中国激光, 2018, 45 (12): 1202012, 网络出版: 2019-05-09

激光熔覆制备马氏体/铁素体双相不锈钢层的力学与腐蚀性能研究  下载: 899次

下载: 899次

Mechanical and Corrosion Properties of Martensite/Ferrite Duplex Stainless Steel Prepared via Laser Cladding

激光技术 激光熔覆 马氏体/铁素体双相不锈钢 微量硼元素 显微组织 高性能 laser technique laser cladding martensite/ferrite duplex stainless steel trace boron element microstructure high properties

摘要

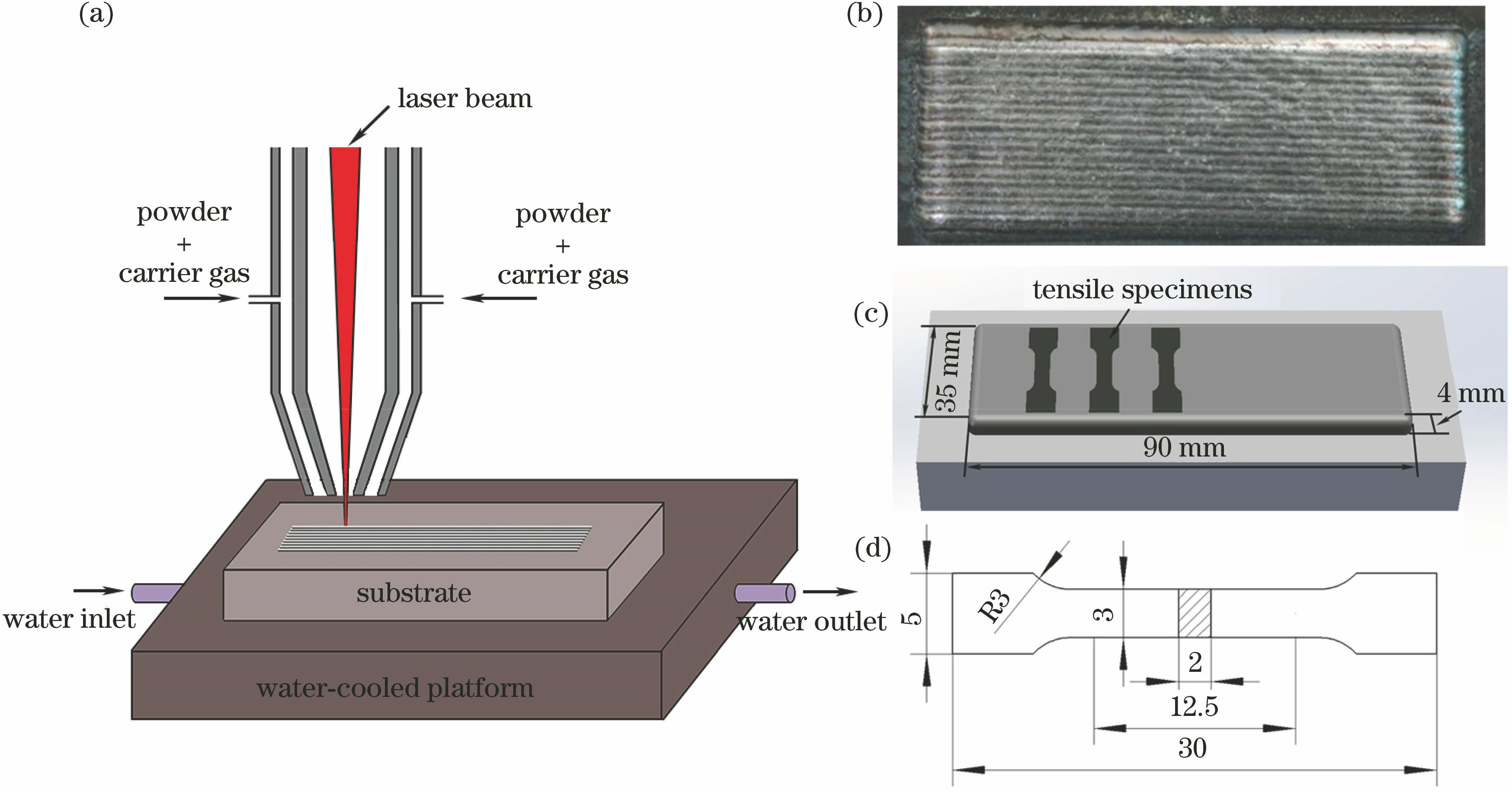

为了获得高强度、高韧性、耐蚀性好的铁基合金涂层,在Q235基体上激光熔覆了含微量硼元素的低碳、低合金马氏体/铁素体双相不锈钢(M/Fss)合金粉末。研究结果表明,所制备的激光熔覆层表面具有金属光泽,内部无夹杂、气孔等缺陷。熔覆层由马氏体、铁素体、主要沿枝晶间呈均匀不连续分布的硼碳化物M (B,C)和少量在枝晶内析出的M 23(B,C)6组成(M 为Fe、Cr等)。熔覆层力学性能优异,平均显微硬度为431.9 HV,抗拉强度为1352 MPa,延伸率为12.3%,且耐腐蚀性能优于1Cr13马氏体不锈钢。这一新型的M/Fss涂层可广泛应用于同时对力学性能和耐蚀性能要求高的工作环境下的铁基材料表面改性或再制造。

Abstract

This study aims to obtain a Fe-based alloy coating with high strength, high toughness, and good corrosion resistance. Therefore, a novel low-carbon and low-alloy martensite/ferrite dual-phase stainless steel (M/Fss) powder with trace addition of boron is cladded on Q235 steel by the laser cladding technique. The research results reveal that the surface of the laser cladding coating has metallic luster, and there are no inclusions and pores in the coating. The coating is constituted of martensite, ferrite, and boron carbides M(B,C) with uniform and discontinuous distribution along the dendrite (M represents Fe, Cr, etc.). A few M23(B,C)6 particles precipitated within the dendrite. The cladding layer exhibits excellent mechanical properties, including average hardness of 431.9 HV, tensile strength of 1352 MPa, and ductility of 12.3%. Its superior corrosion resistance is better than that of 1Cr13 martensite stainless steel. This new type of M/Fss coating can be widely used for surface modification or remanufacturing of Fe-based materials in working environments requiring mechanical and corrosion resistances.

朱红梅, 李勇作, 张振远, 何彬, 邱长军. 激光熔覆制备马氏体/铁素体双相不锈钢层的力学与腐蚀性能研究[J]. 中国激光, 2018, 45(12): 1202012. Hongmei Zhu, Yongzuo Li, Zhenyuan Zhang, Bin He, Changjun Qiu. Mechanical and Corrosion Properties of Martensite/Ferrite Duplex Stainless Steel Prepared via Laser Cladding[J]. Chinese Journal of Lasers, 2018, 45(12): 1202012.