激光与光电子学进展, 2019, 56 (18): 181402, 网络出版: 2019-09-09

阳极氧化铝表面激光处理工艺与机理  下载: 1133次

下载: 1133次

Laser Surface Processing on Anodic Aluminum Oxide

激光技术 激光表面处理 加工参数 形貌变化 高对比度 高色差 laser technology laser surface processing processing parameters change of micro-morphology high contrast high chromatic aberration

摘要

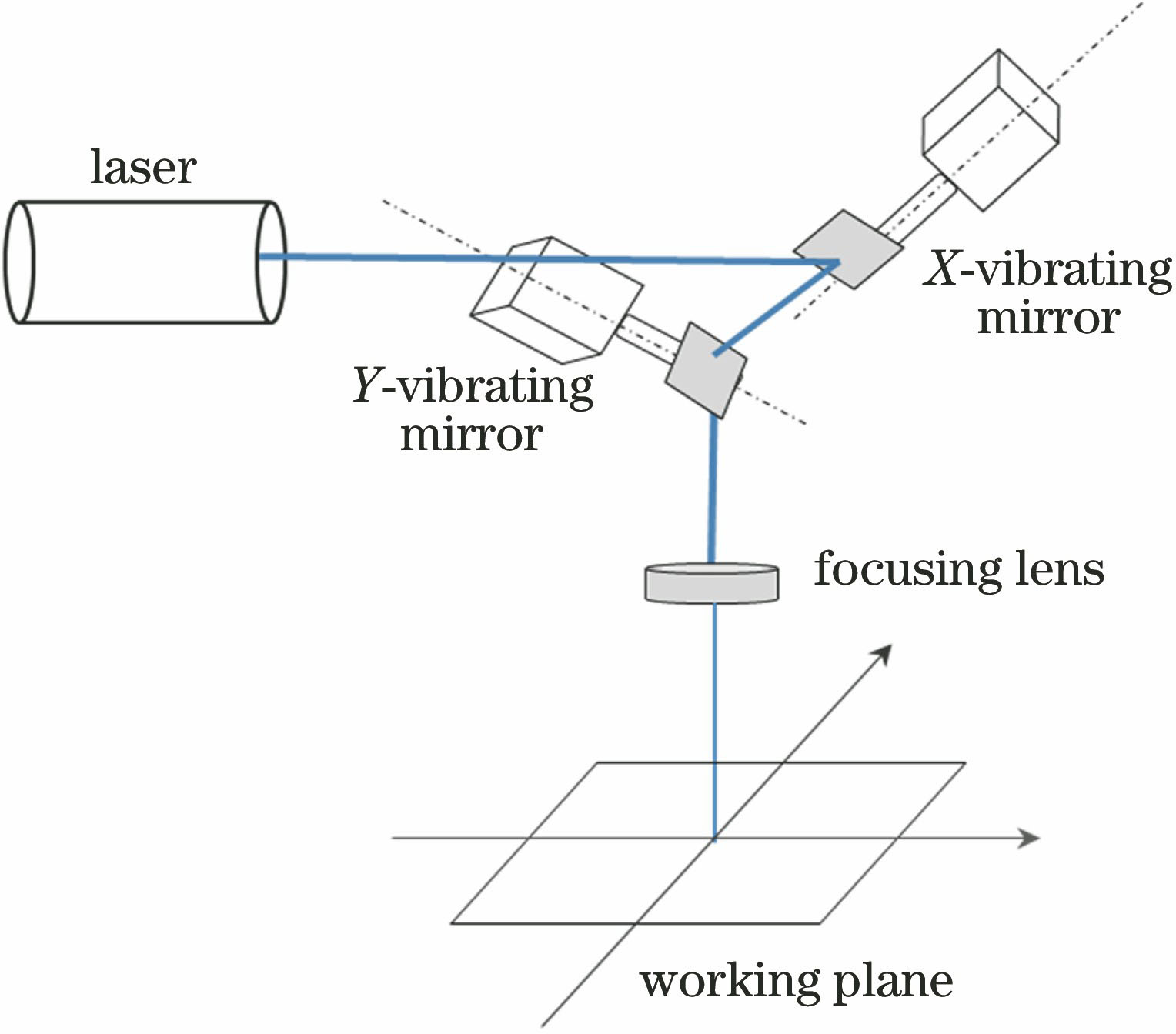

为了解决铝材表面激光处理无法形成高色差、高对比度的黑色图形问题,以阳极氧化5052铝合金为研究对象,选用脉冲宽度为4 ns的光纤激光器,设定扫描速度为130 mm/s,频率为300 kHz,扫描间距为0.005 mm,设定功率为27%P 0~33%P 0(P 0为激光器的额定功率),以得到高色差、高对比度的黑色图形,研究激光功率对图形对比度及微观形貌的影响,分析阳极氧化铝表面激光处理形成图形的机理。结果表明:当激光功率超过1.64 W时,激光能量达到铝材熔化阈值,材料表面开始形成图形,随着功率的增大,对比度逐渐上升;当激光功率增大到2.13~2.76 W时,铝材表面熔化与蒸发形成细裂纹的微观形貌,宏观显示为黑色,对比度达到最大;激光功率增大至3.32 W后,铝材表面完全熔化,细裂纹形貌消失,宏观显示为灰白色,对比度下降。该技术有助于激光与铝材作用机理的进一步研究,对推动物联网技术的发展具有重要意义。

Abstract

To solve the problem of laser surface processing not forming high-chromatic-aberration and high-contrast black patterns on aluminum alloys, a fiber laser machine with a 4-ns pulse width is used to mark 5052 anodic aluminum oxide (AAO) alloy at a scanning speed of 130 mm/s, a frequency of 300 kHz, a scanning pitch of 0.005 mm, and a setup power of 27%P0-33%P0 (P0 is the rated power of the laser). We obtain a black pattern with a high chromatic aberration and high contrast. The effect of the laser power on the contrast and micro-morphology of the pattern is studied, and the mechanism of pattern formation by laser surface processing on the AAO is analyzed. Results show that when the laser power exceeds 1.64 W, the laser energy reaches the melting threshold of aluminum and a pattern is formed on the surface. With the increase of laser power, the contrast gradually increases. When the laser power increases to 2.13-2.76 W, the AAO surface forms a fine-crack micro-morphology by melting and evaporation, the macroscopic display is black, and the contrast reaches the maximum. When the laser power increases to 3.32 W, the surface of the aluminum material melts completely, the fine-crack micro-morphology disappears, the macroscopic display is grayish white, and the contrast decreases. These results contribute to further research on the mechanism of laser surface processing on aluminum, which is helpful for promoting the development of the Internet of Things.

李彤彤, 沈宝东, 李重河, 兰豹豹, 陈光耀. 阳极氧化铝表面激光处理工艺与机理[J]. 激光与光电子学进展, 2019, 56(18): 181402. Tongtong Li, Baodong Shen, Chonghe Li, Baobao Lan, Guangyao Chen. Laser Surface Processing on Anodic Aluminum Oxide[J]. Laser & Optoelectronics Progress, 2019, 56(18): 181402.