激光与光电子学进展, 2019, 56 (10): 101404, 网络出版: 2019-07-04

不同热处理状态的Ti2AlNb合金激光焊接接头组织与性能

Microstructures and Properties of Laser Welded Ti2AlNb-Based Alloy Joints Under Different Heat Treatment States

激光光学 激光焊接 Ti2AlNb基合金 热处理状态 微观组织 力学性能 laser optics laser welding Ti2AlNb-based alloy heat treatment states microstructure mechanical properties

摘要

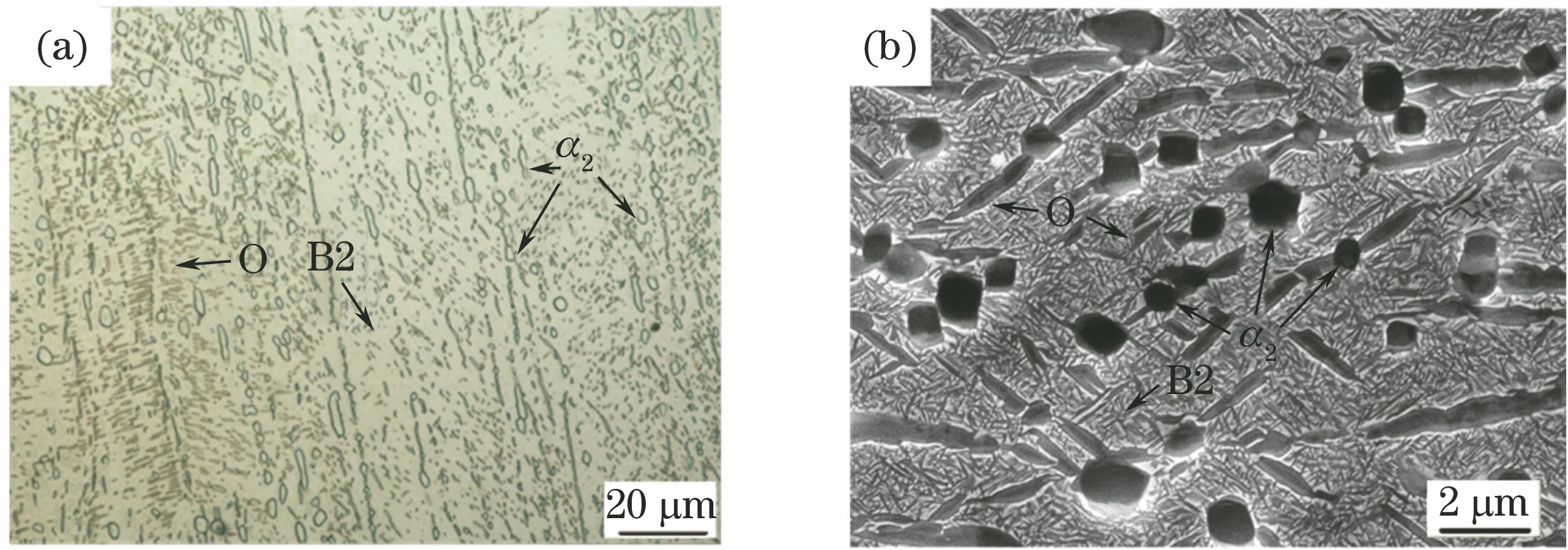

研究了热轧态、1080 ℃/40 min/水冷热处理(HT1)和980 ℃/3 h/油冷热处理(HT2)Ti-22Al-27Nb合金板材的激光焊接接头组织与力学性能。在激光功率为1500 W、焊接速度为1 m/min的工艺参数下得到成形良好的焊缝。热轧态、HT1和HT2板材的组织分别为B2+O+α2相、B2相、B2+O+α2相。热轧态和HT2板材接头的热影响区组织从熔合线到母材方向依次为B2相区、B2+α2相区和B2+O+α2相区,而HT1板材接头的热影响区组织为单一的B2相。热轧态板材接头在室温和650 ℃下的抗拉强度分别为1023 MPa和675 MPa,延伸率分别为5.48%和2.56%, 而HT2板材接头的抗拉强度分别为860 MPa和680 MPa,延伸率分别为7.04%和4.97%。

Abstract

The microstructures and mechanical properties of laser welded Ti-22Al-27Nb alloy sheet joints are investigated under hot rolling, heat treatment of 1080 ℃/40 min/water-cooling (HT1), and heat treatment of 980 ℃/3 h/oil-cooling (HT2). The well-formed welds are obtained with the process parameters of laser power of 1500 W and welding speed of 1 m/min. The microstructures of hot rolled, HT1 and HT2 sheet joints are B2+O+α2 phase, B2 phase, and B2+O+α2 phase, respectively. From the fusion line to the base metal, the microstructures of heat affected zones for hot rolled and HT2 sheet joints are the B2, B2+α2, and B2+O+α2 phase zones, respectively, however, those of HT1 sheet joints are only single B2 phase. The tensile strengths of hot rolled sheet joints at room temperature and 650 ℃ are 1023 MPa and 675 MPa, and the elongations are 5.48% and 2.56%, respectively. In contrast, the tensile strength of HT2 sheet joints are 860 MPa and 680 MPa, and the elongations are 7.04% and 4.97%, respectively.

刘博, 雷正龙, 周恒, 汪宏辉. 不同热处理状态的Ti2AlNb合金激光焊接接头组织与性能[J]. 激光与光电子学进展, 2019, 56(10): 101404. Bo Liu, Zhenglong Lei, Heng Zhou, Honghui Wang. Microstructures and Properties of Laser Welded Ti2AlNb-Based Alloy Joints Under Different Heat Treatment States[J]. Laser & Optoelectronics Progress, 2019, 56(10): 101404.