中国激光, 2019, 46 (5): 0502003, 网络出版: 2019-11-11

体激光能量密度对选区激光熔化316L不锈钢各向异性的影响  下载: 1034次

下载: 1034次

Effects of Bulk Laser Energy Density on Anisotropy of Selective Laser Sintered 316L Stainless Steel

材料 选区激光熔化 各向异性 316L不锈钢 体激光能量密度 显微组织 materials selective laser melting anisotropy 316L stainless steel bulk laser energy density microstructure

摘要

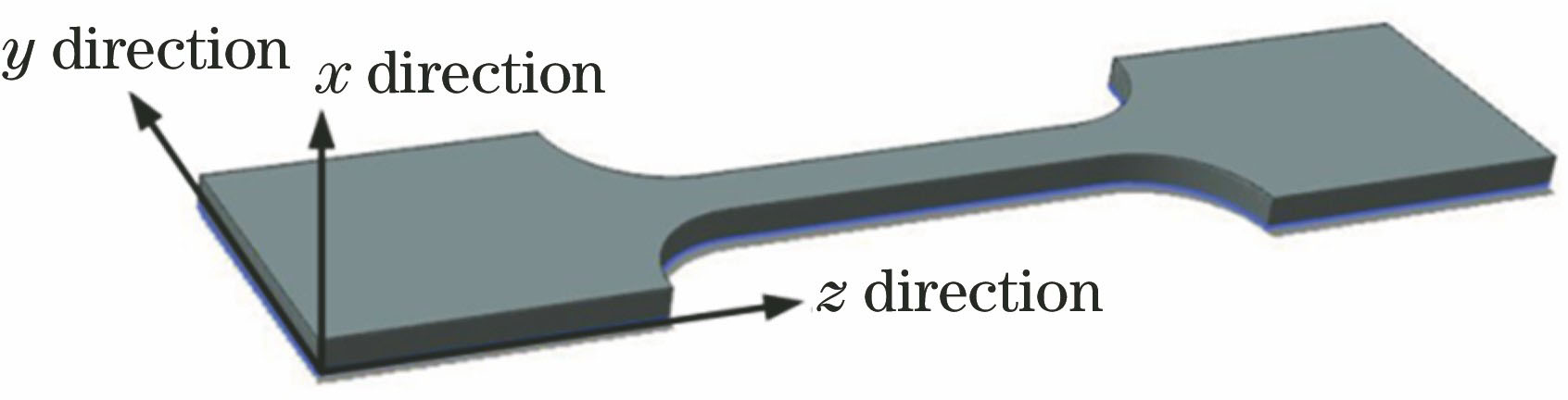

在激光旋转角度为73°,粉层厚度为30 μm的条件下,采用选区激光熔化工艺快速成形316L不锈钢,研究了体激光能量密度及成形方向对成形件组织、性能各向异性的影响。结果表明:成形方向对力学性能的影响极大,力学性能的各向异性随组织的各向异性而变;随着体激光能量密度增加,熔池表面趋于平整,x和y向成形件的晶粒生长方向单一,z向成形件的晶粒生长取向明显;当体激光能量密度为65~85 J·mm -3时,晶体生长方向与堆积方向一致,抗拉强度和断后伸长率最佳。可以利用体激光能量密度控制成形件的组织及性能。

Abstract

Selective laser melting (SLM) is used to rapidly form 316L stainless steels formed when the laser rotation angle is 73° and the powder layer is 30-μm thick, and the effects of bulk laser energy density and forming direction on the anisotropy of microstructure and mechanical properties of the formed parts are studied. The results show that the forming direction has a great influence on the mechanical properties, and the anisotropy of the mechanical property varies with the anisotropy of the microstructure. As the bulk laser energy density increases, the surface of the molten pool tends to be flat, the grain growth directions of formed part become singular in the x and y directions, and the grain growth direction of formed part in the z direction is obviously orientation-dependent. When the bulk laser energy density is 65-85 J·mm -3, the crystal growth direction is well aligned with the stacking direction, and the tensile strength and the percentage elongation after fracture are optimal. Therefore, the bulk laser energy density can be used for controlling the microstructure and mechanical properties of formed parts.

宗学文, 高倩, 周宏志, 张佳亮, 齐腾博. 体激光能量密度对选区激光熔化316L不锈钢各向异性的影响[J]. 中国激光, 2019, 46(5): 0502003. Xuewen Zong, Qian Gao, Hongzhi Zhou, Jialiang Zhang, Tengbo Qi. Effects of Bulk Laser Energy Density on Anisotropy of Selective Laser Sintered 316L Stainless Steel[J]. Chinese Journal of Lasers, 2019, 46(5): 0502003.