基于线结构光的核燃料棒表面裂缝尺寸测量  下载: 833次

下载: 833次

咸凯强, 庞静珠, 胡俊. 基于线结构光的核燃料棒表面裂缝尺寸测量[J]. 激光与光电子学进展, 2020, 57(22): 221013.

Kaiqiang Xian, Jingzhu Pang, Jun Hu. Surface Crack Size Detection in Nuclear Fuel Rods Based on Line Structured Light[J]. Laser & Optoelectronics Progress, 2020, 57(22): 221013.

[1] 汤勃, 孔建益, 伍世虔. 机器视觉表面缺陷检测综述[J]. 中国图象图形学报, 2017, 22(12): 1640-1663.

[2] 胡晨旭. 核电厂一回路管座焊缝超声波检测仿真研究[J]. 核动力工程, 2020, 41(2): 145-149.

[3] 孙永生, 李猛, 刘恒, 等. 基于声发射检测技术的滚动轴承缺陷检测[J]. 无损检测, 2015, 37(8): 17-20, 60.

Sun Y S, Li M, Liu H, et al. Bearing fault detection based on acoustic emission technique[J]. Nondestructive Testing Technologying, 2015, 37(8): 17-20, 60.

[4] 文玉忠. 基于分布式光纤传感检测法的水利施工混凝土裂缝检测效果分析[J]. 水利技术监督, 2019, 27(2): 18-20, 154.

[5] 卢荣胜, 吴昂, 张腾达, 视觉, 等. 检测技术及其在缺陷检测中的应用综述[J]. 光学学报, 2018, 38(8): 0815002.

[6] 刘丹, 张斌, 李慧娴, 等. 复杂背景下微小圆柱端面缺陷检测方法研究[J]. 激光与光电子学进展, 2018, 55(6): 061006.

[7] 高军强, 刘桂华. 多摄像机线结构光的钢轨表面三维缺陷检测[J]. 机械设计与制造, 2017( 3): 170- 172, 176.

Gao JQ, Liu GH. 3D defect detection technology for rail surface with multi-camera line structure light[J]. Machinery Design & Manufacture, 2017( 3): 170- 172, 176.

[8] Tsai D M, Hsieh C Y. Automated surface inspection for directional textures[J]. Image and Vision Computing, 1999, 18(1): 49-62.

[9] 李书华, 周亚同, 王丹, 等. 基于机器视觉的聚氯乙烯管材表面缺陷检测[J]. 激光与光电子学进展, 2019, 56(13): 131006.

[10] Alippi C, Casagrande E, Scotti F, et al. Composite real-time image processing for railways track profile measurement[J]. IEEE Transactions on Instrumentation and Measurement, 2000, 49(3): 559-564.

[11] 王颖, 韩静文, 金翠云, 等. 圆结构光视觉三维点管道缺陷检测及重构[J]. 应用光学, 2014, 35(3): 441-445.

[12] 刘婷婷, 王培光, 张娜. 基于Zernike矩亚像素的高反光金属工件缺陷检测[J]. 激光与光电子学进展, 2019, 56(12): 121203.

[13] 王耀东, 余祖俊, 白彪, 等. 基于图像处理的地铁隧道裂缝识别算法研究[J]. 仪器仪表学报, 2014, 35(7): 1489-1496.

Wang Y D, Yu Z J, Bai B, et al. Research on image processing based subway tunnel crack identification algorithm[J]. Chinese Journal of Scientific Instrument, 2014, 35(7): 1489-1496.

[14] 苏俊宏, 刘胜利. 圆柱型高精密零件表面缺陷检测及形貌分析[J]. 激光与光电子学进展, 2014, 51(4): 041202.

[15] 李克斌, 余厚云, 周申江. 基于形态学特征的机械零件表面划痕检测[J]. 光学学报, 2018, 38(8): 0815027.

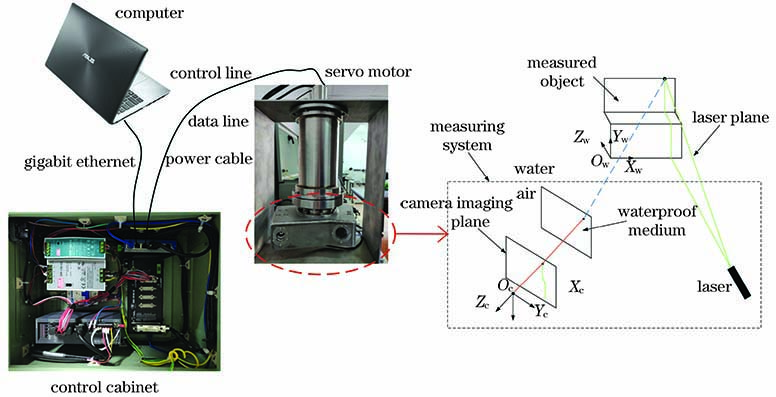

[16] 刘志伟. 基于线结构光的核燃料组件缺陷水下检测装置研究[D]. 上海: 东华大学, 2019: 17- 21.

Liu ZW. Research on underwater detection device for nuclear fuel assembly defects based on line structured light[D]. Shanghai: Donghua University, 2019: 17- 21.

[17] . A threshold selection method from gray-level histograms[J]. IEEE Transactions on Systems, Man, and Cybernetics, 1979, 9(1): 62-66.

咸凯强, 庞静珠, 胡俊. 基于线结构光的核燃料棒表面裂缝尺寸测量[J]. 激光与光电子学进展, 2020, 57(22): 221013. Kaiqiang Xian, Jingzhu Pang, Jun Hu. Surface Crack Size Detection in Nuclear Fuel Rods Based on Line Structured Light[J]. Laser & Optoelectronics Progress, 2020, 57(22): 221013.