Chinese Optics Letters, 2018, 16 (10): 101402, Published Online: Oct. 12, 2018

Thermal process of silica glass microchannels fabricated by femtosecond laser ablation  Download: 895次

Download: 895次

Abstract

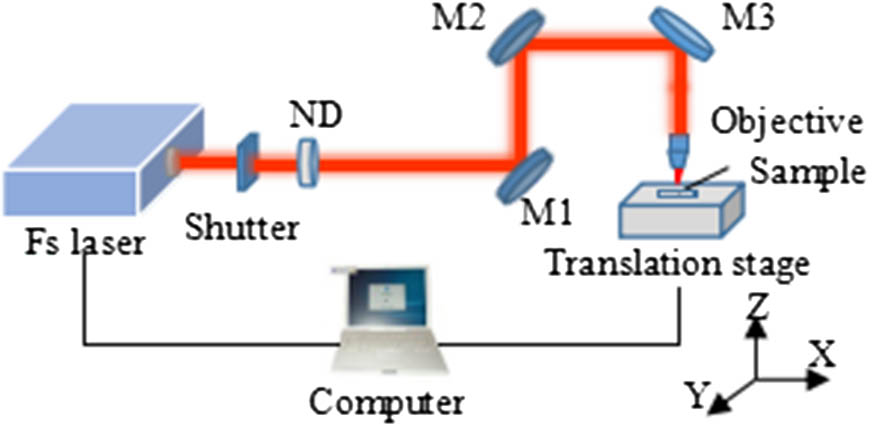

In order to improve the morphology of microchannels fabricated by femtosecond laser ablation, the thermal process was introduced into the post-treatment processing. It was found that the thermal process cannot only decrease the roughness but also the width and depth of the microchannel. The change rates of width, depth, and roughness of the microchannel increase with processing temperature. When we prolong the time of constant temperature, the change rate of the width decreases at the beginning, and then it tends to be stable. However, the change rates of depth and roughness increase, and then they tend to be stable. In this Letter, we discuss the reasons of the above phenomena.

Xiaoyan Sun, Dongmei Cui, Youwang Hu, Dongkai Chu, Guowei Chen, Jinlong Yu, Jianhang Zhou, Ji’an Duan. Thermal process of silica glass microchannels fabricated by femtosecond laser ablation[J]. Chinese Optics Letters, 2018, 16(10): 101402.