激光直接沉积TA2/TA15梯度材料弯曲性能的有限元模拟  下载: 1037次

下载: 1037次

胡悦, 刘莎莎, 程序, 刘栋. 激光直接沉积TA2/TA15梯度材料弯曲性能的有限元模拟[J]. 中国激光, 2020, 47(12): 1202006.

Hu Yue, Liu Shasha, Cheng Xu, Liu Dong. Finite Element Simulation on Bending Properties of TA2/TA15 Gradient Material by Laser Direct Deposition[J]. Chinese Journal of Lasers, 2020, 47(12): 1202006.

[1] Wang R J, Cheng H M, Li J Y. Stress strain analysis of notched specimen based on material property gradient[J]. Procedia Engineering, 2012, 31: 360-365.

[3] Khor K A, Dong Z L, Gu Y W. Plasma sprayed functionally graded thermal barrier coatings[J]. Materials Letters, 1999, 38(6): 437-444.

[4] Kawase M, Tago T, Kurosawa M, et al. Chemical vapor infiltration and deposition to produce a silicon carbide-carbon functionally gradient material[J]. Chemical Engineering Science, 1999, 54(15/16): 3327-3334.

[5] Canakci A, Varol T. Microstructure and properties of AA7075/Al-SiC composites fabricated using powder metallurgy and hot pressing[J]. Powder Technology, 2014, 268: 72-79.

[6] Pasha B A M, Mohamed K. Taguchi approach to influence of processing parameters on erosive wear behaviour of Al7034-T6 composites[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(10): 2163-2171.

[7] Ghorbantabar Omran J, Shafiee Afarani M, Sharifitabar M. Fast synthesis of MgAl2O4-W and MgAl2O4-W-W2B composite powders by self-propagating high-temperature synthesis reactions[J]. Ceramics International, 2018, 44(6): 6508-6513.

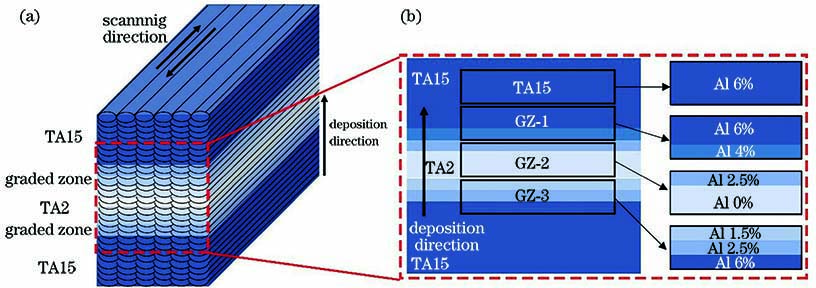

[8] Qian T T, Liu D, Tian X J, et al. Microstructure of TA2/TA15 graded structural material by laser additive manufacturing process[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(9): 2729-2736.

[10] 顾冬冬, 张红梅, 陈洪宇, 等. 航空航天高性能金属材料构件激光增材制造[J]. 中国激光, 2020, 47(5): 0500002.

[11] 姚燕生, 汪俊, 陈庆波, 等. 激光增材制造产品缺陷及其处理技术研究现状[J]. 激光与光电子学进展, 2019, 56(10): 100004.

[12] 严振宇, 李祚, 周庆军, 等. 激光立体成形TA15-Ti2AlNb双合金组织演化[J]. 应用激光, 2019, 39(5): 785-791.

[13] Lin X, Yue T M, Yang H O, et al. Solidification behavior and the evolution of phase in laser rapid forming of graded Ti6Al4V-Rene88DT alloy[J]. Metallurgical and Materials Transactions A, 2007, 38(1): 127-137.

[15] Hu Y B, Cong W L. A review on laser deposition-additive manufacturing of ceramics and ceramic reinforced metal matrix composites[J]. Ceramics International, 2018, 44(17): 20599-20612.

[16] 钦兰云, 徐丽丽, 杨光, 等. 退火方式对激光沉积TA15钛合金组织及力学性能的影响[J]. 中国激光, 2018, 45(3): 0302004.

[17] Liang Y J, Liu D, Wang H M. Microstructure and mechanical behavior of commercial purity Ti/Ti-6Al-2Zr-1Mo-1V structurally graded material fabricated by laser additive manufacturing[J]. Scripta Materialia, 2014, 74: 80-83.

[19] Zhan Z X. Experiments and numerical simulations for the fatigue behavior of a novel TA2-TA15 titanium alloy fabricated by laser melting deposition[J]. International Journal of Fatigue, 2019, 121: 20-29.

[21] Seifoori S, Mirzaei M, Afjoland H. Experimental and FE analysis for accurate measurement of deflection in CFRP and GFRP laminates under bending[J]. Measurement, 2020, 153: 107445.

[22] Li F F, Fang G. Modeling of 3D plastic anisotropy and asymmetry of extruded magnesium alloy and its applications in three-point bending[J]. International Journal of Plasticity, 2020, 130: 102704.

[24] 辛社伟. 钛合金固态相变的归纳与讨论(Ⅴ): 相与相变谈[J]. 钛工业进展, 2013, 30(3): 12-15.

Xin S W. Inductions and discussions of solid state phase transformation of titanium alloy(Ⅴ)-talking about phase and phase-transformation[J]. Titanium Industry Progress, 2013, 30(3): 12-15.

[26] Sarrazin-Baudoux C. Abnormal near-threshold fatigue crack propagation of Ti alloys: role of the microstructure[J]. International Journal of Fatigue, 2005, 27(7): 773-782.

[27] Wang Y F, Chen R, Cheng X, et al. Effects of microstructure on fatigue crack propagation behavior in a bi-modal TC11 titanium alloy fabricated via laser additive manufacturing[J]. Journal of Materials Science & Technology, 2019, 35(2): 403-408.

[28] 杨光, 刘佳蓬, 钦兰云, 等. 激光沉积TA15钛合金显微组织及高周疲劳性能研究[J]. 红外与激光工程, 2018, 47(11): 1106003.

胡悦, 刘莎莎, 程序, 刘栋. 激光直接沉积TA2/TA15梯度材料弯曲性能的有限元模拟[J]. 中国激光, 2020, 47(12): 1202006. Hu Yue, Liu Shasha, Cheng Xu, Liu Dong. Finite Element Simulation on Bending Properties of TA2/TA15 Gradient Material by Laser Direct Deposition[J]. Chinese Journal of Lasers, 2020, 47(12): 1202006.