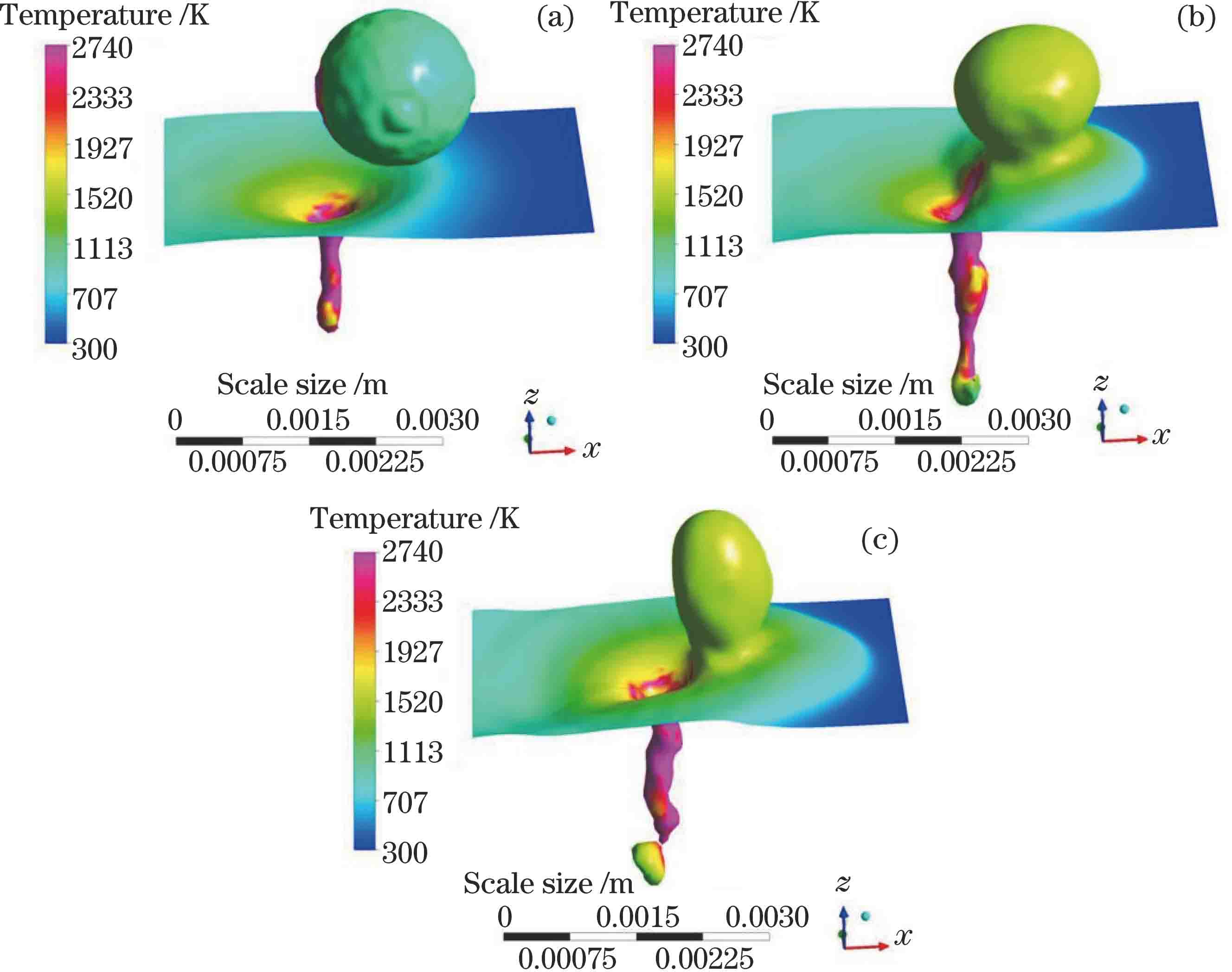

熔滴对激光焊接匙孔与熔池影响的数值模拟  下载: 911次

下载: 911次

彭进, 许红巧, 王星星, 殷利迎, 李宁宁, 李俐群. 熔滴对激光焊接匙孔与熔池影响的数值模拟[J]. 中国激光, 2020, 47(7): 0702004.

