深冷激光喷丸对TC6钛合金阻尼特性及振动疲劳寿命的影响  下载: 920次

下载: 920次

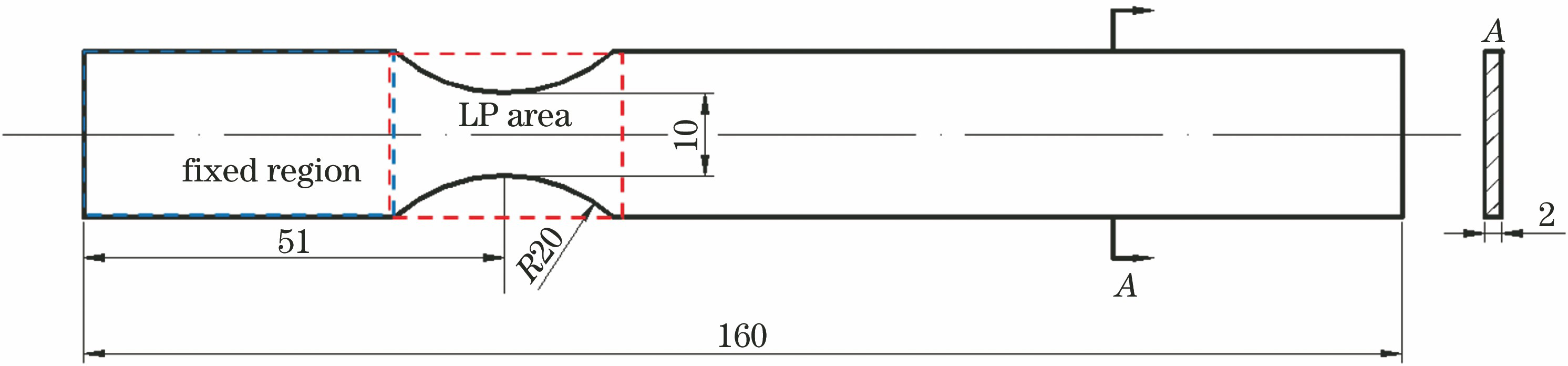

黄宇, 周建忠, 李京, 田绪亮, 孟宪凯, 黄舒. 深冷激光喷丸对TC6钛合金阻尼特性及振动疲劳寿命的影响[J]. 中国激光, 2020, 47(4): 0402011.

Huang Yu, Zhou Jianzhong, Li Jing, Tian Xuliang, Meng Xiankai, Huang Shu. Effects of Cryogenic Laser Peening on Damping Characteristics and Vibration Fatigue Life of TC6 Titanium Alloy[J]. Chinese Journal of Lasers, 2020, 47(4): 0402011.

[1] 徐媛, 向文丽, 杨红斌, 等. TC6钛合金动态断裂机制[J]. 稀有金属材料与工程, 2015, 44(8): 1924-1927.

Xu Y, Xiang W L, Yang H B, et al. Dynamic fracture mechanism of TC6 titanium alloy with binary morphologies[J]. Rare Metal Materials and Engineering, 2015, 44(8): 1924-1927.

[2] 李学雄, 夏长清, 戚延龄, 等. TC6钛合金的高温拉伸蠕变行为研究[J]. 稀有金属材料与工程, 2013, 42(9): 1901-1904.

Li X X, Xia C Q, Qi Y L, et al. Tensilecreep behavior at high temperature of TC6 alloy[J]. Rare Metal Materials and Engineering, 2013, 42(9): 1901-1904.

[3] Lalanne C. Mechanical vibration and shock analysis: volume 3: random vibration[J]. Caries Research, 2003, 37(2): 125-129.

[4] Zhou J Z, Li J, Huang S, et al. Influence of cryogenic treatment prior to laser peening on mechanical properties and microstructural characteristics of TC6 titanium alloy[J]. Materials Science and Engineering: A, 2018, 718: 207-215.

[5] Fabbro R, Fournier J, Ballard P, et al. Physical study of laser-produced plasma in confined geometry[J]. Journal of Applied Physics, 1990, 68(2): 775-784.

[6] Chu J P, Rigsbee J M. Bana G, et al. Laser-shock processing effects on surface microstructure and mechanical properties of low carbon steel[J]. Materials Science and Engineering: A, 1999, 260(1/2): 260-268.

[8] 田绪亮, 周建忠, 李京, 等. 深冷激光喷丸强化对2024-T351铝合金微观组织的影响[J]. 中国激光, 2019, 46(9): 0902004.

