光学学报, 2020, 40 (13): 1322001, 网络出版: 2020-07-09

碳化硅晶圆的快速高质量复合加工方法  下载: 1074次

下载: 1074次

Fast and High Quality Composite Processing Method for Silicon Carbide Wafers

光学制造 碳化硅晶圆 磁流变抛光 环抛 表面质量 亚表面损伤 optical fabrication silicon carbide wafer magnetorheological finishing ring polishing surface quality subsurface damage

摘要

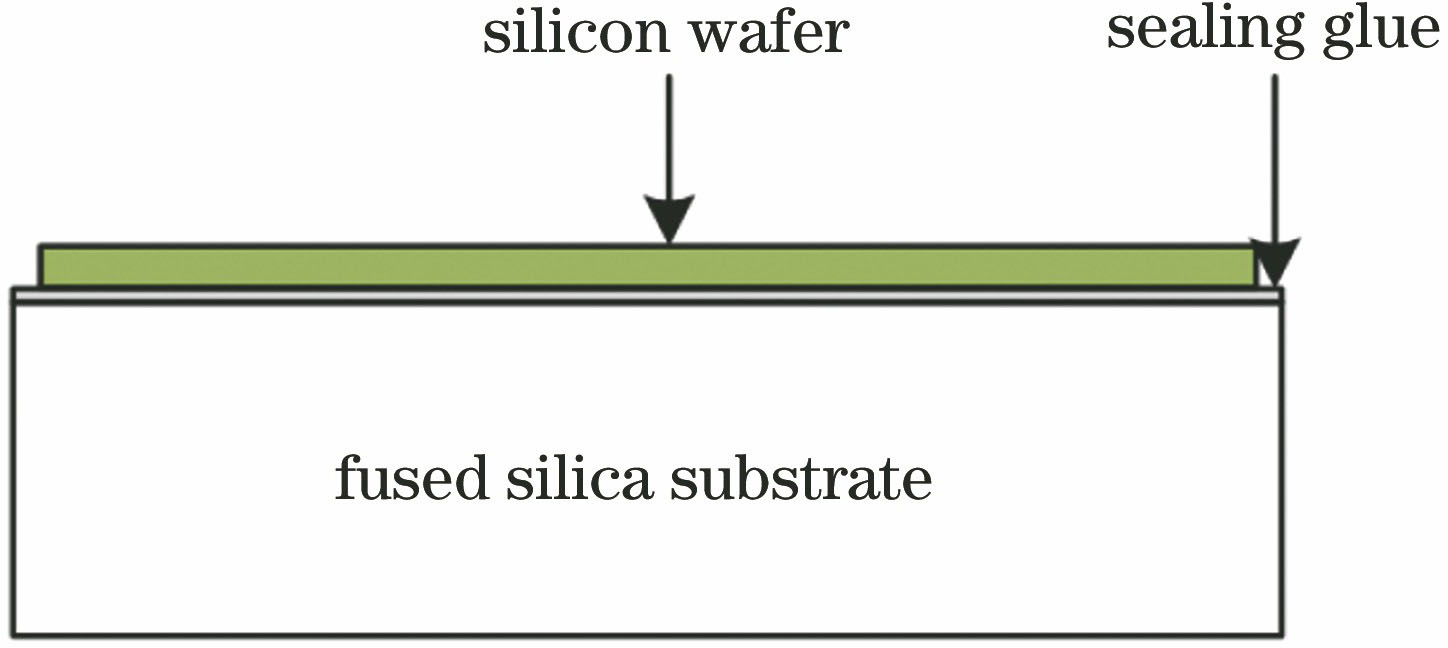

为了提升单晶碳化硅(SiC)材料的抛光效率及表面质量,提出了将传统抛光与磁流变抛光(MRF)相结合的新方法,并对一块直径为100 mm的单晶SiC晶圆进行实际加工。首先,采用环抛技术将单晶SiC晶圆表面粗糙度快速加工至0.6 nm左右;然后,通过配制特殊的磁流变抛光液,采用磁流变抛光技术对晶圆进行35 min快速均匀抛光,改善了SiC晶圆表面的缺陷,消除了晶圆亚表面损伤;最后,采用纳米金刚石抛光液,通过环抛对SiC晶圆进行精抛光,获得了粗糙度为0.327 nm的高表面质量单晶SiC晶圆。该方法将单晶SiC晶圆的加工时间缩短了约7 h,有利于提升SiC晶圆的加工效率、精度及质量。

Abstract

In order to improve the polishing efficiency and surface quality of single-crystal silicon carbide (SiC) materials, we propose a new method based on traditional polishing combined with magnetorheological finishing (MRF), which is used for the practical fabrication of a single-crystal SiC wafer with a diameter of 100 mm. First, the surface roughness of the single-crystal SiC wafer is rapidly processed to about 0.6 nm by the ring polishing method. Then, the wafer uniform polishing for 35 min with MRF is adopted to improve the defects on the surface of SiC wafer and eliminate the subsurface damage of the wafer via the preparation of a special magnetorheological polishing fluid. Finally, the ring polishing is adopted to finely polish the SiC wafer with the nano-diamond polishing fluid and a high surface quality single-crystal SiC wafer with roughness of 0.327 nm is obtained. The method proposed here reduces the fabrication time by about 7 h and is helpful to improve the fabrication efficiency, precision and surface quality of SiC wafers.

杨超, 李福坤, 任婷, 魏源松, 白杨. 碳化硅晶圆的快速高质量复合加工方法[J]. 光学学报, 2020, 40(13): 1322001. Chao Yang, Fukun Li, Ting Ren, Yuansong Wei, Yang Bai. Fast and High Quality Composite Processing Method for Silicon Carbide Wafers[J]. Acta Optica Sinica, 2020, 40(13): 1322001.