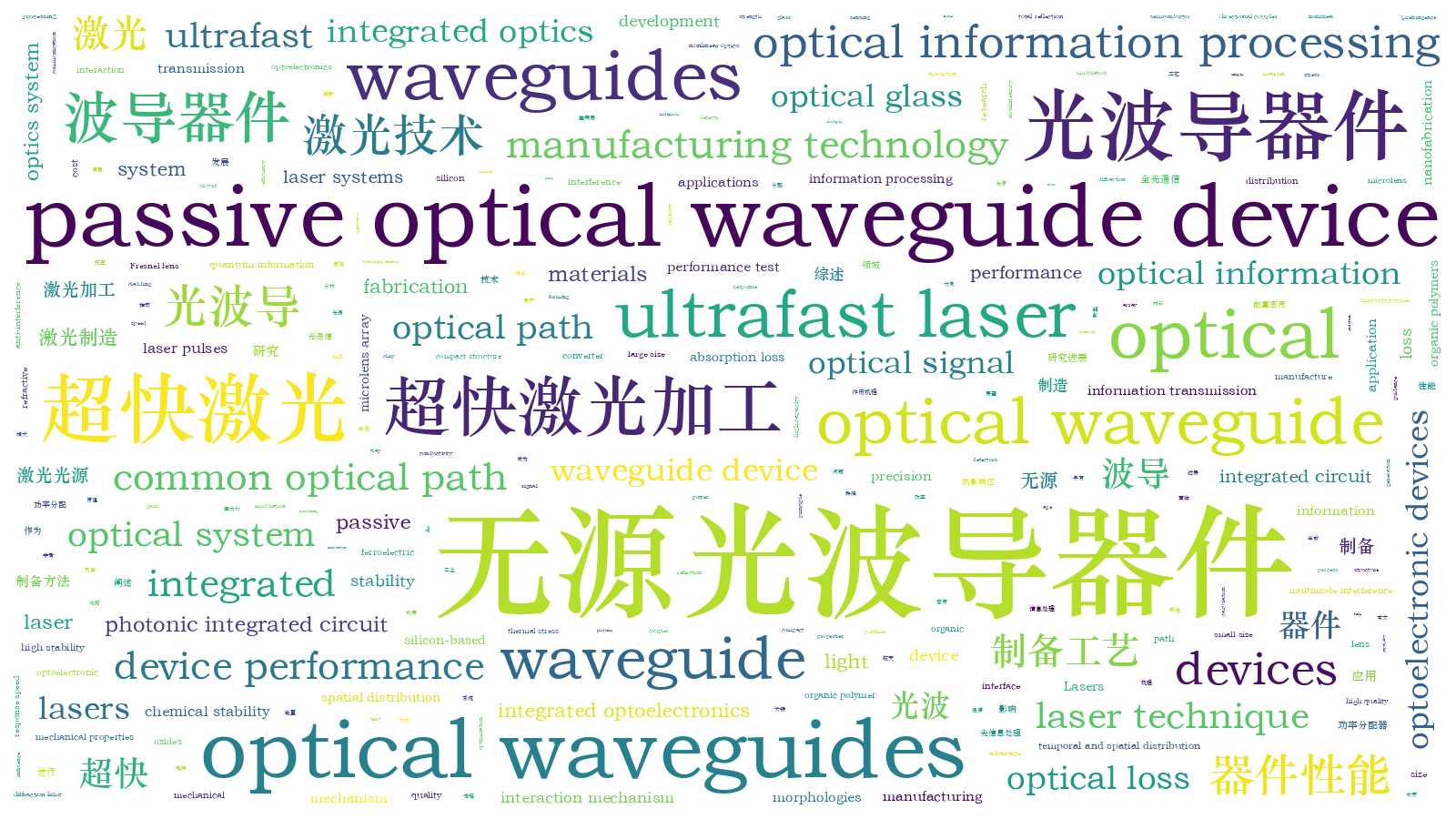

超快激光在无源光波导器件制造中的应用综述  下载: 1832次

下载: 1832次

Significance With the development of aeronautics, astronautics, communication, and instrument fields, conventional optical and electrical systems can hardly meet the demand for information transmission with high capacity and rate. Integrated optics system gradually develops under this historical circumstance. Its superiority is that optical devices with different functions can be integrated into a limited area, and the optical signal can be transmitted and processed. Comparing with a conventional optical system, an integrated optics system has the superiorities of small size, compact structure, high stability, and strong anti-interference capability. The optical waveguide device is the most basic unit within the integrated optics system. Its principle is that total reflection takes place at the media interface when light transmits in media with different refractive indexes, and light can be trapped in the microstructures. A channel forms correspondingly, in which light is capable of transmitting along a specific direction. Optical waveguide devices can trap and guide light and provide extra functions such as nonlinearity and active gain. Besides, optical waveguide devices can cooperate with other components in the integrated optics system, forming a photonic integrated circuit with various functions. Therefore, the performance of the optical waveguide device has a considerable influence on the performance of an integrated optics system. The development of manufacturing technology for optical waveguide devices with high quality and precision of great importance for the innovation of photocommunication, optical information processing, optical calculation, and optical sensing.

