中国激光, 2019, 46 (3): 0302009, 网络出版: 2019-05-09

GCr15轴承钢表面的激光凹/凸微织构工艺  下载: 999次

下载: 999次

Laser Concave/Convex Micro-Texture Process of GCr15 Bearing Steel Surface

摘要

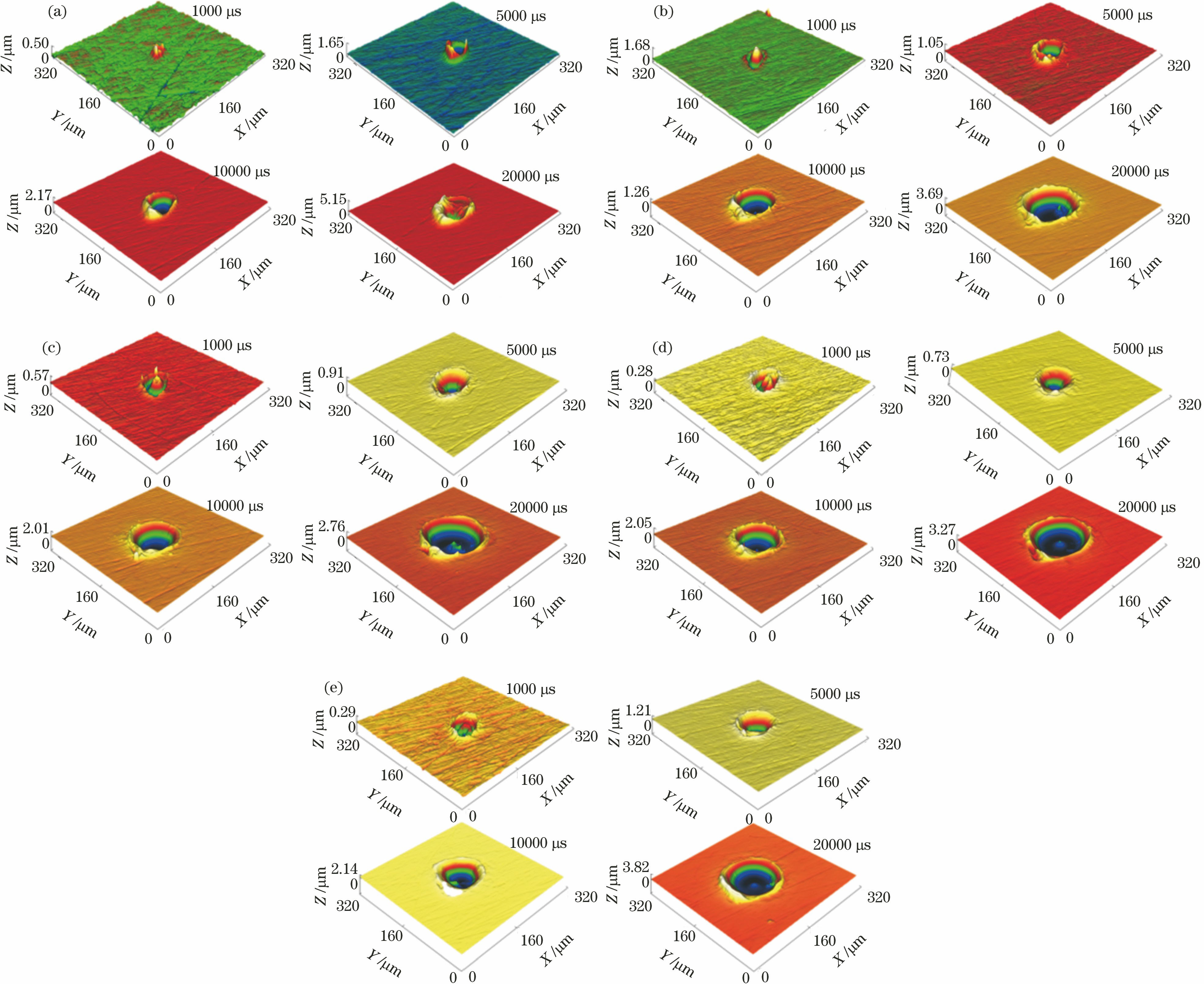

采用光纤激光器对GCr15轴承钢试样表面进行了激光织构加工,使用共聚焦显微镜观察了微织构的形貌,分析了功率、脉宽、重复次数对织构点形貌的影响。试验结果表明,织构点直径随脉宽的增大而增大,在一定脉宽范围内,织构点深度随脉宽的增大而明显增大;在单脉冲作用下,当脉宽为1000 μs时形成凸起形貌,当脉宽增大到5000 μs以上时形成凹坑形貌;随着功率的增大,织构点的直径和深度增大;随着重复次数的增加,热效应尤为明显,凹坑先逐渐变深然后部分被填平,凸起高度先不变然后急剧增大。研究验证了同一台激光器同时实现凹/凸微织构的可行性,为实现表面不同形貌的加工提供了新的思路。

Abstract

Laser texture process is carried out on the surface of GCr15 bearing steel by a fiber laser and the morphology of micro texture is observed by the confocal microscope. The effects of power, pulse width and repetition times on texture morphology are analyzed. The experimental results show that with the increment of pulse width, the diameter of textured point increases and the depth of textured point significantly increases in a certain range of pulse width. Under the condition of single pulse,when the pulse width is 1000 μs, textured structure forms a convex profile, and when the pulse width increases to be more than 5000 μs, textured structure forms a concave pit. With the increment of laser power, the diameter and depth of the textured point increase. The heat effect is more obvious with the increase of repetition times. The pit is gradually deepened and then partially filled up. The height of the convex profile is firstly almost invariable and then rapidly increases. The study verifies the feasibility of the same laser to realize concave or convex micro textures simultaneously, and also provides new ideas for processing different surface topography.

华希俊, 张加力, 解玄, 平国峰, 张玲慧, 尹必峰. GCr15轴承钢表面的激光凹/凸微织构工艺[J]. 中国激光, 2019, 46(3): 0302009. Xijun Hua, Jiali Zhang, Xuan Xie, Guofeng Ping, Huiling Zhang, Bifeng Yin. Laser Concave/Convex Micro-Texture Process of GCr15 Bearing Steel Surface[J]. Chinese Journal of Lasers, 2019, 46(3): 0302009.