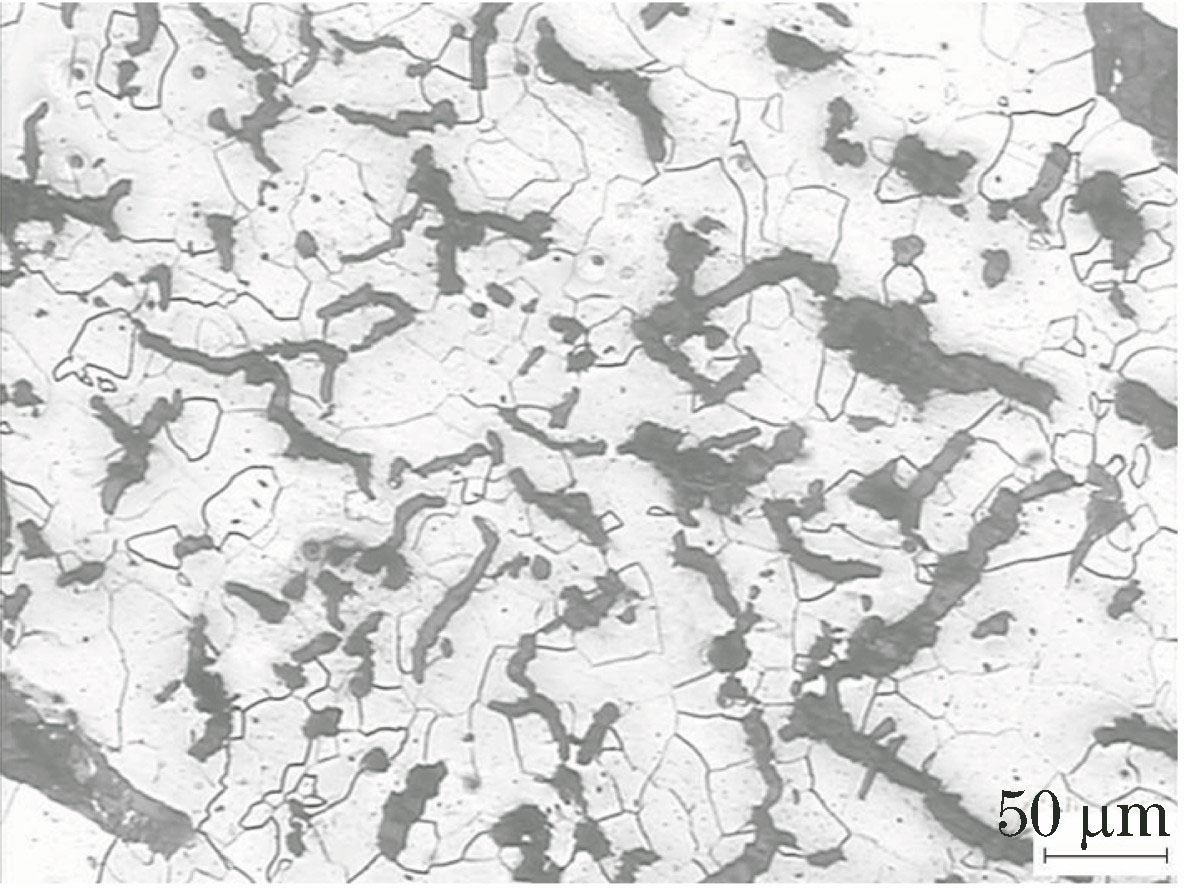

激光表面重熔蠕墨铸铁气门座微观特性分析和裂纹抑制研究  下载: 712次

下载: 712次

庞铭, 谭雯丹. 激光表面重熔蠕墨铸铁气门座微观特性分析和裂纹抑制研究[J]. 激光与光电子学进展, 2019, 56(21): 211402.

Ming Pang, Wendan Tan. Microscopic Characteristic Analysis and Crack Suppression of Laser-Surface Remelting of Vermicular-Graphite Cast-Iron Valve Seats[J]. Laser & Optoelectronics Progress, 2019, 56(21): 211402.

