中国激光, 2019, 46 (10): 1002010, 网络出版: 2019-10-25

超高速激光熔覆与常规激光熔覆431不锈钢涂层微观组织和耐蚀性的对比  下载: 1703次

下载: 1703次

Comparison of Microstructure and Corrosion Resistance of 431 Stainless Steel Coatings Prepared by Extreme High-Speed Laser Cladding and Conventional Laser Cladding

激光技术 超高速激光熔覆 耐蚀涂层 微观组织 耐蚀性 laser technology extreme high-speed laser cladding corrosion-resistant coating microstructure corrosion resistance

摘要

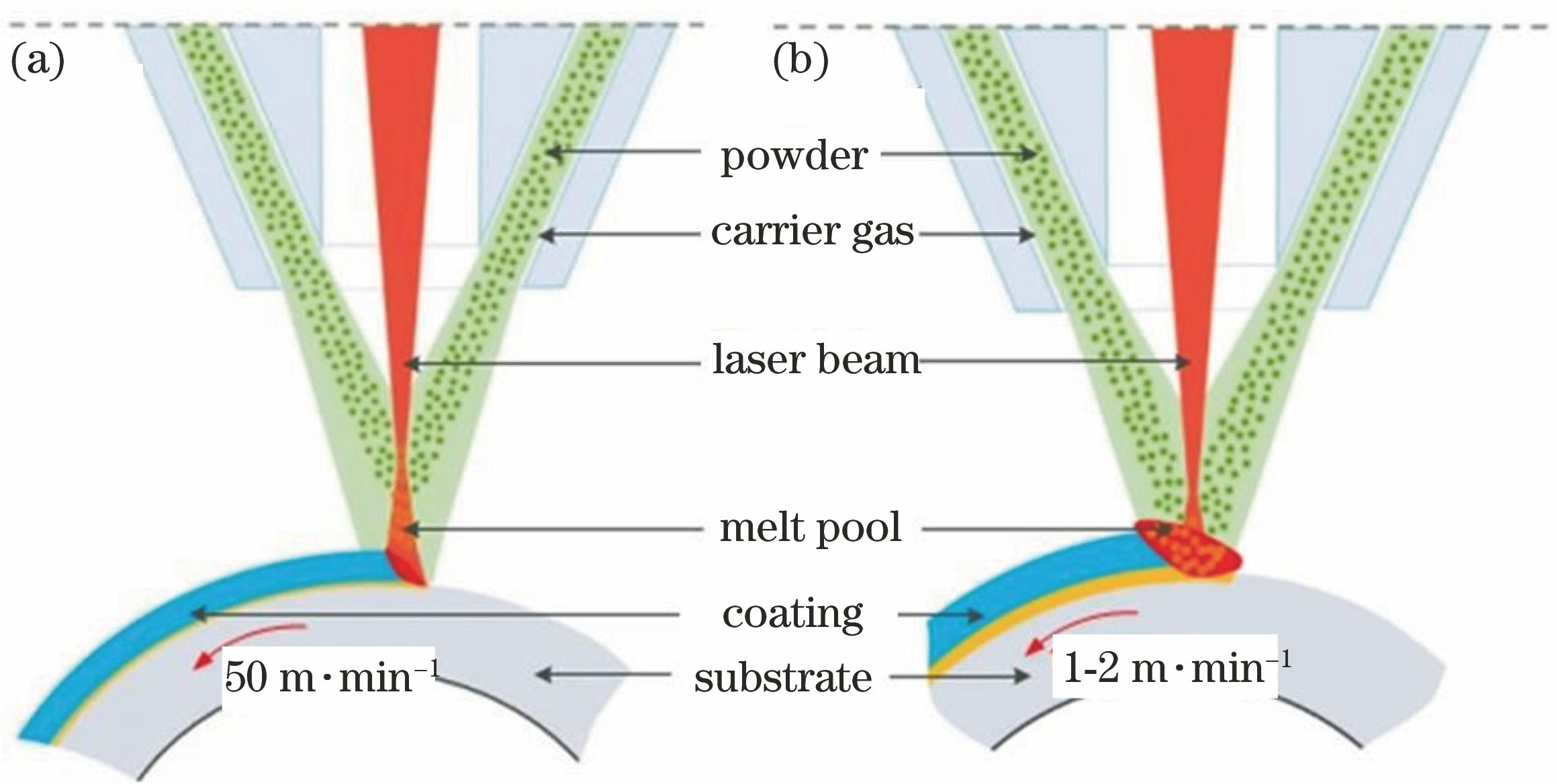

分别采用超高速(50 m/min)和常规(1.5 m/min)熔覆速度,在调质处理的27SiMn液压支架基材上成功制备了431不锈钢耐蚀涂层,对比分析了两种方法制备涂层的宏观特征、显微组织及耐蚀性能。试验结果表明:两种方法制备的涂层均无微观裂纹与气孔缺陷,且与基体形成了良好的冶金结合;相比于常规激光熔覆涂层,超高速激光熔覆的涂层具有类似“多米诺骨牌”的多层重叠结构,稀释率仅为4%,涂层中Cr的原子数分数为19%;常规激光熔覆涂层组织整体较为粗大,在搭接位置由于温度梯度的改变,枝晶生长方向紊乱;超高速激光熔覆涂层整体组织更加均匀细密,底部/基体界面结合区微观组织形态为平面晶,中部搭接区及表面为细小的树枝晶,仅在搭接位置略有粗化;采用超高速激光熔覆技术制备的涂层具有更加优异的耐蚀性能。

Abstract

Herein, a tempered 27SiMn hydraulic support substrate with 431 stainless steel corrosion-resistant coatings is successfully prepared by 50 m/min extreme high-speed laser cladding (EHLA) and 1.5 m/min conventional laser cladding (CLA) methods, respectively. The macroscopic features, microstructure, and corrosion resistance of the coatings prepared by both methods are comparatively investigated. Results show that the coatings prepared by both methods form good metallurgical bonds without microcracks and blowhole defects. Compared to the CLA coating, the EHLA coating has a multi-layer structure similar to the “dominoes” and a low dilution of 4%. Cr achieves a high atomic number fraction of 19% in the EHLA coating. The macroscopic structure of the CLA coating is relatively large, and the direction of dendrite growth is disordered due to the change of temperature gradient at the overlapping zone. The macroscopic structure of the EHLA coating has a high degree of uniformity and compactness, and the microstructure at the bottom/substrate interface is planar crystalline. The dendrites in the middle overlapping zone and the surface of the EHLA coating are finer and slightly roughened at the overlapping area. The corrosion resistance of the EHLA coating is significantly superior.

李俐群, 申发明, 周远东, 陶汪, 王威, 王树良. 超高速激光熔覆与常规激光熔覆431不锈钢涂层微观组织和耐蚀性的对比[J]. 中国激光, 2019, 46(10): 1002010. Liqun Li, Faming Shen, Yuandong Zhou, Wang Tao, Wei Wang, Shuliang Wang. Comparison of Microstructure and Corrosion Resistance of 431 Stainless Steel Coatings Prepared by Extreme High-Speed Laser Cladding and Conventional Laser Cladding[J]. Chinese Journal of Lasers, 2019, 46(10): 1002010.