中国激光, 2018, 45 (3): 0302008, 网络出版: 2018-03-20

热变形条件对激光增材制造TC18钛合金组织及变形行为的影响  下载: 1087次

下载: 1087次

Effects of Thermal Deformation Conditions on Microstructures and Deformation Behaviors of Laser Additive Manufactured TC18 Titanium Alloys

激光技术 激光增材制造 TC18钛合金 热变形 热加工图 laser technique laser additive manufacturing TC18 titanium alloy thermal deformation thermal processing map

摘要

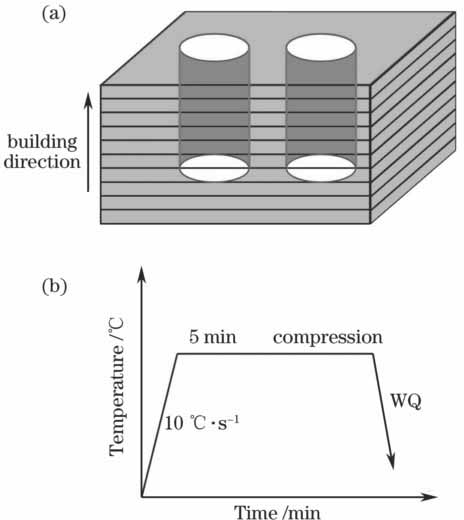

通过单轴等温热压缩实验,研究了激光增材制造TC18钛合金在不同变形条件下的热变形行为,分析了其流变应力-应变规律和动态软化机制,建立了峰值应力本构方程。结果表明,激光增材制造TC18钛合金的流变应力-应变曲线表现为连续软化和稳态流变两种特征,其激活能为476.8 kJ·mol-1。当热加工温度处于α+β两相区时,软化机制为动态回复;而当热加工温度处于β单相区时,软化机制为动态再结晶。激光增材制造TC18钛合金较理想的热加工工艺参数:变形温度为830~880 ℃、应变速率为0.001~0.003 s-1和变形温度为750~760 ℃、应变速率为0.001~0.002 s-1。

Abstract

By means of the uniaxial isothermal compression test, the thermal deformation behaviors of laser additive manufactured TC18 titanium alloys are studied under different thermal deformation conditions. The regularity of flow stress-strain and softening mechanism are analyzed. The constitutive equation of peak stress is established. The results show that the flow stress-strain curves of laser additive manufactured TC18 titanium alloys can be characterized by two kinds of characteristics of the continuous softening and the steady rheology, and the activation energy is 476.8 kJ·mol-1. When the thermal working temperature is in the α+β two-phase region, the softening mechanism is mainly the dynamic recovery; when the thermal working temperature is in the β single phase region, the softening mechanism is the dynamic recrystallization. The ideal thermal process parameters for laser additive manufactured TC18 titanium alloys are the defomation temperature of 830-880 ℃ and the strain rate of 0.001-0.003 s-1, or the deformation temperature of 750-760 ℃ and the strain rate of 0.001-0.002 s-1.

王宏芳, 田象军, 程序, 刘栋, 王华明. 热变形条件对激光增材制造TC18钛合金组织及变形行为的影响[J]. 中国激光, 2018, 45(3): 0302008. Wang Hongfang, Tian Xiangjun, Cheng Xu, Liu Dong, Wang Huaming. Effects of Thermal Deformation Conditions on Microstructures and Deformation Behaviors of Laser Additive Manufactured TC18 Titanium Alloys[J]. Chinese Journal of Lasers, 2018, 45(3): 0302008.