNTs的连接

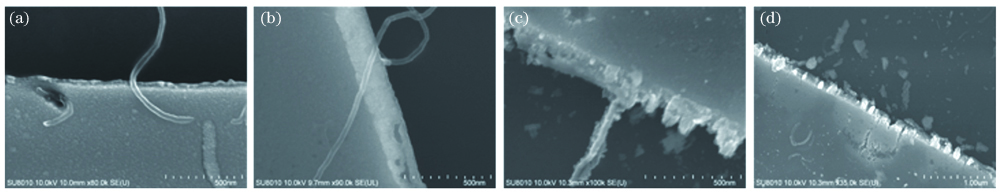

为了验证MWCNTs能够与不同金属电极产生连接,采用与3.1小节相同的光刻工艺,制备了厚度为100 nm的金属Ni电极,

图 6. 不同辐照时长下MWCNTs-Ni电极的SEM图像。(a) 30 s;(b) 60 s;(c) 61 s;(d) 65 s

Fig. 6. SEM images of the MWCNTs-Ni electrode at different irradiation time. (a) 30 s; (b) 60 s; (c) 61 s; (d) 65 s

图 7. 烧蚀Ni基底时辐照时长随激光功率变化曲线

Fig. 7. Variation curve of the irradiation time with laser power when ablating Ni substrate

MWCNTs与金属电极的位置[26-27]、金属的润湿特性及碳原子的结合力[28-29]对两者的连接形式有很大影响,且MWCNTs管壁上的强共价键会在激光作用下被破坏,形成空位与缺陷,而空位与缺陷容易在外界能量作用下与金属电极之间形成牢靠的共价键[30-31]。在飞秒脉冲激光辐照下,金属电极与MWCNTs相互接触的区域产生了局部近场增强效应,金属Ni电极表层的自由电子吸收激光能量,形成超热电子。超热电子迅速向四周扩散,通过电子-声子耦合将能量传递给Ni原子,使Ni原子具有较大的动能。与此同时,MWCNTs与金属电极形成了端点接触,其MWCNTs端口的碳原子环对Ni原子产生的吸附力[32],使Ni原子向MWCNTs表面迁移,对MWCNTs形成了包覆。这种连接形式最直接的表现为金属电极与MWCNT连接处的MWCNTs直径比未发生连接的MWCNT直径略大。Ni金属d轨道上有不成对的电子与碳原子2p轨道在外界能量的作用下可进行杂化,形成较强(每个Ni原子的结合能可达2.0 eV)的共价连接[33]。Au金属对CNTs的润湿性比Ni金属对CNTs的润湿性差,因此Au金属在CNTs上不能形成金属层,只能形成一个个孤立的金属岛[33],且Au金属d轨道完全被电子占据,很难通过杂化与CNTs之间形成较强的(每个Au原子的结合能小于1.0 eV)的连接。因此当飞秒脉冲激光与Au电极相互作用时,MWCNTs与Au电极之间产生的近场增强效应使与MWCNTs接触的Au电极表面迅速升温软化,将MWCNT的一端或整根MWCNT埋入Au电极,形成嵌入式连接。

3.3 电学性能测试

为了研究MWCNTs与金属电极被激光辐照前后的电学性能变化,分别测试了MWCNTs与Au、Ni电极结构中两电极间两点的伏安特性曲线及相应的界面电阻。对于金属-MWCNTs-金属结构,其总电阻R由金属电极本征电阻R1、MWCNTs本征电阻R2、MWCNTs和金属电极接触电阻R3组成。金属电极和MWCNTs都是较好的导体,其激光辐照前后的电阻变化可忽略不计,因此辐照前后的电阻变化量ΔR约等于ΔR3。

图 8. 同一样品辐照前后的I-V曲线。(a)Au-MWCNTs;(b)Ni-MWCNTs

Fig. 8. I-V curves of the same sample before and after irradiation. (a) Au-MWCNTs; (b) Ni-MWCNTs

为了更具体地对比辐照前后金属电极与MWCNTs界面接触电阻的变化,分别给出了10组Au-MWCNTs和Ni-MWCNTs辐照前后的电阻变化结果,如

图 9. 不同样品辐照前后的界面接触电阻变化曲线。(a)Au-MWCNTs;(b)Ni-MWCNTs

Fig. 9. Change curves of the interface contact resistance before and after irradiation for different samples. (a) Au-MWCNTs; (b) Ni-MWCNTs

4 结论

通过实验研究了飞秒脉冲激光的加工参数如辐照时长、激光功率对不同金属电极与MWCNTs连接的影响,通过观测MWCNTs本征结构、MWCNTs-金属电极之间的相貌变化、金属电极边缘结构变化确定了最佳连接工艺参数。当激光功率为220 mW,辐照时长为30 s时,Au电极与MWCNTs之间形成嵌入式连接;当激光功率为28 mW,辐照时长为30 s时,Ni电极与MWCNTs形成包覆式连接。在相同激光功率下继续增加辐照时长,会使金属电极表面发生烧蚀,电极边缘结构被破坏,沉积在电极表面的MWCNTs也会在激光的冲击波下被剥离,无法形成良好的连接。后续的电学性能测试结果表明,不同样品的电阻下降趋势基本相同,验证了该连接的可重复性。Au-MWCNTs-Au结构的接触电阻从454~658 kΩ下降到78.9~397 kΩ,Ni-MWCNTs-Ni结构的接触电阻从505~612 kΩ下降到21.1~64.6 kΩ,验证了该连接的有效性,也表明金属对MWCNTs的结合力及润湿性对其互连前后的电子运输有一定程度的影响。

[3] Waldrop M M. The chips are down for Moore's law[J]. Nature, 2016, 530(7589): 144-147.

[4] 吴雪峰, 尹海亮, 李强. 飞秒激光加工碳纳米管薄膜试验研究[J]. 中国激光, 2019, 46(9): 0902002.

[7] 杨立军, 崔健磊, 王扬, 等. 碳纳米管互连技术新进展[J]. 新型炭材料, 2016, 31(1): 1-17.

[8] Avouris P, Chen Z H, Perebeinos V. Carbon-based electronics[J]. Nature Nanotechnology, 2007, 2(10): 605-615.

[17] Chen CX, Yan L J, Kong E S W, et al. Ultrasonic nanowelding of carbon nanotubes to metal electrodes[J]. Nanotechnology, 2006, 17(9): 2192-2197.

[19] Bachtold A, Henny M, Terrier C, et al. Contacting carbon nanotubes selectively with low-ohmic contacts for four-probe electric measurements[J]. Applied Physics Letters, 1998, 73(2): 274-276.

[24] Yu M. Strength andbreaking mechanism of multiwalled carbon nanotubes under tensile load[J]. Science, 2000, 287(5453): 637-640.

[25] 杨建军. 飞秒激光超精细“冷”加工技术及其应用(I)[J]. 激光与光电子学进展, 2004, 41(3): 42-52, 57.

[31] Maiti A, Ricca A. Metal-nanotube interactions: binding energies and wetting properties[J]. Chemical Physics Letters, 2004, 395(1/2/3): 7-11.

梅欢欢, 崔健磊, 程杨, 何小桥, 梅雪松. 飞秒激光诱导多壁碳纳米管与金属电极连接的实验研究[J]. 中国激光, 2021, 48(8): 0802019. Huanhuan Mei, Jianlei Cui, Yang Cheng, Xiaoqiao He, Xuesong Mei. Experimental Study on Connection Between Multiwalled Carbon Nanotubes and Metal Electrodes Under Femtosecond Laser Irradiation[J]. Chinese Journal of Lasers, 2021, 48(8): 0802019.