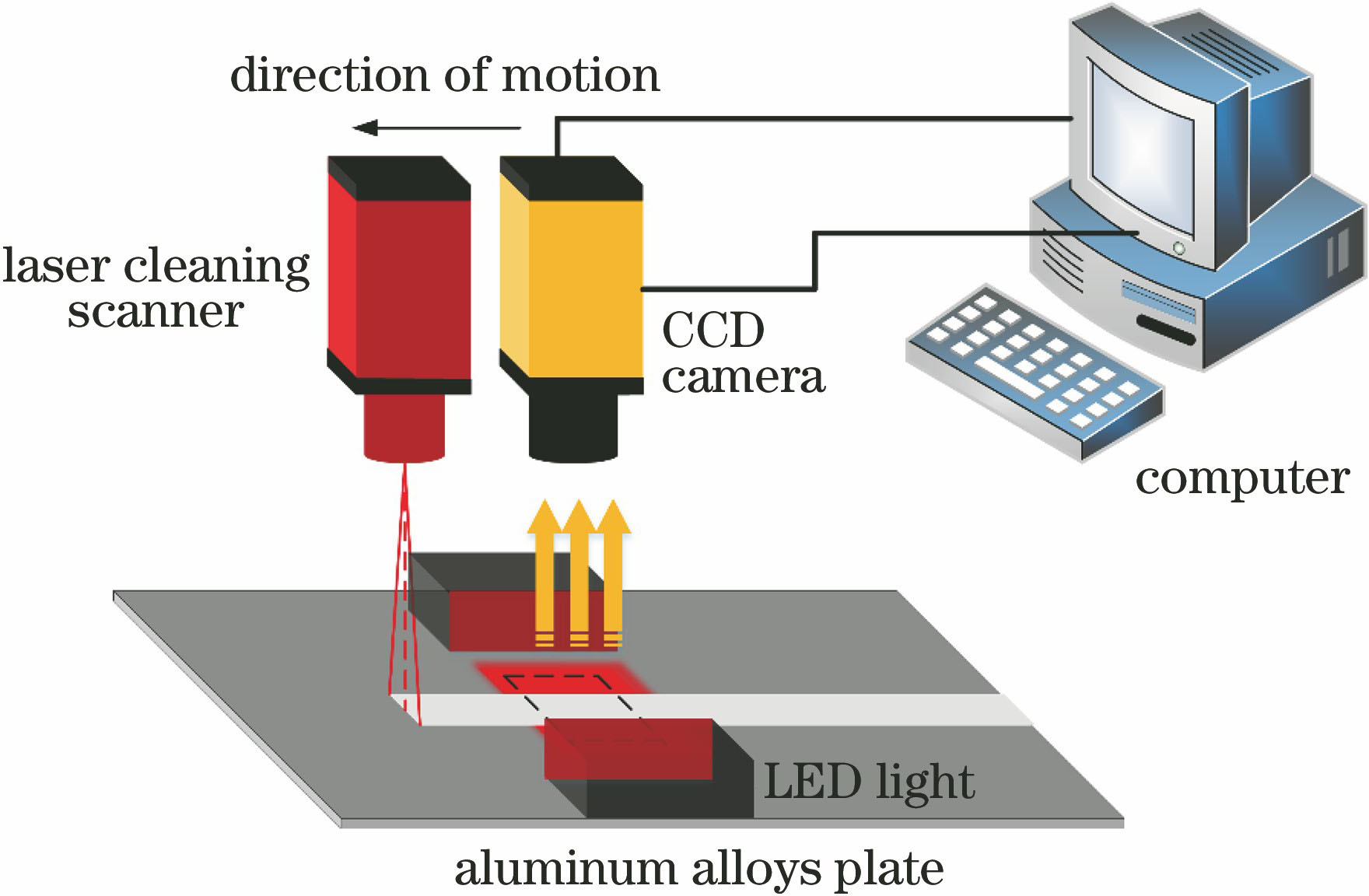

基于机器视觉的铝合金激光清洗实时检测系统  下载: 1196次

下载: 1196次

史天意, 周龙早, 王春明, 米高阳, 蒋平. 基于机器视觉的铝合金激光清洗实时检测系统[J]. 中国激光, 2019, 46(4): 0402007.

Tianyi Shi, Longzao Zhou, Chunming Wang, Gaoyang Mi, Ping Jiang. Machine Vision-Based Real-Time Monitor System for Laser Cleaning Aluminum Alloy[J]. Chinese Journal of Lasers, 2019, 46(4): 0402007.

[1] Lu Y F, Lee Y P, Hong M H, et al. Acoustic wave monitoring of cleaning and ablation during excimer laser interaction with copper surfaces[J]. Applied Surface Science, 1997, 119(1/2): 137-146.

[2] Whitehead D J, Crouse P L. Schmidt M J J, et al. Monitoring laser cleaning of titanium alloys by probe beam reflection and emission spectroscopy[J]. Applied Physics A: Materials Science & Processing, 2008, 93(1): 123-127.