Peng Jin, Xu Hongqiao, Wang Xingxing, Yin liying, Li Ningning, Li Liqun. Numerical Simulation of Influence of Droplet on Keyhole and Molten Pool of Laser Welding[J]. Chinese Journal of Lasers, 2020, 47(7): 0702004.

[1] 吴向阳, 徐剑侠, 高学松, 等. 激光-MIG复合焊接热过程与熔池流场的数值分析[J]. 中国激光, 2019, 46(9): 0902003.

[2] 刘佳, 李忠, 石岩, 等. 光丝距对激光-电弧复合焊接熔池表面流动的影响[J]. 中国激光, 2018, 45(10): 1002004.

[3] Fabbro R, Chouf K. Keyhole modeling during laser welding[J]. Journal of Applied Physics, 2000, 87(9): 4075-4083.

[4] Ki H, Mazumder J, Mohanty P S. Modeling of laser keyhole welding: part I. Mathematical modeling, numerical methodology, role of recoil pressure, multiple reflections, and free surface evolution[J]. Metallurgical and Materials Transactions A, 2002, 33(6): 1817-1830.

[5] Ki H, Mazumder J, Mohanty P S. Modeling of laser keyhole welding: part II. Simulation of keyhole evolution, velocity, temperature profile, and experimental verification[J]. Metallurgical and Materials Transactions A, 2002, 33(6): 1831-1842.

[7] Zhao H Y, Niu W C, Zhang B, et al. Modelling of keyhole dynamics and porosity formation considering the adaptive keyhole shape and three-phase coupling during deep-penetration laser welding[J]. Journal of Physics D, 2011, 44(48): 485302.

[8] 史平安, 万强, 颜怡霞, 等. 焊接熔池流体动力学行为的数值模拟和实验研究[J]. 材料热处理学报, 2017, 38(8): 134-144.

Shi P A, Wan Q, Yan Y X, et al. Simulation and experimental study on fluid dynamics behavior of welding pool and keyhole in laser welding process[J]. Transactions of Materials and Heat Treatment, 2017, 38(8): 134-144.

[9] Lu F G, Li X B, Li Z G, et al. Formation and influence mechanism of keyhole-induced porosity in deep-penetration laser welding based on 3D transient modeling[J]. International Journal of Heat and Mass Transfer, 2015, 90: 1143-1152.

[10] Cho J H, Na S J. Three-dimensional analysis of molten pool in GMA-laser hybrid welding[J]. Welding Journal (Miami, Fla), 2009, 88(2): 35S-43S.

[11] 庞盛永. 激光深熔焊接瞬态小孔和运动熔池行为及相关机理研究[D]. 武汉: 华中科技大学, 2011: 94- 115.

Pang SY. A study on the transient keyhole and moving weld pool behaviors and mechanisms of deep penetration laser welding[D]. Wuhan: Huazhong University of Science and Technology, 2011: 94- 115.

[12] 彭进, 胡素梦, 王星星, 等. 填材对激光焊接匙孔与熔池三维瞬态行为的影响[J]. 中国激光, 2018, 45(1): 0102003.

彭进, 许红巧, 王星星, 殷利迎, 李宁宁, 李俐群. 熔滴对激光焊接匙孔与熔池影响的数值模拟[J]. 中国激光, 2020, 47(7): 0702004. Peng Jin, Xu Hongqiao, Wang Xingxing, Yin liying, Li Ningning, Li Liqun. Numerical Simulation of Influence of Droplet on Keyhole and Molten Pool of Laser Welding[J]. Chinese Journal of Lasers, 2020, 47(7): 0702004.