激光与光电子学进展, 2017, 54 (1): 011407, 网络出版: 2017-01-17

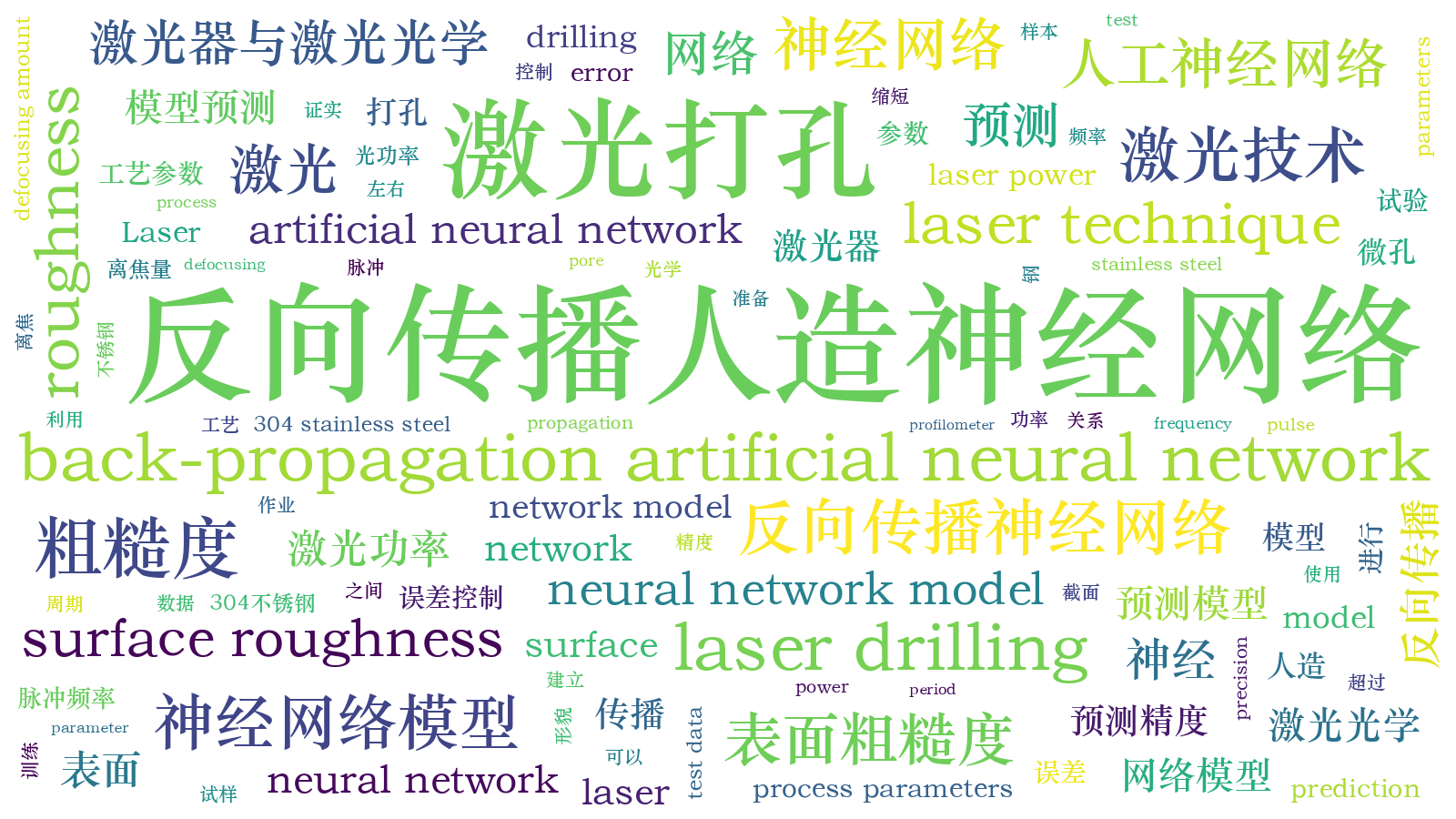

反向传播人造神经网络预测激光微孔表面粗糙度

Roughness Prediction of Laser Drilling Pore Surface Based on Back-Propagation Artificial Neural Networks

激光技术 反向传播人造神经网络 激光打孔 粗糙度 laser technique back-propagation artificial neural network laser drilling roughness

摘要

对304不锈钢试样进行了激光打孔试验, 使用形貌仪测得了孔截面粗糙度参数, 并通过反向传播神经网络, 建立了基于激光功率、脉冲频率和离焦量三个工艺参数与孔表面粗糙度之间关系的神经网络预测模型。利用大量试验数据对样本进行网络训练, 证实了该人工神经网络模型预测精度高, 预测误差控制在6%左右, 最大误差不超过8.08%。该模型可以准确地预测激光打孔表面的粗糙度和有效地缩短激光打孔作业的准备周期。

Abstract

The tests of laser drilling of 304 stainless steel specimens is conducted, the surface roughness parameter is obtained by the profilometer, and based on the back-propagation artificial neural network, the neural network prediction model based on the relationship between the three process parameters of laser power, pulse frequency, and defocusing amount, and the microporous surface roughness is established. After lots of network trainings with enough test data, it is confirmed that this artificial neural network model possesses a high prediction precision, the predication error is controlled around 6%, and the maximum error is less than 8.08%. This model can precisely predict the surface roughness of laser drilling pore surface, and effectively shorten the preparation period for laser drilling operations.

丁华, 李炎蔚, 袁冬青. 反向传播人造神经网络预测激光微孔表面粗糙度[J]. 激光与光电子学进展, 2017, 54(1): 011407. Ding Hua, Li Yanwei, Yuan Dongqing. Roughness Prediction of Laser Drilling Pore Surface Based on Back-Propagation Artificial Neural Networks[J]. Laser & Optoelectronics Progress, 2017, 54(1): 011407.