[1] 谭雯丹, 庞铭, 江国业, 等. 高强化柴油机气门座激光相变硬化温度场的数值模拟[J]. 激光与光电子学进展, 2018, 55(11): 111601.

[2] 庞铭, 谭雯丹, 张啸寒, 等. 基于光束变换的激光相变硬化气门座温度场数值模拟[J]. 热加工工艺, 2018, 47(22): 202-205.

[3] 闫军芳. 蠕墨铸铁组织形貌及其性能的研究[D]. 济南: 山东大学, 2014.

Yan JF. Research on microstructure and properties of compacted graphite iron[D]. Jinan: Shandong University, 2014.

[4] . 蠕墨铸铁——现代柴油发动机缸体和缸盖的材料[J]. 铸造技术, 2009, 30(4): 455-460.

[5] 黄本生, 高钰枭, 陈鹏, 等. 高频感应熔覆TiN/Co涂层组织及性能研究[J]. 材料导报, 2018, 32(13): 2272-2277.

[6] 魏德强, 刘科, 王荣. 45钢电子束扫描相变硬化组织和硬度的研究[J]. 机械工程学报, 2012, 48(2): 127-132.

[7] 陈虎城, 魏德强, 王晓冰. 45钢电子束处理表面相变硬化的横截面硬度分布[J]. 金属热处理, 2017, 42(10): 159-163.

[8] Šebek M, Falat L. Ková F, et al. The effects of laser surface hardening on microstructural characteristics and wear resistance of AISI H11 hot work tool steel[J]. Archives of Metallurgy and Materials, 2017, 62(3): 1721-1726.

[10] 吴王平, 刘剑文, 王辉, 等. 激光熔覆NiAl-SiC复合涂层的组织与摩擦性能[J]. 激光与光电子学进展, 2018, 55(9): 091406.

[11] 吴国龙, 任方成, 姚建华, 等. 半导体激光熔覆新型Co基合金耐擦伤性机制[J]. 中国激光, 2017, 44(6): 0602006.

[12] 葛茂忠, 项建云, 汤洋. 激光冲击处理对TC4修复件疲劳裂纹扩展速率的影响[J]. 激光与光电子学进展, 2018, 55(7): 071405.

[13] 庞铭, 张啸寒, 付威, 等. RuT300气门座激光熔凝温度场数值模拟[J]. 热加工工艺, 2018, 47(22): 117-123.

[14] 庞铭, 张啸寒, 刘光, 等. 预热温度对激光熔凝RuT300温度场的影响规律[J]. 激光与光电子学进展, 2019, 56(7): 071601.

[15] 程秀, 胡树兵, 宋武林, 等. 球墨铸铁的等离子束熔凝组织和耐蚀性研究[J]. 五邑大学学报(自然科学版), 2013, 27(3): 41-45.

[16] 李美艳. 高铬铸钢轧辊激光熔凝改性研究[D]. 青岛: 中国石油大学, 2010.

Li MY. Study on modification of high chrome cast steel roller by laser surface melting[D]. Qingdao: China University of Petroleum, 2010.

[17] 孟云龙, 杨胶溪, 张健全, 等. 激光熔凝对AerMet100钢显微组织及性能的影响[J]. 激光与光电子学进展, 2018, 55(2): 021414.

[18] 张庆茂, 刘文今. 激光熔凝层组织与摩擦学特性的研究[J]. 强激光与粒子束, 2006, 18(3): 389-392.

庞铭, 谭雯丹. 激光表面重熔蠕墨铸铁气门座微观特性分析和裂纹抑制研究[J]. 激光与光电子学进展, 2019, 56(21): 211402. Ming Pang, Wendan Tan. Microscopic Characteristic Analysis and Crack Suppression of Laser-Surface Remelting of Vermicular-Graphite Cast-Iron Valve Seats[J]. Laser & Optoelectronics Progress, 2019, 56(21): 211402.