[3] Klein S, Hildenhagen J, Dickmann K, et al. LIBS-spectroscopy for monitoring and control of the laser cleaning process of stone and medieval glass[J]. Journal of Cultural Heritage, 2000, 1: S287-S292.

[4] Lee J M, Watkins K G, Steen W M. In-process chromatic monitoring in the laser cleaning of marble[J]. Journal of Laser Applications, 2001, 13(1): 19-25.

[5] Khedr A, Papadakis V, Pouli P, et al. The potential use of plume imaging for real-time monitoring of laser ablation cleaning of stonework[J]. Applied Physics B, 2011, 105(2): 485-492.

[6] Tong Y Q, Shen Q, Cao M, et al. Acoustic monitoring during rust removal by dry laser cleaning[J]. International Journal of Nonlinear Science, 2013, 16(3): 225-229.

[7] 佟艳群, 张永康, 姚红兵, 等. 基于等离子体光强信号的激光除锈实时监测系统[J]. 中国激光, 2011, 38(10): 1003009.

[8] 陈康喜, 冯国英, 邓国亮, 等. 基于发射光谱及成分分析的激光除漆机理研究[J]. 光谱学与光谱分析, 2016, 36(9): 2956-2960.

[9] 郭吉昌, 朱志明, 于英飞, 等. 焊接领域激光结构光视觉传感技术的研究及应用[J]. 中国激光, 2017, 44(12): 1200001.

[10] 刘丹, 张斌, 李慧娴, 等. 复杂背景下微小圆柱端面缺陷检测方法研究[J]. 激光与光电子学进展, 2018, 55(6): 061006.

[11] 尹仕斌, 任永杰, 刘涛, 等. 机器视觉技术在现代汽车制造中的应用综述[J]. 光学学报, 2018, 38(8): 0815001.

[12] 岳彪, 闵永智, 马宏锋, 等. 基于改进Retinex的钢轨表面缺陷图像增强方法[J]. 兰州交通大学学报, 2018, 37(3): 42-48.

Yue B, Min Y Z, Ma H F, et al. Image enhancement method of rail surface defects based on improved Retinex[J]. Journal of Lanzhou Jiaotong University, 2018, 37(3): 42-48.

[13] 张驰, 谭南林, 李响, 等. 基于改进型Retinex算法的雾天图像增强技术研究[J]. 北京航空航天大学学报, 2019, 45(2): 309-316.

Zhang C, Tan N L, Li X, et al. Research on fog image enhancement technology based on improved Retinex algorithm[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(2): 309-316.

[14] 刘学林. 一种提高影像信息熵的图像预处理方法[J]. 测绘与空间地理信息, 2016, 39(7): 21-23, 26.

Liu X L. One method of image pretreatment to increase image's information entropy[J]. Geomatics & Spatial Information Technology, 2016, 39(7): 21-23, 26.

[15] 陈广锋, 管观洋, 魏鑫. 基于机器视觉的冲压件表面缺陷在线检测研究[J]. 激光与光电子学进展, 2018, 55(1): 011501.

[16] 何志勇, 孙立宁, 陈立国. Otsu准则下分割阈值的快速计算[J]. 电子学报, 2013, 41(2): 267-272.

He Z Y, Sun L N, Chen L G. Fast computation of threshold based on Otsu criterion[J]. Acta Electronica Sinica, 2013, 41(2): 267-272.

[17] 向守兵, 苏光大, 陈健生, 等. 基于机器视觉的码坯异常检测与识别[J]. 光学学报, 2011, 31(7): 0715002.

[18] 胡晓彤, 董莹莹. 基于机器视觉的金属罐内壁缺陷检测[J]. 天津科技大学学报, 2014, 29(3): 63-67.

Hu X T, Dong Y Y. Detecting defects of metal cans' inner wall based on machine vision[J]. Journal of Tianjin University of Science & Technology, 2014, 29(3): 63-67.

[19] 闵永智, 岳彪, 马宏锋, 等. 基于图像灰度梯度特征的钢轨表面缺陷检测[J]. 仪器仪表学报, 2018, 39(4): 220-229.

Min Y Z, Yue B, Ma H F, et al. Rail surface defects detection based on gray scale gradient characteristics of image[J]. Chinese Journal of Scientific Instrument, 2018, 39(4): 220-229.

史天意, 周龙早, 王春明, 米高阳, 蒋平. 基于机器视觉的铝合金激光清洗实时检测系统[J]. 中国激光, 2019, 46(4): 0402007. Tianyi Shi, Longzao Zhou, Chunming Wang, Gaoyang Mi, Ping Jiang. Machine Vision-Based Real-Time Monitor System for Laser Cleaning Aluminum Alloy[J]. Chinese Journal of Lasers, 2019, 46(4): 0402007.