典型激光参数对高硅铝合金缸套表面微坑几何形貌影响  下载: 950次

下载: 950次

吕佳霏, 韩晓光, 赫冬, 杜凤鸣, 陈玉珍, 徐久军. 典型激光参数对高硅铝合金缸套表面微坑几何形貌影响[J]. 激光与光电子学进展, 2020, 57(13): 131402.

Jiafei Lü, Xiaoguang Han, Dong He, Fengming Du, Yuzhen Chen, Jiujun Xu. Effect of Typical Laser Parameters on Micro-Dimple Geometry of High-Silicon Aluminum Alloy Cylinder Liner Surface[J]. Laser & Optoelectronics Progress, 2020, 57(13): 131402.

[1] Hamilton D B, Walowit J A, Allen C M. A theory of lubrication by micro irregularities[J]. Journal of Basic Engineering, 1966, 88(1): 177-185.

[2] Shi C C, Yu A B, Wu J Z, et al. Comparisons of tribological properties between laser and drilled dimple textured surfaces of medium carbon steel[J]. Industrial Lubrication and Tribology, 2017, 69(4): 516-526.

[3] Greco A, Martini A, Liu Y C, et al. Rolling contact fatigue performance of vibro-mechanical textured surfaces[J]. Tribology Transactions, 2010, 53(4): 610-620.

[4] Parreira J G, Gallo C A, Costa H L. New advances on mask less electrochemical texturing (MECT) for tribological purposes[J]. Surface and Coatings Technology, 2012, 212: 1-13.

[5] Vilhena L M. Sedla ek M, Podgornik B, et al. Surface texturing by pulsed Nd∶YAG laser[J]. Tribology International, 2009, 42(10): 1496-1504.

[6] Ahmmed K, Grambow C, Kietzig A M. Fabrication of micro/nano structures on metals by femtosecond laser micromachining[J]. Micromachines, 2014, 5(4): 1219-1253.

[7] Vincent C, Monteil G, Barriere T, et al. Control of the quality of laser surface texturing[J]. Microsystem Technologies, 2008, 14(9/10/11): 1553-1557.

[8] Park S J, Norton D P. Ion beam assisted texturing of polycrystalline Y2O3 films deposited via electron-beam evaporation[J]. Thin Solid Films, 2006, 510(1/2): 143-147.

[9] 郑晓辉, 宋皓, 张庆, 等. 激光表面织构化对材料摩擦学性能影响的研究进展[J]. 材料导报, 2017, 31(17): 68-74.

Zheng X H, Song H, Zhang Q, et al. Effect of laser surface texturing on tribological properties of materials: a review[J]. Materials Review, 2017, 31(17): 68-74.

[10] Segu D Z, Kim J H, Choi S G, et al. Application of Taguchi techniques to study friction and wear properties of MoS2 coatings deposited on laser textured surface[J]. Surface and Coatings Technology, 2013, 232: 504-514.

[11] 华希俊, 葛汉青, 符永宏, 等. 内燃机气缸内孔分区异化激光微织构技术研究[J]. 内燃机工程, 2015, 36(4): 140-143.

Hua X J, Ge H Q, Fu Y H, et al. Research on discriminating partition laser surface micro-texturing technology of engine cylinder[J]. Chinese Internal Combustion Engine Engineering, 2015, 36(4): 140-143.

[12] 华希俊, 张加力, 解玄, 等. GCr15轴承钢表面的激光凹/凸微织构工艺[J]. 中国激光, 2019, 46(3): 0302009.

[13] Ahuir-Torres J I, Arenas M A, Perrie W, et al. Influence of laser parameters in surface texturing of Ti6Al4V and AA2024-T3 alloys[J]. Optics and Lasers in Engineering, 2018, 103: 100-109.

[14] 郑卜祥, 姜歌东, 王文君, 等. 超快脉冲激光对钛合金的烧蚀特性与作用机理[J]. 西安交通大学学报, 2014, 48(12): 21-28.

Zheng B X, Jiang G D, Wang W J, et al. Ablation characteristics and interaction mechanism of ultra-fast pulse laser-induced damage in titanium alloy[J]. Journal of Xi'an Jiaotong University, 2014, 48(12): 21-28.

[15] 符永宏, 刘强宪, 叶云霞, 等. 同点间隔多次激光微织构工艺研究[J]. 中国激光, 2015, 42(12): 1203005.

[16] Dwivedi D K. Adhesive wear behaviour of cast aluminium-silicon alloys: overview[J]. Materials & Design (1980-2015), 2010, 31(5): 2517-2531.