Optical waveguide devices can be divided into passive and active devices. The former devices are the basic units of integrated optoelectronics, and they are more widely used. Passive waveguides are mainly fabricated using semiconductors and organic polymers. There are three types of semiconductor waveguides, listed as silicon-based waveguides, III-IV group compounds waveguides, and ferroelectric oxides waveguides. Specifically, silicon-based waveguides have the advantages of good heat conductivity, chemical stability, mechanical strength, and low absorption loss. However, there is a large difference between the refractive indexes of cladding and core. The advantage of III-IV group compounds waveguides is that they can be integrated on the same chip with active devices. However, the large transmission loss and cost limit their further application. The advantages of ferroelectric oxides waveguides are large electrooptic coefficient, high response speed, and excellent heat and chemical stability. However, they are still troubled by high cost and large size. In terms of organic polymer waveguides, they are characterized by low optical loss and birefringence, high thermooptical and electrooptical coefficients as well as simple fabrication techniques. Unfortunately, they age easily, which is unfavorable for improving the device stability.

In 1996, Davis K M manufactured an optical waveguide with optical glass for the first time. In the following decades, with the development of ultrafast laser systems and optimization of manufacturing technology, researchers from home and abroad have successfully manufactured various optical waveguides in different materials. Although several remarkable advances have been made in improving device performance, the industrial fields are still troubled with several problems, such as non-negligible machining defects and transmission loss. Hence, it is of great significance to summarize the existing research to guide the future development of manufacturing technology for passive waveguide devices.

Progress The interaction mechanism between laser and waveguide materials is first explained. On these bases, the application of ultrafast laser in the manufacture of optical path converter is firstly interpreted. As a common optical path converter, the morphologies of curved waveguides before or during the performance test are shown (

Conclusions and Prospect Since the 1990s, a large number of theoretical and experimental studies have pointed out that ultrafast lasers are effective tools to fabricate various passive optical waveguides in dielectrics and polymers. Especially in recent years, based on the investigation of the interaction mechanism between ultrafast lasers and different waveguide materials, researchers have achieved the fabrication of passive waveguides with multiple structures and excellent performance by adjusting the temporal and spatial distribution of laser pulses. The fabrication techniques are optimized, and the process is simplified. To further improve the fabrication quality and precision, there are still several existing problems that need to be solved from the aspects of mechanism and techniques. For instance, the quantitative analysis and precise modulation of the spatial distribution of thermal stress induced by ultrafast lasers within the same material as well as the interface between different materials and the controllable fabrication of different materials with a precision that exceeds the diffraction limit.

Nowadays, integrated optoelectronic devices are developing toward multifunctions and high integrated levels, which raises great challenges for passive optical waveguides. On the one side, their volumes need to be minimized, and production efficiency needs to be improved further. On the other side, their applications are not only limited to treating light signals, but also integrated with active optical waveguides, such as lasers, modulators, and detectors to construct new-generation optoelectronic devices. Besides, novel materials such as graphene have been used to fabricate passive waveguides. To deal with these challenges, the transient evolution mechanisms of light, heat, electrical, and mechanical properties of different waveguide materials irradiated by ultrafast lasers should be investigated deeply. Under the guidance of theoretical studies, nanofabrication and parallel fabrication technologies can be developed that are beneficial for extending the application of ultrafast lasers in modern industrial fields, such as integrated optics, quantum information, and nonlinear optics.

丁烨, 李强, 李靖怡, 王联甫, 杨立军. 超快激光在无源光波导器件制造中的应用综述[J]. 中国激光, 2021, 48(8): 0802020. Ye Ding, Qiang Li, Jingyi Li, Lianfu Wang, Lijun Yang. Application of Ultrafast Lasers in the Manufacture of Passive Optical Waveguide Devices: A Review[J]. Chinese Journal of Lasers, 2021, 48(8): 0802020.