激光与光电子学进展, 2019, 56 (23): 231402, 网络出版: 2019-11-27

基于响应面分析的激光除漆工艺参数优化  下载: 1033次

下载: 1033次

Laser Paint Removal Process Parameter Optimization via Response Surface Methodology

激光技术 激光除漆 响应面分析 工艺参数优化 304不锈钢 丙烯酸树脂漆 laser technique laser paint removal response surface methodology process parameter optimization 304 stainless steel acrylic resin paint

摘要

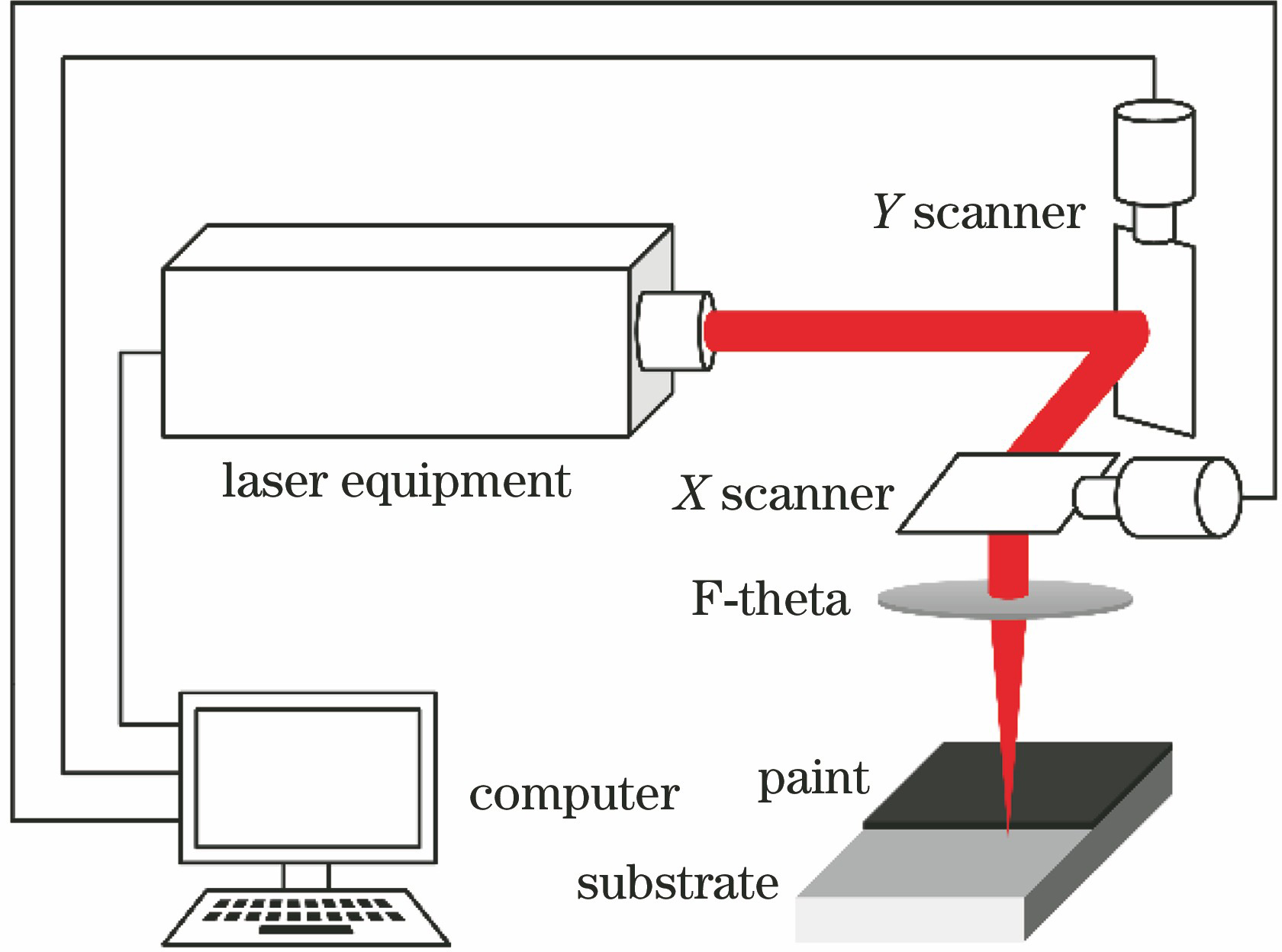

为了研究激光除漆工艺规律并优化工艺参数,采用纳秒脉冲激光器对304不锈钢基体表面的丙烯酸树脂漆进行激光清洗实验。采用扫描电子显微镜与X射线能谱仪分别对激光除漆后的表面微观形貌与成分进行分析,并使用激光共聚焦显微镜对除漆后的表面粗糙度进行测量。基于响应面分析法,使用Design-Expert软件研究激光功率、扫描次数和光斑搭接率对激光除漆后表面微观形貌、成分和表面粗糙度的影响规律,并对除漆工艺参数进行优化。研究发现:光斑搭接率对表面成分的影响最为显著,而激光功率对表面粗糙度的影响最为显著;优化结果显示,当激光功率为19.18 W、光斑搭接率为46%、扫描次数为3次时,激光除漆的效果最佳。采用合适的工艺参数进行激光除漆,可以获得较好的清洗效果。

Abstract

To study the laser cleaning process and optimize process parameters, a nanosecond pulse laser was used to perform laser cleaning experiments on the acrylic resin paint on the surface of a 304 stainless steel substrate. The surface morphology and elemental composition after paint removal were analyzed by using the scanning electron microscopy and X-ray energy dispersive spectroscopy, and the surface roughness was measured by using a laser confocal microscope. Based on the response surface methodology, a Design-Expert software was used to analyze the effects of laser power, number of scans, and spot overlap rate on the surface morphology, elemental composition, and surface roughness after laser paint removal, and the paint removal process parameters were optimized. The results denote that the spot overlap rate considerably affects the surface composition and that the laser power considerably affects the surface roughness. The optimization results denote that the optimal laser paint removal results can be achieved when the laser power is 19.18 W, the spot overlap rate is 46%, and the number of scans is 3. The experiments show that improved cleaning results can be obtained by selecting suitable process parameters.

杨嘉年, 周建忠, 孙奇, 孟宪凯, 朱明, 郭召恒, 付强. 基于响应面分析的激光除漆工艺参数优化[J]. 激光与光电子学进展, 2019, 56(23): 231402. Jianian Yang, Jianzhong Zhou, Qi Sun, Xiankai Meng, Ming Zhu, Zhaoheng Guo, Qiang Fu. Laser Paint Removal Process Parameter Optimization via Response Surface Methodology[J]. Laser & Optoelectronics Progress, 2019, 56(23): 231402.