激光与光电子学进展, 2019, 56 (23): 231404, 网络出版: 2019-11-27

纳秒脉冲激光铣削Al2O3陶瓷工艺参数的优化  下载: 874次

下载: 874次

Process Parameter Optimization of Al2O3 Ceramics Milled with Nanosecond Pulsed Laser

激光技术 激光铣削 Al2O3陶瓷 响应面法 工艺参数优化 laser technique laser milling Al2O3 ceramics response surface method optimization of process parameters

摘要

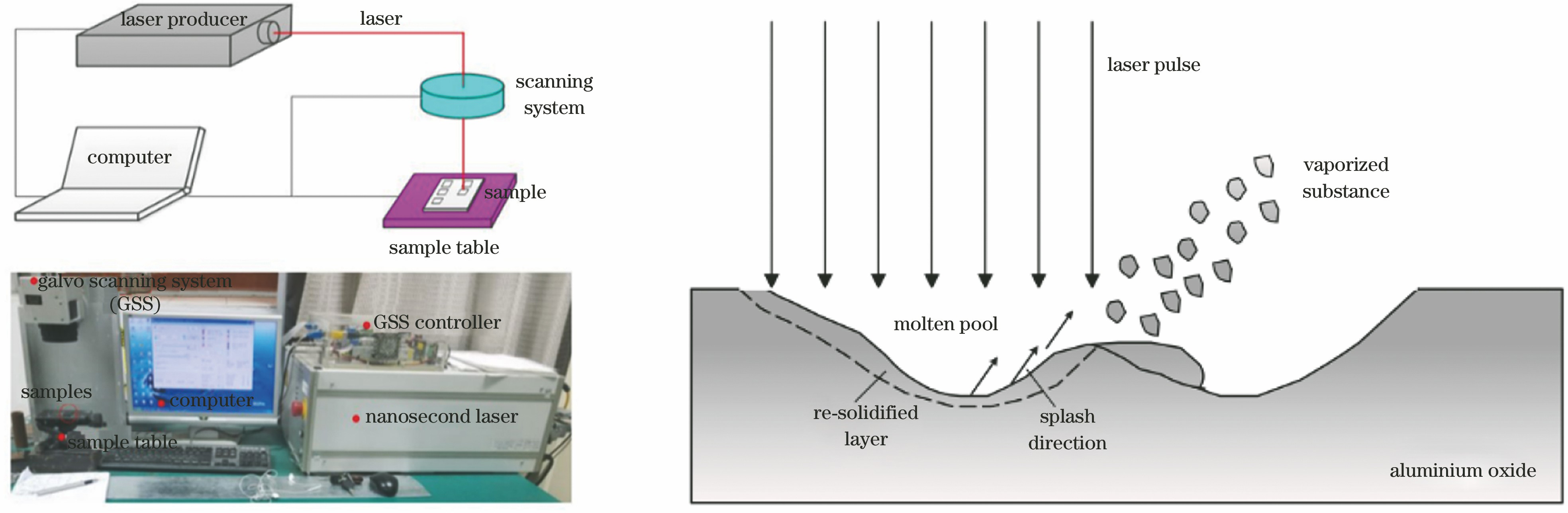

采用纳秒脉冲激光对Al2O3陶瓷进行激光铣削实验。使用响应面二阶回归模型建立铣削工艺参数与表面粗糙度、铣削深度之间的变化关系,通过灵敏度分析方法识别影响表面粗糙度和铣削深度的关键工艺参数;以最小化表面粗糙度和最大化铣削深度为优化目标,利用遗传算法确定理想的工艺参数组合,并进行实验验证。结果表明:基于响应面法的数学模型预测能力较强,铣削次数及搭接率对表面粗糙度和铣削深度的影响最为显著,优化参数下表面粗糙度与铣削深度的预测值分别为10.471 μm和120.526 μm,实验值分别为10.835 μm和131.277 μm,相对误差分别为3.36%和8.19%。

Abstract

Herein, laser milling of Al2O3 ceramics is conducted using nanosecond pulsed laser. The relationship among milling process parameters, surface roughness, and milling depth is investigated using response surface second-order regression model. In addition, the key process parameters affecting surface roughness and milling depth are identified using sensitivity analysis. A genetic algorithm is used to determine the optimal process parameters that minimize the surface roughness and maximize the milling depth. These parameters are then experimentally verified. Results indicate a strong predictive ability of the mathematical model based on the response surface method. The number of milling times and overlap rate have the most significant effect on the surface roughness and milling depth. Under optimized parameters, the predicted surface roughness and milling depth are found to be 10.471 μm and 120.526 μm, respectively, while their corresponding experimental values are 10.835 μm and 131.277 μm, respectively. Therefore, the relative errors in case of surface roughness and milling depth are only 3.36% and 8.19%, respectively.

许兆美, 孟宪凯, 屈彦荣, 朱为国, 郭召恒. 纳秒脉冲激光铣削Al2O3陶瓷工艺参数的优化[J]. 激光与光电子学进展, 2019, 56(23): 231404. Zhaomei Xu, Xiankai Meng, Yanrong Qu, Weiguo Zhu, Zhaoheng Guo. Process Parameter Optimization of Al2O3 Ceramics Milled with Nanosecond Pulsed Laser[J]. Laser & Optoelectronics Progress, 2019, 56(23): 231404.