预热温度对激光熔凝RuT300温度场的影响规律  下载: 1033次

下载: 1033次

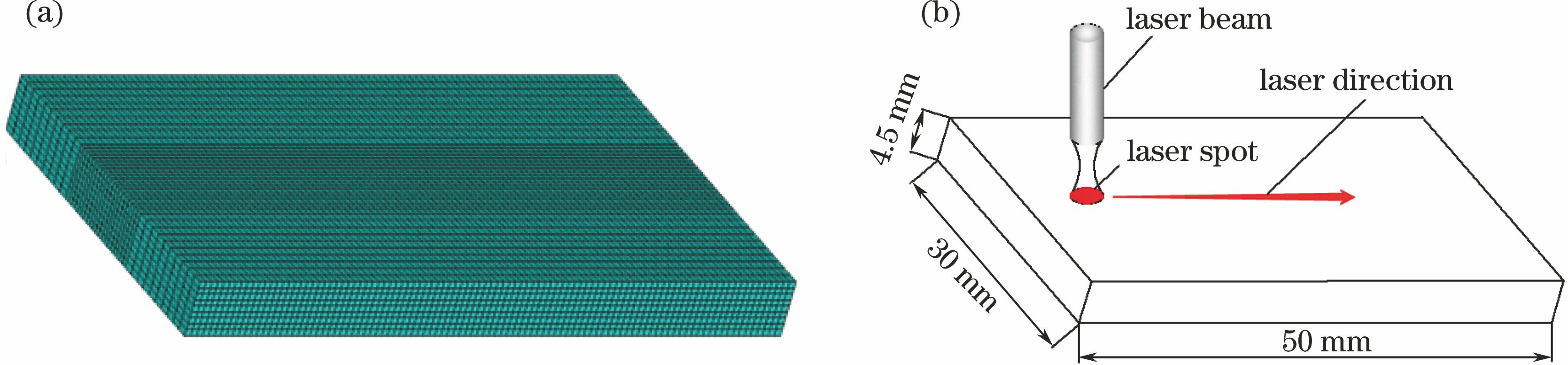

庞铭, 张啸寒, 刘光, 谭雯丹, 付威, 江国业. 预热温度对激光熔凝RuT300温度场的影响规律[J]. 激光与光电子学进展, 2019, 56(7): 071601.

Ming Pang, Xiaohan Zhang, Guang Liu, Wendan Tan, Wei Fu, Guoye Jiang. Effect of Preheating Temperature on Temperature Field of Laser Melting RuT300[J]. Laser & Optoelectronics Progress, 2019, 56(7): 071601.

[1] 张玉申. 高功率密度柴油机及其关键技术[J]. 车用发动机, 2004( 3): 5- 7, 11.

Zhang YS. High power density diesel engine and its key technologies[J]. Vehicle Engine, 2004( 3): 5- 7,11.

[2] 武岳, 李建平, 张延京, 等. 热处理工艺对RuT300蠕墨铸铁力学性能与导热性能的影响[J]. 材料热处理学报, 2017, 38(2): 143-151.

[3] 张馨心, 张国伟, 徐宏. RuT300蠕墨铸铁熔炼工艺研究[J]. 铸造技术, 2012, 33(10): 1200-1202.

[5] 李炳华, 杜欣. 蠕墨铸铁在柴油机部件上的应用[J]. 国外机车车辆工艺, 2001( 2): 1- 6,8.

Li BH, DuX. Application of CGI in the parts and components of diesel engine[J]. Foreign Locomotive & Rolling Stock Technology, 2001( 2): 1- 6,8.

[6] 伊鹏, 刘衍聪, 石永军, 等. 铸铁表面激光熔凝行为及温度场数值模拟[J]. 焊接学报, 2011, 32(8): 81-84,117.

[7] 王维, 刘奇, 杨光, 等. 钛合金激光熔凝熔池流场及温度场的数值模拟[J]. 应用激光, 2014, 34(5): 389-394.

[8] 张春燕, 杨武, 马超. 激光熔凝稀土镁合金温度场的数值模拟及其耐蚀性能[J]. 热加工工艺, 2017, 46(2): 143-147, 154.

[9] 韩涛, 王勇. CK45钢激光熔凝有限元模拟[J]. 热加工工艺, 2007, 36(16): 80-83.

[10] 闫世兴, 董世运, 徐滨士, 等. 预热温度对灰铸铁表面激光熔覆镍基涂层组织与性能的影响[J]. 材料工程, 2015, 43(1): 30-36.

[11] 丁林. 预热温度对激光熔覆Co基合金数值模拟的影响[J]. 南阳理工学院学报, 2013, 5(3): 95-100.

[12] 张群兵, 牛靖, 赵鹏飞, 等. 36(4): 87-[J]. . 预热温度对12Cr10Co3W2Mo耐热钢焊接冷裂纹敏感性的影响. 焊接学报, 2015, 91: 117-118.

Zhang QB, NiuJ, Zhao PF, et al. Influence of preheating temperature on cold cracking sensitivity of 12Cr10Co3W2Mo heat resistant steel[J]. Transactions of the China Welding Institution, 2015, 36(4): 87-91, 117- 118.

[13] 李美艳, 蔡春波, 韩彬, 等. 预热对激光熔覆陶瓷涂层温度场和应力场影响[J]. 材料热处理学报, 2015, 36(12): 197-203.

[14] 陈智, 焦向东, 罗雨, 等. 基于SYSWELD的预热温度对焊接热输入影响的有限元模拟[J]. 热加工工艺, 2014, 43(15): 164-166.

[15] 席明哲, 虞钢. 连续移动三维瞬态激光熔池温度场数值模拟[J]. 中国激光, 2004, 31(12): 1527-1532.

[16] 张哲, 韩彬, 王勇, 等. 工件形状对激光相变硬化温度场和应力场的影响[J]. 中国激光, 2012, 39(8): 0803001.

[18] 谭雯丹, 庞铭, 江国业, 等. 高强化柴油机气门座激光相变硬化温度场数值模拟[J]. 激光与光电子学进展, 2018, 55(11): 111601.

庞铭, 张啸寒, 刘光, 谭雯丹, 付威, 江国业. 预热温度对激光熔凝RuT300温度场的影响规律[J]. 激光与光电子学进展, 2019, 56(7): 071601. Ming Pang, Xiaohan Zhang, Guang Liu, Wendan Tan, Wei Fu, Guoye Jiang. Effect of Preheating Temperature on Temperature Field of Laser Melting RuT300[J]. Laser & Optoelectronics Progress, 2019, 56(7): 071601.