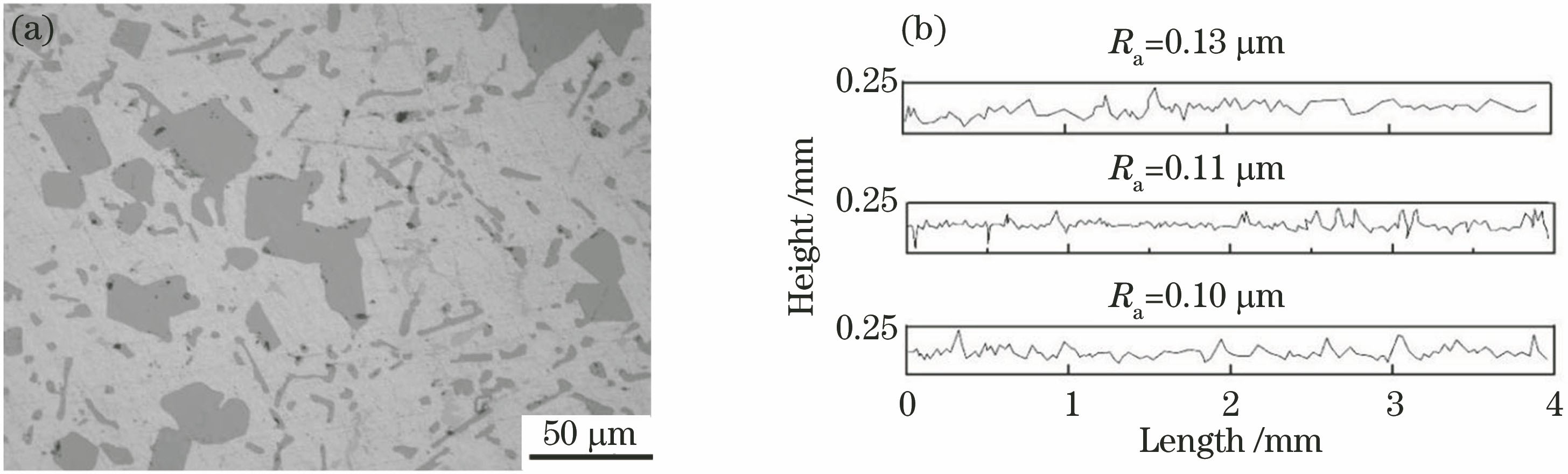

[17] 李承娣, 徐佳子, 沈岩, 等. 表面硅颗粒整形对高硅铝合金缸套摩擦磨损性能的影响[J]. 中国表面工程, 2016, 29(6): 8-14.

Li C D, Xu J Z, Shen Y, et al. Effects of shaping silicon particles on friction and wear properties of Al-Si alloy plated cylinder liner[J]. China Surface Engineering, 2016, 29(6): 8-14.

[18] 朱峰. 对置往复式摩擦磨损试验机研制及其试验[D]. 大连: 大连海事大学, 2011.

ZhuF. Development of a contraposition reciprocating test rig for tribological study and friction & wear test[D]. Dalian: Dalian Maritime University, 2011.

[19] 虞钢, 虞和济. 激光制造工艺力学[M]. 北京: 国防工业出版社, 2012: 54- 60.

YuG, Yu HJ. Laser manufacturing process mechanics[M]. Beijing: National Defense Industry Press, 2012: 54- 60.

[20] Mannion P, Magee J, Coyne E, et al. The effect of damage accumulation behaviour on ablation thresholds and damage morphology in ultrafast laser micro-machining of common metals in air[J]. Applied Surface Science, 2004, 233: 275-287.

[21] Eichstädt J. Römer G R B E, Huis in ‘t Veld A J. Determination of irradiation parameters for laser-induced periodic surface structures[J]. Applied Surface Science, 2013, 264: 79-87.

[22] 刘强宪. 脉冲激光表面烧蚀微织构工艺与激光器系统研究[D]. 镇江: 江苏大学, 2016: 35- 40.

Liu QX. Pulsed laser surface ablation micro-texture process and laser system[D]. Zhenjiang: Jiangsu University, 2016: 35- 40.

吕佳霏, 韩晓光, 赫冬, 杜凤鸣, 陈玉珍, 徐久军. 典型激光参数对高硅铝合金缸套表面微坑几何形貌影响[J]. 激光与光电子学进展, 2020, 57(13): 131402. Jiafei Lü, Xiaoguang Han, Dong He, Fengming Du, Yuzhen Chen, Jiujun Xu. Effect of Typical Laser Parameters on Micro-Dimple Geometry of High-Silicon Aluminum Alloy Cylinder Liner Surface[J]. Laser & Optoelectronics Progress, 2020, 57(13): 131402.