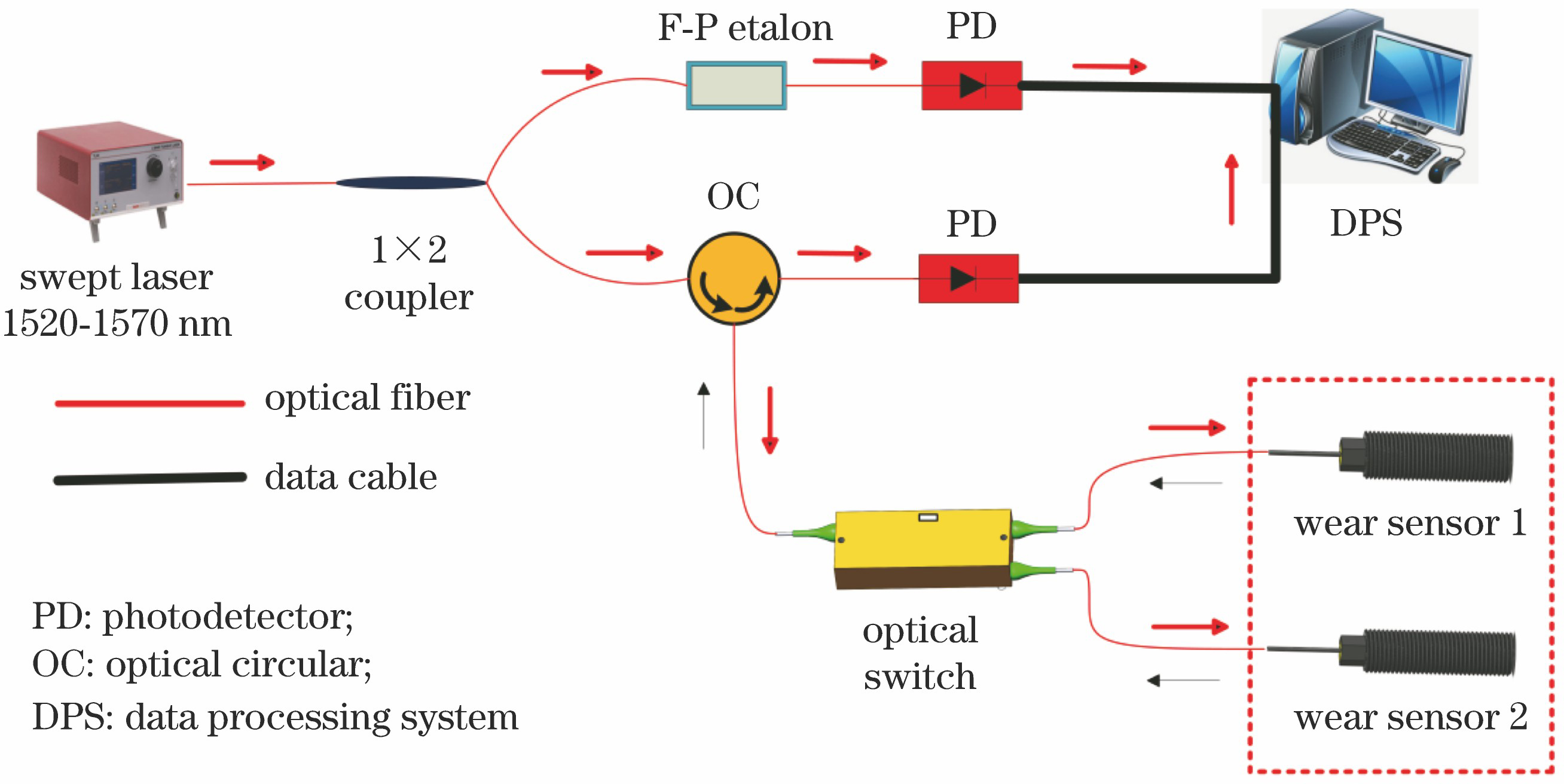

基于光纤布拉格光栅阵列的刀头磨损实时在线检测  下载: 1048次

下载: 1048次

蒋磊, 张学智, 王进, 樊晓军, 李雨晴, 褚悦, 徐棒田, 刘铁根. 基于光纤布拉格光栅阵列的刀头磨损实时在线检测[J]. 光学学报, 2019, 39(12): 1206003.

Lei Jiang, Xuezhi Zhang, Jin Wang, Xiaojun Fan, Yuqing Li, Yue Chu, Bangtian Xu, Tiegen Liu. Real-Time Online Detection of Cutter Wear Based on Fiber Bragg Grating Array[J]. Acta Optica Sinica, 2019, 39(12): 1206003.

[1] 汪晓崇, 王问斯, 吴琴. 国内刀具磨损检测系统的现状及未来发展方向展望[J]. 科技风, 2017( 26): 12.

Wang XC, Wang WS, WuQ. The present situation and prospect of future development of tool wear detection system in China[J]. Science and Technology Wind, 2017( 26): 12.

