激光与光电子学进展, 2020, 57 (22): 221013, 网络出版: 2020-11-12

基于线结构光的核燃料棒表面裂缝尺寸测量  下载: 828次

下载: 828次

Surface Crack Size Detection in Nuclear Fuel Rods Based on Line Structured Light

图像处理 线结构光 表面裂缝 水平投影 种子点判断法 最小二乘法 距离采样 image processing structured light surface crack horizontal projection seed point judgment least squares distance sampling

摘要

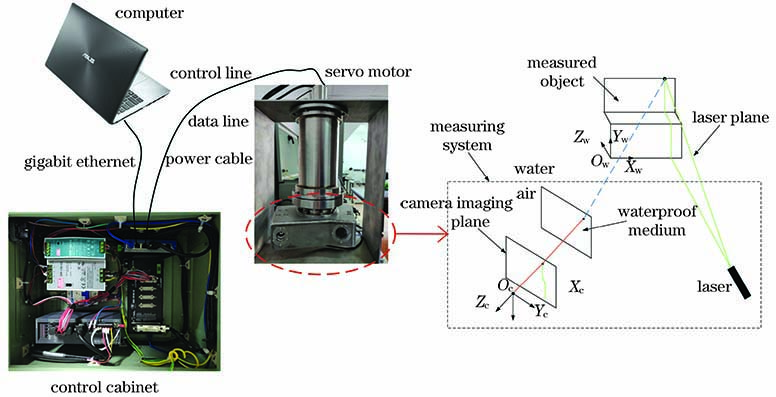

为实现复杂水下环境中裂缝尺寸的准确测量,提出了一种基于线结构光的核燃料棒表面裂缝尺寸测量方法。首先,对获取的图像进行灰度二维搜索,框选出待处理区域,再对该区域进行水平投影和一阶微分,进一步确定裂缝区域;然后,对裂缝区域进行阈值分割以缩小该区域范围,再利用种子点判断法确定出裂缝的上下边界;最后,使用最小二乘法拟合结构光中心线,用中心线方程与裂缝边界点集求交点来确定裂缝的具体位置,再将裂缝边界点转化为三维坐标进行距离采样,计算实际尺寸。实验结果表明使用该方法能精确快速测量出燃料棒表面裂缝的尺寸,并且使误差保持在0.03mm以内,可有效满足测量的便捷性和精确性。

Abstract

To accurately measure the crack size on the surface of nuclear fuel rods in a complex underwater environment, a method based on linear structured light is proposed. First, a two-dimensional grayscale search is performed on the acquired image to select the area to be processed, and then to further determine the crack area by horizontal projection and first-order differentiation. Then, threshold division of the crack area is performed to reduce the range of this area, and the upper and lower boundaries of crack are determined using the seed point judgment method. Finally, the least squares method is used to fit the centerline of structured light, the intersection point calculated by the centerline equation and the crack boundary point set is used to determine the specific location of crack, and then, the crack boundary point is converted into three-dimensional coordinates for distance sampling to calculate the actual size of the crack. Experiments demonstrate that the proposed method can accurately and quickly measure the crack size of a fuel rod with an error within 0.03mm, making this method appealing and convenient.

咸凯强, 庞静珠, 胡俊. 基于线结构光的核燃料棒表面裂缝尺寸测量[J]. 激光与光电子学进展, 2020, 57(22): 221013. Kaiqiang Xian, Jingzhu Pang, Jun Hu. Surface Crack Size Detection in Nuclear Fuel Rods Based on Line Structured Light[J]. Laser & Optoelectronics Progress, 2020, 57(22): 221013.