光学 精密工程, 2024, 32 (1): 125, 网络出版: 2024-01-23

集成视觉显著性和群决策的航空零件孔特征检测

Hole feature detection for aircraft parts by integrating visual saliency and group decision making

航空零件 孔特征检测 显著性检测 数学形态学 群决策 aircraft part hole feature detection saliency detection mathematical morphology group decision making

摘要

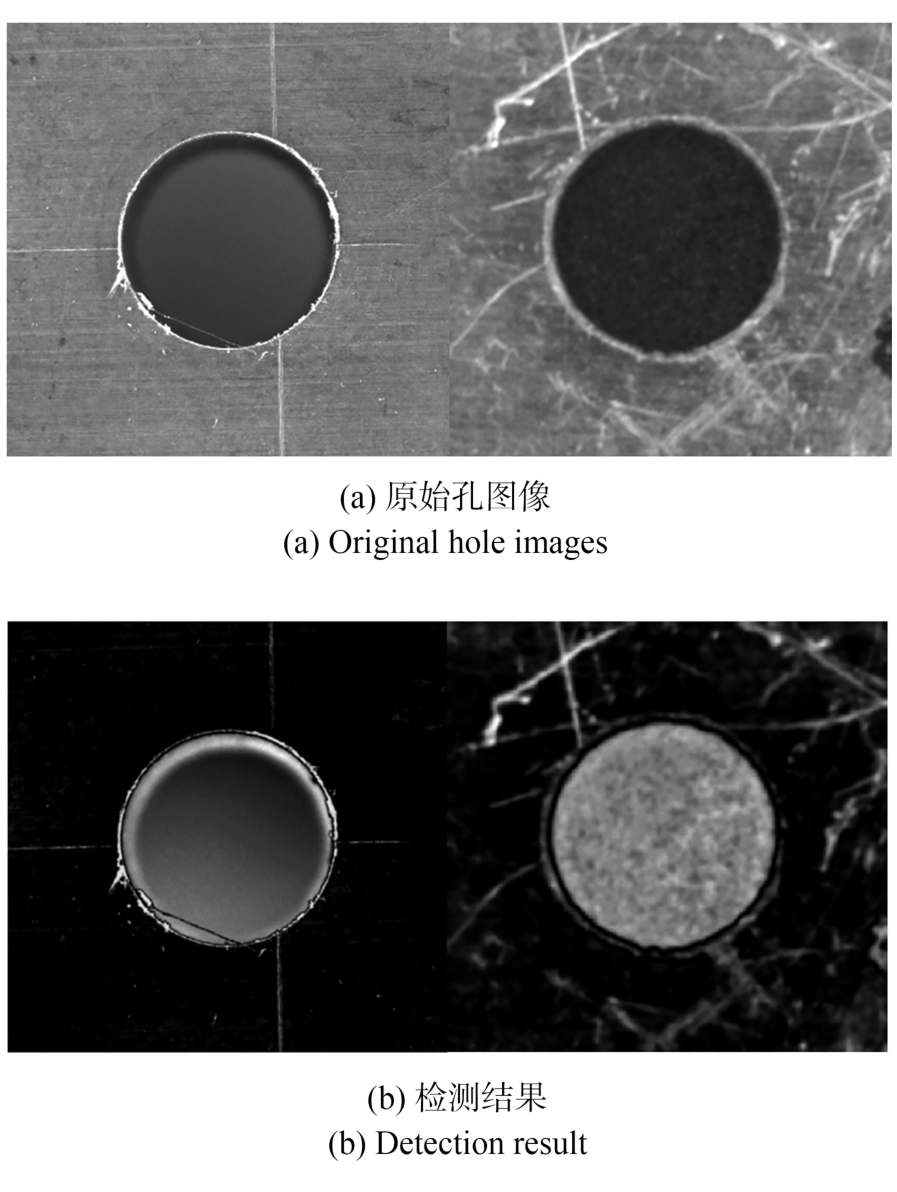

为了实现复杂环境下航空零件孔特征的高效高精度检测,提出了一种集成视觉显著性和群决策的检测方法。在经典FT显著性检测算法中引入图像增强步骤,并为每个像素赋予以最大显著区域中心为参考的权重,使用改进后的方法对图像进行孔区域分割。设计具有多尺度多结构元素的新型数学形态学边缘检测算法,结合轮廓细化算法对孔区域进行轮廓提取。最后,利用Meanshift算法寻找轮廓点的圆心位置,建立新的基于群决策的圆半径计算模型,获得孔特征的关键几何参数。结果表明:改进的视觉显著性特征检测算法能够生成更加突显孔特征的全分辨率显著图;新型数学形态学边缘检测算法能获得简化且可靠的轮廓点;该方法在不均匀光照、各类孔缺陷和孔内壁干扰等条件下均显示出较好的稳定性;即使在噪声密度高达30%时仍能成功完成孔检测,且圆心坐标和半径的误差均小于0.012 mm;平均检测时间仅为0.236 s。该方法能够在复杂环境下对航空零件孔特征进行准确、稳定的检测。

Abstract

A detection method integrating visual saliency and group decision making was proposed with the aim of achieving efficient and high-precision detection of hole features in aircraft parts in complex environments. First, an image enhancement step was incorporated into the classical frequency-tuned (FT) saliency detection algorithm, and each pixel was assigned a weight based on the center of the maximum saliency region. This improved method was used for hole region segmentation. Second, a novel mathematical morphological edge detection algorithm with multi-scale and multi-structural elements was designed. This algorithm was combined with contour thinning to extract hole contours. Finally, the centroid positions of the contour points were obtained using the Meanshift algorithm and a new model based on group decision making was established for calculating the hole radius, thus obtaining key geometric parameters of the hole features. The results show that the improved visual saliency feature detection algorithm generates higher-resolution saliency maps that highlight hole features more prominently. This novel mathematical morphological edge detection algorithm obtains simplified and reliable contour points. It also exhibits a high robustness under complex conditions, including uneven lighting, various types of hole defects, and interference from the hole interior. This method can still perform hole detection successfully even with a noise density of up to 30%, and the errors in the coordinates of the center and the radius are less than 0.012 mm. The average detection time is only 0.236 s. It can accurately and robustly detect hole features in aircraft parts in complex environments.

田佳淳, 王亮, 梅标, 朱伟东. 集成视觉显著性和群决策的航空零件孔特征检测[J]. 光学 精密工程, 2024, 32(1): 125. Jiachun TIAN, Liang WANG, Biao MEI, Weidong ZHU. Hole feature detection for aircraft parts by integrating visual saliency and group decision making[J]. Optics and Precision Engineering, 2024, 32(1): 125.