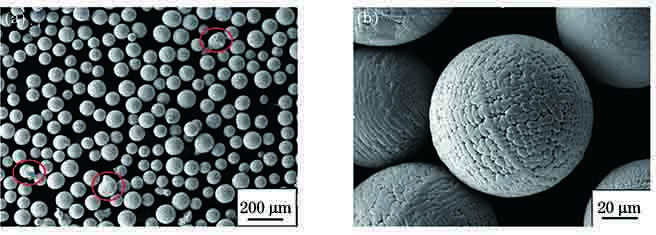

选区激光熔化对GCr15高碳钢成形性能的研究  下载: 750次

下载: 750次

刘世锋, 李云哲, 张智昶, 张光曦, 杨鑫, 王岩. 选区激光熔化对GCr15高碳钢成形性能的研究[J]. 激光与光电子学进展, 2020, 57(21): 211402.

Liu Shifeng, Li Yunzhe, Zhang Zhichang, Zhang Guangxi, Yang Xin, Wang Yan. Study on Effect of Selective Laser Melting on Formability of GCr15 High Carbon Steel[J]. Laser & Optoelectronics Progress, 2020, 57(21): 211402.

[1] 刘雅政, 周乐育, 张朝磊, 等. 重大装备用高品质轴承用钢的发展及其质量控制[J]. 钢铁, 2013, 48(8): 1-8.

Liu Y Z, Zhou L Y, Zhang C L, et al. Development and quality control of bearing steel for heavy equipment[J]. Iron & Steel, 2013, 48(8): 1-8.

[2] 杨永强, 王迪, 吴伟辉. 金属零件选区激光熔化直接成型技术研究进展[J]. 中国激光, 2011, 38(6): 0601007.

[3] 杨永强, 陈杰, 宋长辉, 等. 金属零件激光选区熔化技术的现状及进展[J]. 激光与光电子学进展, 2018, 55(1): 011401.

[5] Cacace S, Demir A G, Semeraro Q. Densification mechanism for different types of stainless steel powders in selective laser melting[J]. Procedia CIRP, 2017, 62: 475-480.

[6] Krell J, Röttger A, Geenen K, et al. General investigations on processing tool steel X40CrMoV5-1 with selective laser melting[J]. Journal of Materials Processing Technology, 2018, 255: 679-688.

[8] 宗学文, 高倩, 周宏志, 等. 体激光能量密度对选区激光熔化316L不锈钢各向异性的影响[J]. 中国激光, 2019, 46(5): 0502003.

[9] 陈洪宇, 顾冬冬, 顾荣海, 等. 5CrNi4Mo模具钢选区激光熔化增材制造组织演变及力学性能研究[J]. 中国激光, 2016, 43(2): 0203003.

[10] Krell J, Röttger A, Geenen K, et al. General investigations on processing tool steel X40CrMoV5-1 with selective laser melting[J]. Journal of Materials Processing Technology, 2018, 255: 679-688.

[14] TakamichiI, Roderick I L G. The physical properties of liquid metals[M]. 1st ed. Oxford: Clarendon Press, 1993.

[16] Li Y L, Gu D D. Parametric analysis of thermal behavior during selective laser melting additive manufacturing of aluminum alloy powder[J]. Materials & Design, 2014, 63: 856-867.

[17] 陈帅, 陶凤和, 贾长治. 选区激光熔化成形4Cr5MoSiV1钢回火处理后显微组织和力学性能[J]. 中国激光, 2019, 46(10): 1002005.

刘世锋, 李云哲, 张智昶, 张光曦, 杨鑫, 王岩. 选区激光熔化对GCr15高碳钢成形性能的研究[J]. 激光与光电子学进展, 2020, 57(21): 211402. Liu Shifeng, Li Yunzhe, Zhang Zhichang, Zhang Guangxi, Yang Xin, Wang Yan. Study on Effect of Selective Laser Melting on Formability of GCr15 High Carbon Steel[J]. Laser & Optoelectronics Progress, 2020, 57(21): 211402.