[1] Frank R, Luciano M, Pentti K, et al. Advanced joining techniques in European shipbuilding[J]. Journal of Ship Production, 2004, 20(3): 200-210.

[2] Katsuhiro M. High power laser applications in nippon steel corporation[J]. Proceedings of SPIE, 2000, 3888: 533-542.

[3] Staufer H. Laser hybrid welding for industrial applications[J]. Proceedings of SPIE, 2007, 6346: 634614.

[4] Reisgen U, Olschok S, Jakobs S, et al. Laser beam welding under vacuum of high grade materials[J]. Welding in the World, 2016, 60(3): 403-413.

[5] BörnerC,

DilgerK,

RomingerV.

Influence of ambient pressure on spattering and weld seam quality in laser beam welding with the solid-state laser[C]. Proceedings of the 30th ICALEO,

2011:

23-

27.

[6] Jiang M, Tao W, Wang S, et al. Effect of ambient pressure on interaction between laser radiation and plasma plume in fiber laser welding[J]. Vacuum, 2017, 138: 70-79.

[7] Luo Y, Tang X H, Lu F G, et al. Effect of subatmospheric pressure on plasma plume in fiber laser welding[J]. Journal of Materials Processing Technology, 2015, 215: 219-224.

[8] Youhei A, Yousuke K, Hiroshi N, et al. Effect of reduced pressure atmosphere on weld geometry in partial penetration laser welding of stainless steel and aluminium alloy with high power and high brightness laser[J]. Science and Technology of Welding and Joining, 2014, 19(4): 324-332.

[9] . Reisgen U. Laser beam welding under reduced pressure—range of possible applications for thick-plates[J]. Stahlbau, 2015, 84: 635-642.

[10] Sokolov M, Salminen A, Katayama S, et al. Reduced pressure laser welding of thick section structural steel[J]. Journal of Materials Processing Technology, 2015, 219: 278-285.

[11] Reisgen U, Olschok S, Turner C. Welding of thick plate copper with laser beam welding under vacuum[J]. Journal of Laser Applications, 2017, 29(2): 022402.

[12] Katayama S, Kobayashi Y, Mizutani M, et al. Effect of vacuum on penetration and defects in laser welding[J]. Journal of Laser Applications, 2001, 13(5): 187-192.

[13] Kawahito Y, Kinoshita K, Matsumoto N, et al. Effect of weakly ionised plasma on penetration of stainless steel weld produced with ultra high power density fibre laser[J]. Science and Technology of Welding and Joining, 2008, 13(8): 749-753.

[14] Cai C, Peng G C, Li L Q, et al. Comparative study on laser welding characteristics of aluminium alloy under atmospheric and subatmospheric pressures[J]. Science and Technology of Welding and Joining, 2014, 19(7): 547-553.

[15] 彭根琛.

铝与镍合金的真空环境激光焊接特性研究[D].

哈尔滨: 哈尔滨工业大学,

2015.

Peng GC.

Laser welding characteristics of aluminum and nickel-base alloys under vacuum environment[D].

Harbin: Harbin Institute of Technology,

2015.

[16] 罗燕.

负压激光焊接过程蒸气羽烟及熔池行为研究[D].

上海: 上海交通大学,

2015.

LuoY.

Research on plasma plume and molten pool behavior in fiber laser welding under subatmospheric pressure[D].

Shanghai: Shanghai Jiao Tong University,

2015:

32-

33.

[17] Wu Q, Gong J K, Chen G Y, et al. Research on laser welding of vehicle body[J]. Optics & Laser Technology, 2008, 40(2): 420-426.

[18] Luo Y, Tang X H, Lu F G. Experimental study on deep penetrated laser welding under local subatmospheric pressure[J]. The International Journal of Advanced Manufacturing Technology, 2014, 73(5/6/7/8): 699-706.

[19] Pang S Y, Chen L L, Zhou J X, et al. A three-dimensional sharp interface model for self-consistent keyhole and weld pool dynamics in deep penetration laser welding[J]. Journal of Physics D: Applied Physics, 2011, 44(2): 025301.

[20] Fabbro R, Hirano K, Pang S Y. Analysis of the physical processes occurring during deep penetration laser welding under reduced pressure[J]. Journal of Laser Applications, 2016, 28(2): 022427.

[21] 王欲知,

陈旭.

真空技术[M].

北京:

北京航空航天大学出版社,

2007:

39-

82.