[9] 何卫锋, 李应红, 李启鹏, 等. LSP提高TC6钛合金振动疲劳性能及强化机理研究[J]. 稀有金属材料与工程, 2013, 42(8): 1643-1648.

He W F, Li Y H, Li Q P, et al. Vibration fatigue performance and strengthening mechanism of TC6 titanium alloy by laser shock peening[J]. Rare Metal Materials and Engineering, 2013, 42(8): 1643-1648.

[10] Ye C, Suslov S, Lin D, et al. Cryogenic ultrahigh strain rate deformation induced hybrid nanotwinned microstructure for high strength and high ductility[J]. Journal of Applied Physics, 2014, 115(21): 213519.

[11] Hu J, Shi Y N, Sauvage X, et al. Grain boundary stability governs hardening and softening in extremely fine nanograined metals[J]. Science, 2017, 355(6331): 1292-1296.

[12] 姚起杭, 姚军. 工程结构的振动疲劳问题[J]. 应用力学学报, 2006, 23(1): 12-15.

Yao Q H, Yao J. Vibration fatigue in engineering structures[J]. Chinese Journal of Applied Mechanics, 2006, 23(1): 12-15.

[14] Granato A, Lücke K. Theory of mechanical damping due to dislocations[J]. Journal of Applied Physics, 1956, 27(6): 583-593.

[15] Nishiyama K, Matsui R, Ikeda Y, et al. Damping properties of a sintered Mg-Cu-Mn alloy[J]. Journal of Alloys and Compounds, 2003, 355(1/2): 22-25.

[16] González-Martínez R, Göken J, Letzig D, et al. Influence of aging on damping of the magnesium-aluminium-zinc series[J]. Journal of Alloys and Compounds, 2007, 437(1/2): 127-132.

[17] Watanabe H, Sasakura Y, Ikeo N, et al. Effect of deformation twins on damping capacity in extruded pure magnesium[J]. Journal of Alloys and Compounds, 2015, 626: 60-64.

[18] Cui Y J, Li Y P, Sun S H, et al. Enhanced damping capacity of magnesium alloys by tensile twin boundaries[J]. Scripta Materialia, 2015, 101: 8-11.

[19] Picu R C, Majorell A. Mechanical behavior of Ti-6Al-4V at high and moderate temperatures: Part II: constitutive modeling[J]. Materials Science and Engineering: A, 2002, 326(2): 306-316.

[20] Zerilli F J. Dislocation mechanics-based constitutive equations[J]. Metallurgical and Materials Transactions A, 2004, 35(9): 2547-2555.

[21] Ye C, Suslov S, Lin D, et al. Microstructure and mechanical properties of copper subjected to cryogenic laser shock peening[J]. Journal of Applied Physics, 2011, 110(8): 083504.

[22] Cui Y J, Li J X, Li Y P, et al. Damping capacity of pre-compressed magnesium alloys after annealing[J]. Materials Science and Engineering: A, 2017, 708: 104-109.

[23] Somekawa H, Watanabe H, Basha D A, et al. Effect of twin boundary segregation on damping properties in magnesium alloy[J]. Scripta Materialia, 2017, 129: 35-38.

[24] Lu J Z, Wu L J, Sun G F, et al. Microstructural response and grain refinement mechanism of commercially pure titanium subjected to multiple laser shock peening impacts[J]. Acta Materialia, 2017, 127: 252-266.

[25] Saren A, Ullakko K. Dynamic twinning stress and viscous-like damping of twin boundary motion in magnetic shape memory alloy Ni-Mn-Ga[J]. Scripta Materialia, 2017, 139: 126-129.

[26] Li J, Zhou J Z, Feng A X, et al. Investigation on mechanical properties and microstructural evolution of TC6 titanium alloy subjected to laser peening at cryogenic temperature[J]. Materials Science and Engineering: A, 2018, 734: 291-298.

黄宇, 周建忠, 李京, 田绪亮, 孟宪凯, 黄舒. 深冷激光喷丸对TC6钛合金阻尼特性及振动疲劳寿命的影响[J]. 中国激光, 2020, 47(4): 0402011. Huang Yu, Zhou Jianzhong, Li Jing, Tian Xuliang, Meng Xiankai, Huang Shu. Effects of Cryogenic Laser Peening on Damping Characteristics and Vibration Fatigue Life of TC6 Titanium Alloy[J]. Chinese Journal of Lasers, 2020, 47(4): 0402011.