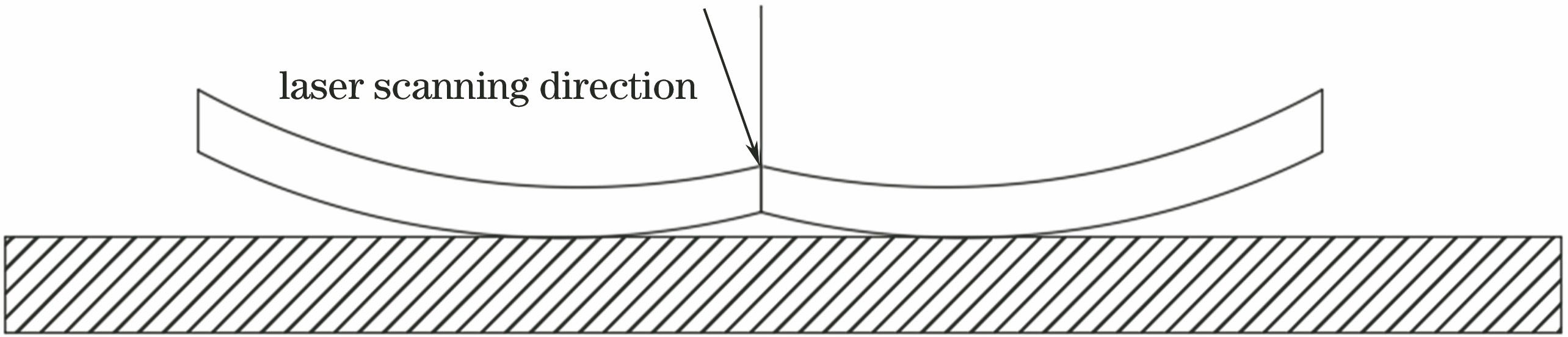

激光深熔焊接X65油气管线钢焊缝的成形机理及性能分析  下载: 988次

下载: 988次

江国业, 刘宇平, 雷璞, 庞铭, 李敏, 付威. 激光深熔焊接X65油气管线钢焊缝的成形机理及性能分析[J]. 激光与光电子学进展, 2020, 57(3): 031406.

Guoye Jiang, Yuping Liu, Pu Lei, Ming Pang, Min Li, Wei Fu. Forming Mechanism and Performance Analysis of X65 Oil and Gas Steel Pipeline Weld Fabricated by Laser Deep-Penetration Welding[J]. Laser & Optoelectronics Progress, 2020, 57(3): 031406.

[1] 邓彩艳, 张玉凤, 霍立兴, 等. 24(3): 13-16, Ⅲ-Ⅳ[J]. . X65管线钢焊接接头CTOD断裂韧度. 焊接学报, 2003.

Deng CY, Zhang YF, Huo LX, et al., 2003, 24(3): 13-16, Ⅲ-Ⅳ.

[2] 徐震. X65管线钢的本构关系及失效判据研究[J]. 石油工程建设, 2014, 40(3): 23-27.

Xu Z. Study on constitutive relation and failure criteria of X65 pipeline steel[J]. Petroleum Engineering Construction, 2014, 40(3): 23-27.

[3] 郭鹏飞, 王晓南, 朱国辉, 等. X100管线钢光纤激光焊接头的显微组织及性能[J]. 中国激光, 2017, 44(12): 1202003.

[4] You Y, Shang C J, Nie W J, et al. Investigation on the microstructure and toughness of coarse grained heat affected zone in X-100 multi-phase pipeline steel with high Nb content[J]. Materials Science and Engineering: A, 2012, 558: 692-701.

[5] 曹永利, 黄福祥, 王勤. 我国长输管道焊接技术进展及发展方向[J]. 石油科技论坛, 2012, 31(1): 7-11, 68.

Cao Y L, Huang F X, Wang Q. Research progress and development direction of long distance pipeline welding technology in China[J]. Oil Forum, 2012, 31(1): 7-11, 68.

[6] 郭瑞杰, 付桂英, 杨天冰, 等. 长输油气管道激光焊接技术[J]. 焊管, 2007, 30(6): 78-80, 97.

Guo R J, Fu G Y, Yang T B, et al. Laser welding technology of long distance pipeline[J]. Welded Pipe and Tube, 2007, 30(6): 78-80, 97.

[7] 彭进, 王星星, 李刚, 等. 激光填丝焊对熔池动态行为及焊缝成形的影响[J]. 中国激光, 2017, 44(11): 1102004.

[8] 黄怡洁, 高向东, 林少铎. 激光焊接参数对有机玻璃与不锈钢接头力学性能的影响[J]. 中国激光, 2017, 44(12): 1202006.

