中国激光, 2019, 46 (3): 0302005, 网络出版: 2019-05-09

扫描速率对激光熔覆Cu80Fe20偏晶涂层组织与耐磨性能的影响  下载: 844次

下载: 844次

Effects of Scanning Speed on Microstructure and Wear Resistance of Cu80Fe20 Immiscible Coatings Prepared by Laser Cladding

激光技术 激光熔覆 扫描速率 Cu-Fe合金 偏晶涂层 液相分离 冷却速率 耐磨性能 laser technique laser cladding scanning speed Cu-Fe alloy immiscible coatings liquid-phase separation cooling rate wear resistance

摘要

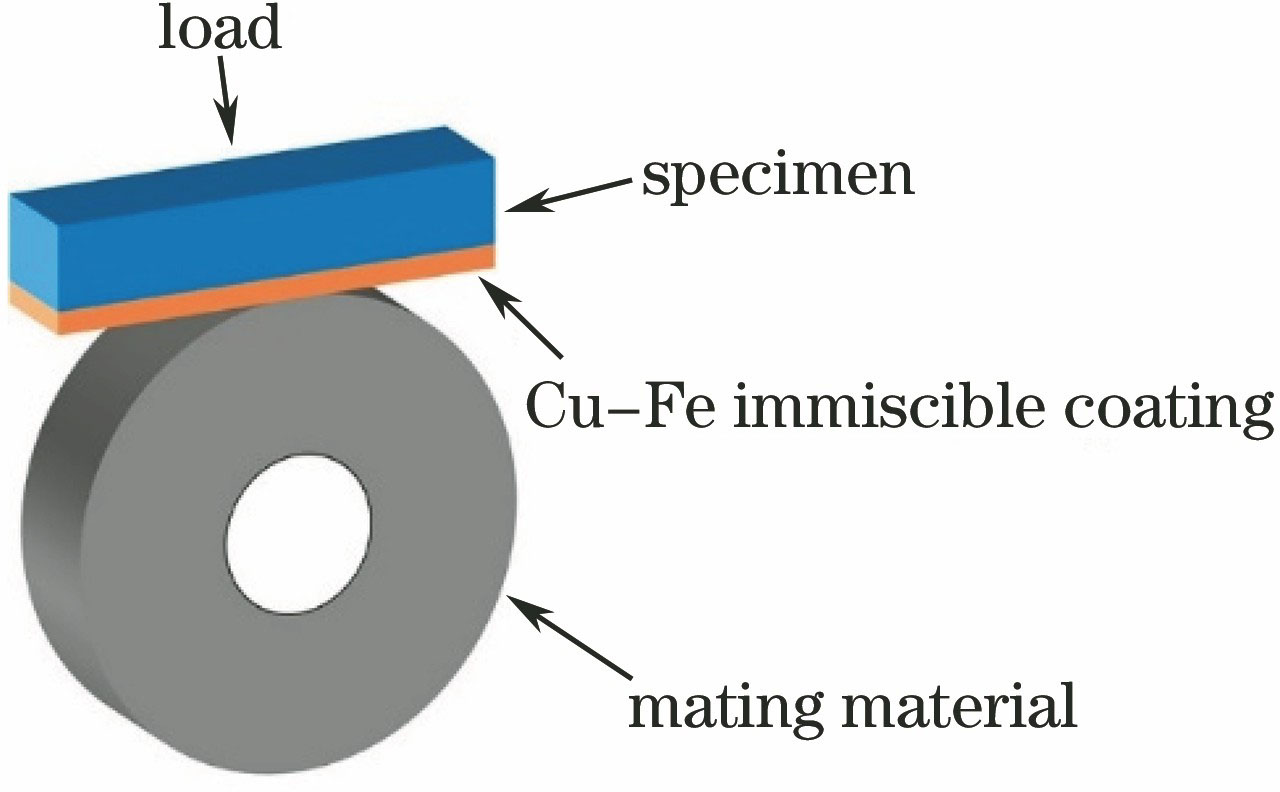

采用激光熔覆技术制备了Cu80Fe20偏晶涂层,研究了扫描速率对液相分离特征以及偏晶涂层显微硬度、耐磨性能的影响。研究结果表明: Cu80Fe20偏晶涂层内出现了分层现象,大量由体心立方结构α-Fe、面心立方结构γ-Fe组成的富铁颗粒弥散分布于上层的面心立方ε-Cu基体内,大量面心立方ε-Cu富铜颗粒分布于下层的α-Fe基体内;随着激光扫描速率增大,激光熔池的冷却速率增大,富铁颗粒粒径逐渐减小,面密度逐渐增大,相邻富铁颗粒间的间距减小,富铁颗粒对铜基体的阴影保护效应增强,使得偏晶涂层的显微硬度与耐磨性能增加,且均优于黄铜。

Abstract

The Cu80Fe20 immiscible coating is fabricated by laser cladding technique and the effects of scanning speed on the liquid phase separation characteristics, microhardness and wear resistance of the immiscible coating are investigated. The research results indicate that the delamination phenomenon appears in the Cu80Fe20 immiscible coatings; a large amount of Fe-rich particles consist of body-centered-cubic (bcc) α-Fe, face-centered-cubic (fcc) γ-Fe are dispersed in the upper fcc ε-Cu matrix, and a large amount of ε-Cu Cu-rich particles are distributed in the lower α-Fe matrix. With the increase of the laser scanning speed, the cooling rate of the molten pool increases and the size of Fe-rich particles decreases, while the surface density of Fe-rich particles increases, the spacing of neighbouring Fe-rich particles decreases, and therefore the shadow protection effect of Fe-rich particles on the Cu-rich matrix is enhanced, leading to the improvement in microhardness and wear resistance of the immiscible coating, which are both higher than those of brass.

赵淑珍, 金剑波, 谢敏, 许永波, 戴晓琴, 周圣丰. 扫描速率对激光熔覆Cu80Fe20偏晶涂层组织与耐磨性能的影响[J]. 中国激光, 2019, 46(3): 0302005. Shuzhen Zhao, Jianbo Jin, Min Xie, Yongbo Xu, Xiaoqin Dai, Shengfeng Zhou. Effects of Scanning Speed on Microstructure and Wear Resistance of Cu80Fe20 Immiscible Coatings Prepared by Laser Cladding[J]. Chinese Journal of Lasers, 2019, 46(3): 0302005.