[2] . 岸田光央,[J]. 采用光纤的接触导线磨损检测系统 彭惠民, 译. 国外机车车辆工艺, 2006(2): 43-45.

KishidaM. Optical fiber contact wire wear detection system[J]. Peng H M, Transl. Foreign Locomotive & Rolling Stock Technology, 2006( 2): 43- 45.

[3] Cook N H, Subramanian K. Micro-isotope tool wear sensor[J]. Annals of the CIRP, 1978, 21(1): 67-72.

[5] 熊四昌. 基于计算机视觉的刀具磨损状态监测技术的研究[D]. 杭州: 浙江大学, 2003.

Xiong SC. Research on cutting tool wear condition monitoring based on computer vision[D]. Hangzhou: Zhejiang University, 2003.

[6] Anandakrishnan V, Mahamani A. Investigations of flank wear, cutting force, and surface roughness in the machining of Al-6061-TiB2in situ metal matrix composites produced by flux-assisted synthesis[J]. The International Journal of Advanced Manufacturing Technology, 2011, 55: 65-73.

[7] 石建, 丁宁. 基于声发射技术的砂轮磨损状况在线检测[J]. 长春大学学报, 2013, 23(8): 931-936, 950.

[8] Venkata Rao K. Murthy B S N, Mohan Rao N. Prediction of cutting tool wear, surface roughness and vibration of work piece in boring of AISI 316 steel with artificial neural network[J]. Measurement, 2014, 51: 63-70.

[9] 程格. 高速铣削模具钢Cr12MoV的切削温度及刀具磨损研究[D]. 兰州: 兰州理工大学, 2016.

ChengG. Research on cutting temperature and tool wear of Cr12MoV die steel in high-speed milling[D]. Lanzhou: Lanzhou University of Technology, 2016.

[10] 李康, 黄民, 吴国新, 等. 基于变频器输入电流的刀具磨损状态监测系统设计与实现[J]. 组合机床与自动化加工技术, 2017( 6): 90- 92, 96.

LiK, HuangM, Wu GX, et al. Design and implementation of tool wear condition monitoring system based on inverter input current[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2017( 6): 90- 92, 96.

[11] 杨丰, 李云. 基于Fitnet的刀具磨损量预测方法研究[J]. 机床与液压, 2018, 46(14): 50-51, 49.

[12] 肖忠跃, 张为民, 刘朝晖. 基于最大熵与交叉熵理论的刀具磨损检测技术[J]. 机床与液压, 2018, 46(22): 89-93.

[13] 尚伟, 王百泉. 盾构刀具磨损超声波检测技术研究[J]. 建筑机械化, 2018, 39(1): 56-59.

[14] Cao W Q, Fu P, Li X H. The diagnosis of tool wear based on EMD and GA-B-spline network[J]. Sensors & Transducers, 2013, 156(9): 195-202.

[16] 郭永兴, 熊丽, 孔建益, 等. 滑动式光纤布拉格光栅位移传感器[J]. 光学精密工程, 2017, 25(1): 50-58.

[17] 谭展, 廖常锐, 刘申, 等. 基于空芯光纤和光纤布拉格光栅的温度应变同时测量传感器[J]. 光学学报, 2018, 38(12): 1206007.

[18] 朱雨霜, 桂林, 朱玉绚. 基于最大射频强度判别法的温度传感波长解调研究[J]. 光学学报, 2019, 39(7): 0728003.

[19] 顾铮先, 凌强. 基于近PMTP区域双峰谐振效应的长周期光纤光栅应变传感理论分析[J]. 光学学报, 2016, 36(1): 0106005.

[21] 孙新民, 孙红月, 严细水. FBG传感器在量测围岩内部位移中的应用[J]. 岩石力学与工程学报, 2008, 27(S2): 3847-3851.

[22] 刘波, 牛文成, 杨亦飞, 等. 新型光纤光栅加速度传感器的设计与实现[J]. 仪器仪表学报, 2006, 27(1): 42-44.

[23] KashyapR. Fiber Bragg gratings[M]. 2nd ed. Burlington, MA: Academic Press, 2010: 130- 142.

[24] 欧进萍, 周智, 武湛君, 等. 黑龙江呼兰河大桥的光纤光栅智能监测技术[J]. 土木工程学报, 2004, 37(1): 45-49, 64.

[25] 李川. 光纤光栅:原理、技术与传感应用[M]. 北京: 科学出版社, 2005: 87- 88.

LiC. Fiber grating: principle, technology and sensing applications[M]. Beijing: Science Press, 2005: 87- 88.

蒋磊, 张学智, 王进, 樊晓军, 李雨晴, 褚悦, 徐棒田, 刘铁根. 基于光纤布拉格光栅阵列的刀头磨损实时在线检测[J]. 光学学报, 2019, 39(12): 1206003. Lei Jiang, Xuezhi Zhang, Jin Wang, Xiaojun Fan, Yuqing Li, Yue Chu, Bangtian Xu, Tiegen Liu. Real-Time Online Detection of Cutter Wear Based on Fiber Bragg Grating Array[J]. Acta Optica Sinica, 2019, 39(12): 1206003.