[9] 彭进, 胡素梦, 王星星, 等. 填材对激光焊接匙孔与熔池三维瞬态行为的影响[J]. 中国激光, 2018, 45(1): 0102003.

[10] 黄根哲, 刘双宇, 刘凤德, 等. 高强钢非对称双面双弧焊微观组织演变和显微硬度分布规律的研究[C]∥第二十次全国焊接学术会议论文集.[出版地不详: 出版者不详], 2015.

Huang GZ, Liu SY, Liu FD, et al. Study on microstructure evolution and microhardness distribution of asymmetric double-sided double arc welding of high strength steel[ C]∥Proceedings of the 20th National Welding Conference.[S.l.: s.n.], 2015.

[11] 李敬勇, 邱硕, 仇晨龙. 惯性摩擦焊接头非对称性分析[J]. 焊接学报, 2014, 35(12): 81-84.

Li J Y, Qiu S, Qiu C L. Asymmetry of inertia friction welding joint[J]. Transactions of the China Welding Institution, 2014, 35(12): 81-84.

[12] 汪杰, 郭鹏飞, 王晓南, 等. X100管线钢激光焊接接头显微组织及耐腐蚀性能研究[J]. 应用激光, 2017, 37(6): 835-841.

[13] Zhao Y, Zhang S, Hu W. Effect of welding speed on microstructure, hardness and tensile properties in laser welding of advanced high strength steel[J]. Science and Technology of Welding and Joining, 2013, 18(7): 581-590.

[14] 杨智华, 杨尚磊, 庹文海, 等. 焊接速度对TRIP590高强钢激光焊接接头组织与力学性能的影响[J]. 机械工程材料, 2017, 41(4): 94-97.

Yang Z H, Yang S L, Tuo W H, et al. Effects of welding speed on microstructure and mechanical properties of laser welded joint of TRIP590 high strength steel[J]. Materials for Mechanical Engineering, 2017, 41(4): 94-97.

[15] 蒋贤海, 谌小平. 焊接速度对高强镀锌钢板激光焊接头组织和性能的影响[J]. 热加工工艺, 2015, 44(15): 185-187.

Jiang X H, Chen X P. Effect of welding speed on microstructure and properties of laser welded joints of high strength galvanized steel[J]. Hot Working Technology, 2015, 44(15): 185-187.

[16] 程东海, 黄继华, 林海凡, 等. TC4钛合金激光拼焊接头显微组织及力学性能分析[J]. 焊接学报, 2009, 30(2): 103-106.

Cheng D H, Huang J H, Lin H F, et al. Microstructure and mechanical analysis of Ti-6Al-4V laser butt weld joint[J]. Transactions of the China Welding Institution, 2009, 30(2): 103-106.

[17] 端强, 阎军, 朱国辉, 等. X80管线钢焊缝组织及裂纹形成机制[J]. 金属热处理, 2015, 40(11): 68-72.

Duan Q, Yan J, Zhu G H, et al. Microstructure and crack formation mechanism of X80 pipeline steel welded seam[J]. Heat Treatment of Metals, 2015, 40(11): 68-72.

[18] 景财年, 倪晓梅, 李怀学, 等. 焊接速度对TRIP590钢激光焊接头组织性能的影响[J]. 材料热处理学报, 2014, 35(6): 111-114.

Jing C N, Ni X M, Li H X, et al. Effect of welding speed on microstructure and property of laser welding joint for TRIP590 steel[J]. Transactions of Materials and Heat Treatment, 2014, 35(6): 111-114.

[19] 谷诤巍, 于思彬, 韩立军, 等. 激光焊接速度对超高强度钢焊缝微观组织和显微硬度的影响[J]. 吉林大学学报(工学版), 2012, 42(3): 656-659.

Gu Z W, Yu S B, Han L J, et al. Effect of welding speed on microstructure and micro hardness of the weld seam of laser welded ultra-high strength steel[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(3): 656-659.

[22] 环鹏程, 王晓南, 朱天才, 等. 800 MPa级热轧高强钢激光焊接接头的组织和力学性能[J]. 中国激光, 2019, 46(1): 0102002.

江国业, 刘宇平, 雷璞, 庞铭, 李敏, 付威. 激光深熔焊接X65油气管线钢焊缝的成形机理及性能分析[J]. 激光与光电子学进展, 2020, 57(3): 031406. Guoye Jiang, Yuping Liu, Pu Lei, Ming Pang, Min Li, Wei Fu. Forming Mechanism and Performance Analysis of X65 Oil and Gas Steel Pipeline Weld Fabricated by Laser Deep-Penetration Welding[J]. Laser & Optoelectronics Progress, 2020, 57(3): 031406.