Wang YZ,

ChenX.

Vacuum technology[M].

Beijing: Beijing University of Aeronautics and Astronautics press,

2007:

39-

82.

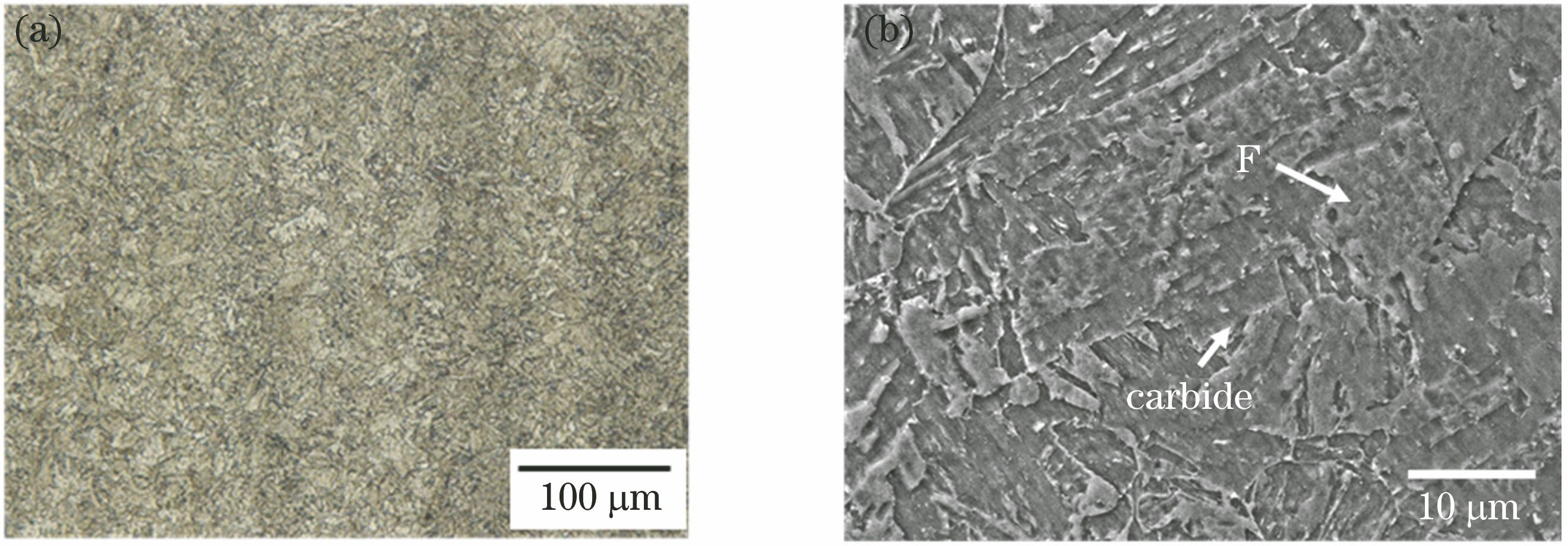

[22] Hu LH,

YanQ,

HuangJ,

et al. Microstructures and

mechanical properties on laser welded joints of automotive high strength complex phase steel[J]. Advanced Materials Research,

2010,

97/101:

3957-

3962.

[23] 沈保罗, 李莉, 岳昌林. 钢铁材料抗拉强度与硬度关系综述[J]. 现代铸铁, 2012, 32(1): 93-96.

Shen B L, Li L, Yue C L. Summarization of relationship between tensile strength and hardness of iron-steel materials[J]. Modern Cast Iron, 2012, 32(1): 93-96.

[24] 环鹏程, 王晓南, 朱天才, 等. 800 MPa级热轧高强钢激光焊接接头的组织性能研究[J]. 中国激光, 2019, 46(1): 0102002.

Huan P C, Wang X N, Zhu T C, et al. Microstructure and properties of laser welded joints of 800 MPa hot rolled high strength steel[J]. Chinese Journal of Lasers, 2019, 46(1): 0102002.

[25] 王金凤, 王立君, 杨立军, 等. DP1000高强钢激光焊接接头组织性能研究[J]. 中国激光, 2014, 41(9): 0903003.

Wang J F, Wang L J, Yang L J, et al. Research on microstructure and properties of laser welding DP1000 high-strength steel weld joints[J]. Chinese Journal of Lasers, 2014, 41(9): 0903003.

下载: 1446次

下载: 1446次