光学学报, 2018, 38 (10): 1014002, 网络出版: 2019-05-09

激光冲击强化H62黄铜摩擦磨损性能研究  下载: 817次

下载: 817次

Friction and Wear Properties of H62 Brass Subjected to Laser Shock Peening

摘要

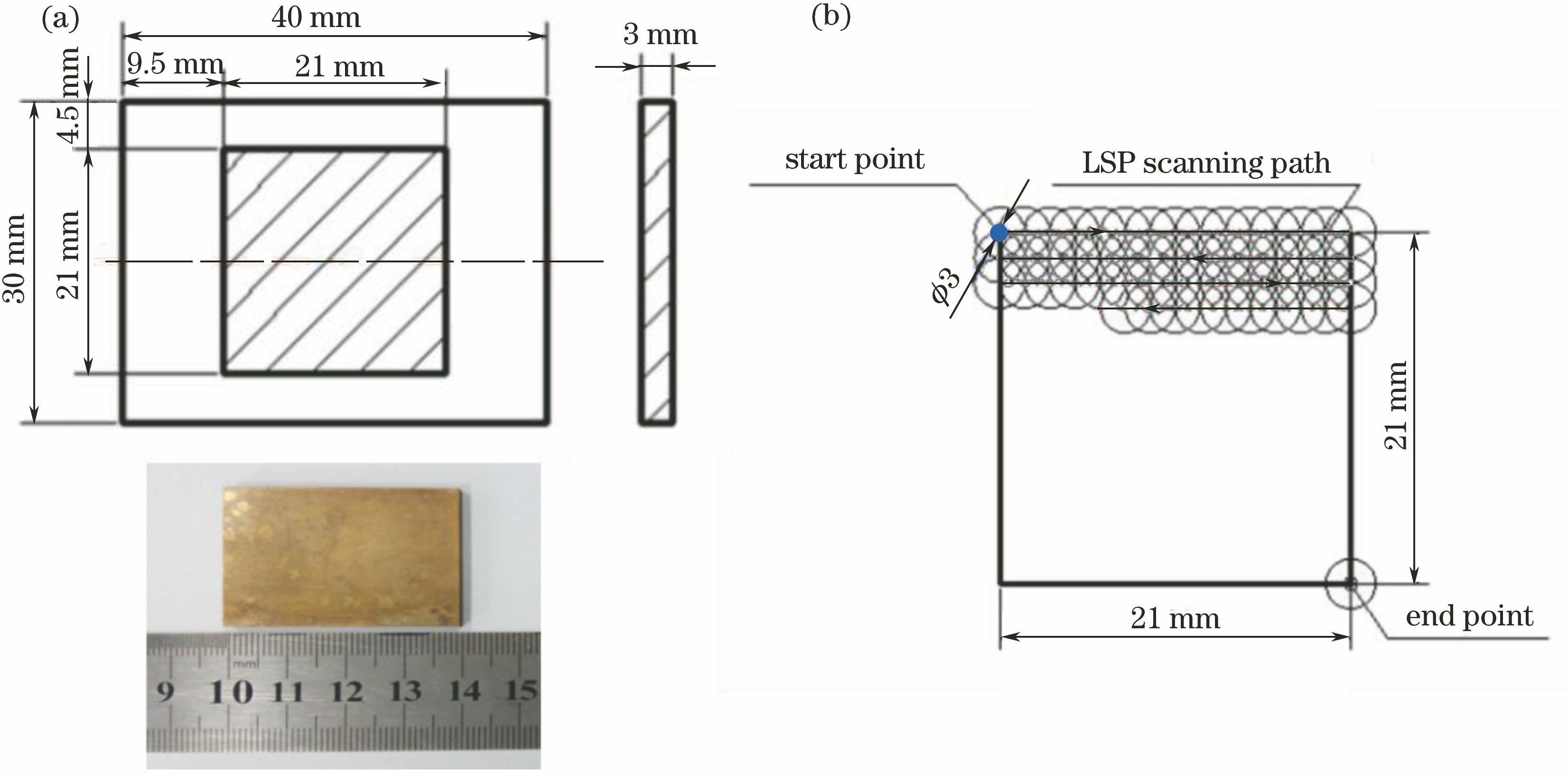

采用高能激光束对H62黄铜进行单层和三层激光冲击强化(LSP),研究激光冲击前后微观组织、截面显微硬度以及表面粗糙度的变化,发现激光冲击明显细化了H62黄铜的晶粒,形成纳米结构层,并增加了其显微硬度和表面粗糙度,且显微硬度和表面粗糙度随冲击层数的增加而增大。利用UMT-2摩擦磨损实验机分别对原始试样、LSP试样进行摩擦磨损实验,分析了三种试样的摩擦系数、磨损率和磨痕形貌差异,发现在相同的摩擦条件下,LSP试样的摩擦系数和磨损率均比原始试样小,且随着冲击层数从单层增加到三层,摩擦系数和磨损量变得更小,表明LSP能够提高H62黄铜的耐磨性,多层LSP对H62黄铜耐磨性的提升效果更佳。激光冲击后,试样的磨损机制由以剥层磨损为主转变为以磨粒磨损为主。

Abstract

H62 brass is subjected to laser shock peening (LSP) with one coverage layer and three coverage layers by high-energy laser beam. Varieties of micro-structure, micro-hardness, and surface roughness before and after LSP are investigated. It is found that the grain size of H62 brass is obviously refined with LSP, and a nanostructure layer is obtained. The micro-hardness and surface roughness of H62 brass increase with the increase of number of LSP coverage layers. The friction and wear test of the as-received sample and LSPed samples (samples subjected to LSP) is carried out by UMT-2 friction and wear test machine. The differences of friction coefficient, wear rate, and wear scar morphology in these samples are analyzed. It is found that under the same friction condition, the friction coefficient and wear rate of LSPed samples are smaller than the as-received sample, which become much smaller with the LSP coverage layers increasing from one to three. It is indicated that LSP can improve the wear resistance of H62 brass, and multi-layer LSP has a better effect on the improvement of the wear resistance of H62 brass. After LSP, the wear mechanism is changed from domination with delamination wear to abrasive wear.

段海峰, 罗开玉, 鲁金忠. 激光冲击强化H62黄铜摩擦磨损性能研究[J]. 光学学报, 2018, 38(10): 1014002. Haifeng Duan, Kaiyu Luo, Jinzhong Lu. Friction and Wear Properties of H62 Brass Subjected to Laser Shock Peening[J]. Acta Optica Sinica, 2018, 38(10): 1014002.